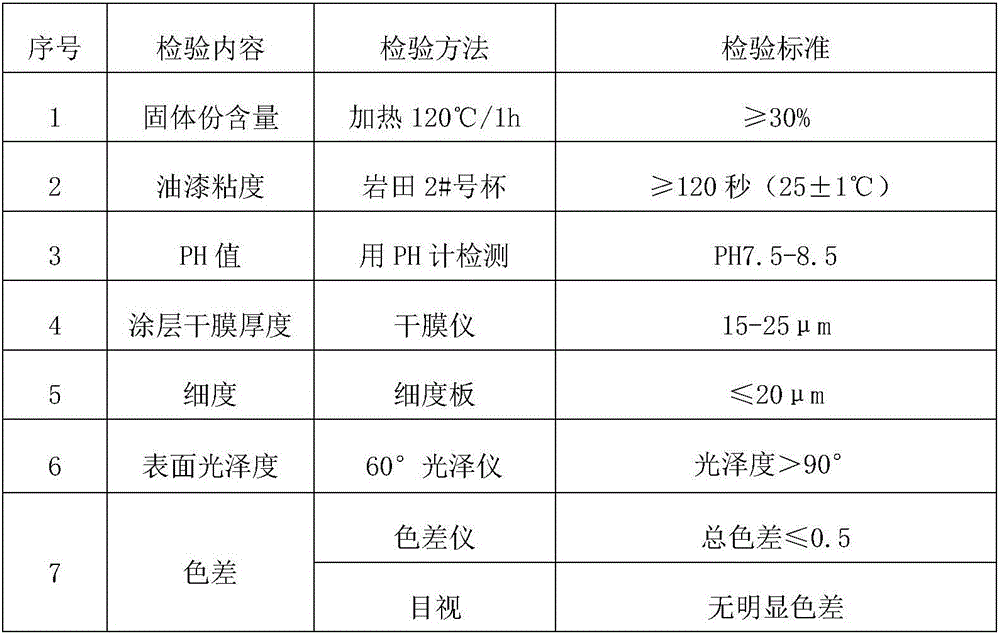

Waterborne paint for winebottles and preparation method thereof

A technology for water-based coatings and wine bottles, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve problems such as environmental pollution, achieve low glass transition temperature, improve adhesion and chemical resistance, and high hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

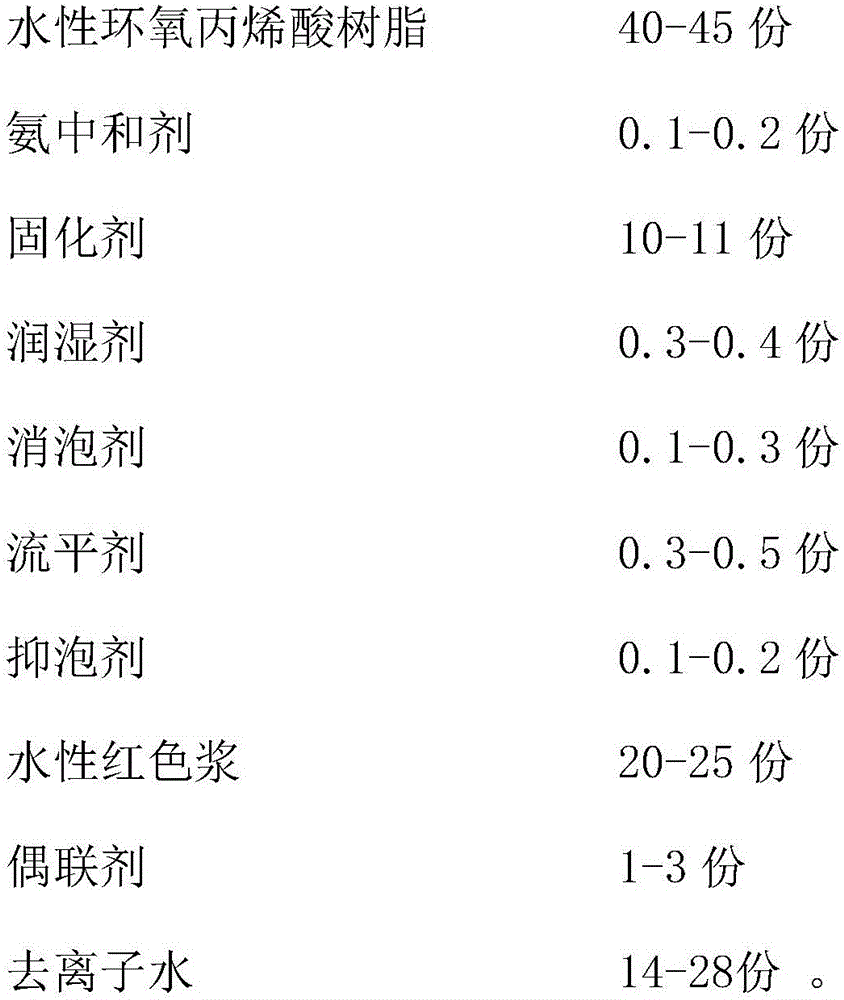

[0032] A kind of water-based coating that is used for wine bottle surface coating, the preparation method of this water-based coating, the steps are as follows:

[0033] 1) Add 40 parts of water-based epoxy acrylic resin of model WA-360E to the container by weight, then stir with a high-speed disperser, gradually add 0.1 part of ammonia neutralizer dropwise while stirring, and the stirring speed is 500r / min, After stirring for 4 minutes, test that the pH value of the mixed liquid is 8.0, stop stirring, and proceed to the next step;

[0034] 2) Add 10 parts of INEOS-R717 partially methylated amino resin curing agent, 0.3 parts of TEGO-270 wetting agent, 0.3 parts of EFKA-3772 leveling agent, 0.1 parts into the container in sequence 1 part of antifoaming agent of BYK-028 model, 0.1 part of antifoaming agent of Surfynol 104E, and then stir with a high-speed disperser at a stirring speed of 500r / min, and disperse for 5 minutes;

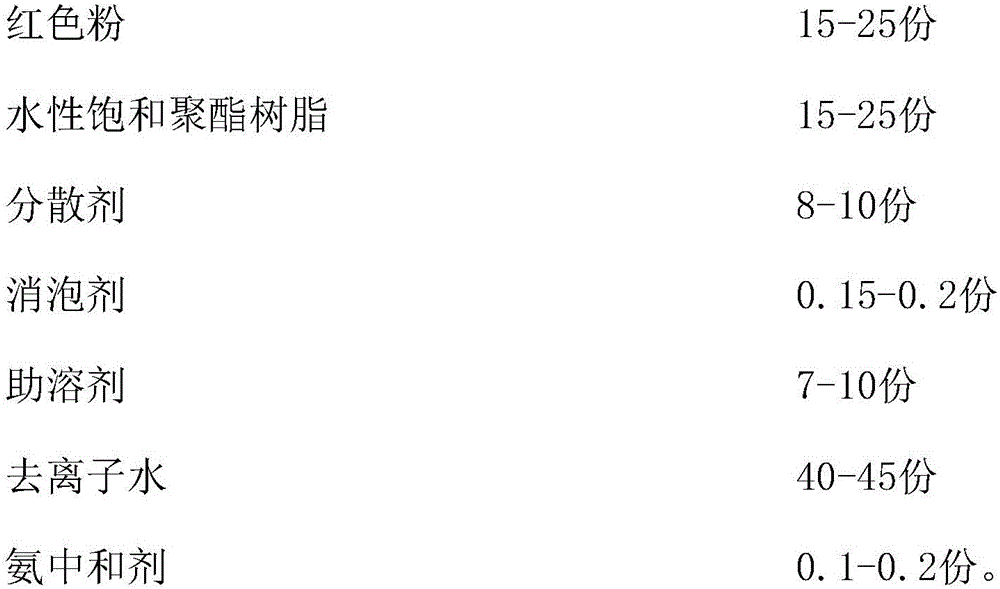

[0035] 3) Add 20 parts of water-based red paste an...

Embodiment 2

[0041] A kind of water-based coating that is used for wine bottle surface coating, the preparation method of this water-based coating, the steps are as follows:

[0042] 1) Add 42 parts of water-based epoxy acrylic resin to the container by weight, then stir with a high-speed disperser, gradually add 0.15 parts of ammonia neutralizer dropwise while stirring, the stirring speed is 700r / min, after 5min, test the mixed liquid When the pH value is 8.4, stop stirring and proceed to the next step;

[0043] 2) Add 10.6 parts of INEOS-R717 partially methylated amino resin curing agent, 0.35 parts of TEGO-270 wetting agent, 0.4 parts of EFKA-3772 leveling agent, 0.2 parts into the container in sequence One part model is BYK-028 defoamer, 0.15 part model is Surfynol 104E antifoam agent, then stir with high-speed disperser, stirring speed is 700r / min, disperse for 7 minutes;

[0044] 3) Add 22 parts of water-based red paste and 2 parts of coupling agent to the container, and finally add...

Embodiment 3

[0050] A kind of water-based coating that is used for wine bottle surface coating, the preparation method of this water-based coating, the steps are as follows:

[0051] 1) Add 45 parts of water-based epoxy acrylic resin to the container by weight, then stir with a high-speed disperser, gradually add 0.2 parts of ammonia neutralizer dropwise while stirring, the stirring speed is 800r / min, after 6min, test the mixed liquid When the pH value is 8.5, stop stirring and proceed to the next step;

[0052] 2) Add 11 parts of INEOS-R717 partially methylated amino resin curing agent, 0.4 parts of TEGO-270 wetting agent, 0.5 parts of EFKA-3772 leveling agent, 0.3 parts into the container One part model is defoamer BYK-028, 0.2 part model is antifoam agent Surfynol 104E, then stir with high-speed disperser, stirring speed is 800r / min, disperse for 10 minutes;

[0053] 3) Add 25 parts of water-based red paste and 3 parts of coupling agent to the container, and finally add 16 parts of deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com