Shale oil deep processing method

A technology for deep processing of shale oil, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, etc., and can solve problems such as low yield of light oil products, insufficient processing depth, complex shale oil deep processing process, etc. , to achieve the effect of expanding feed material sources and operating rate, improving utilization efficiency, improving overall efficiency and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

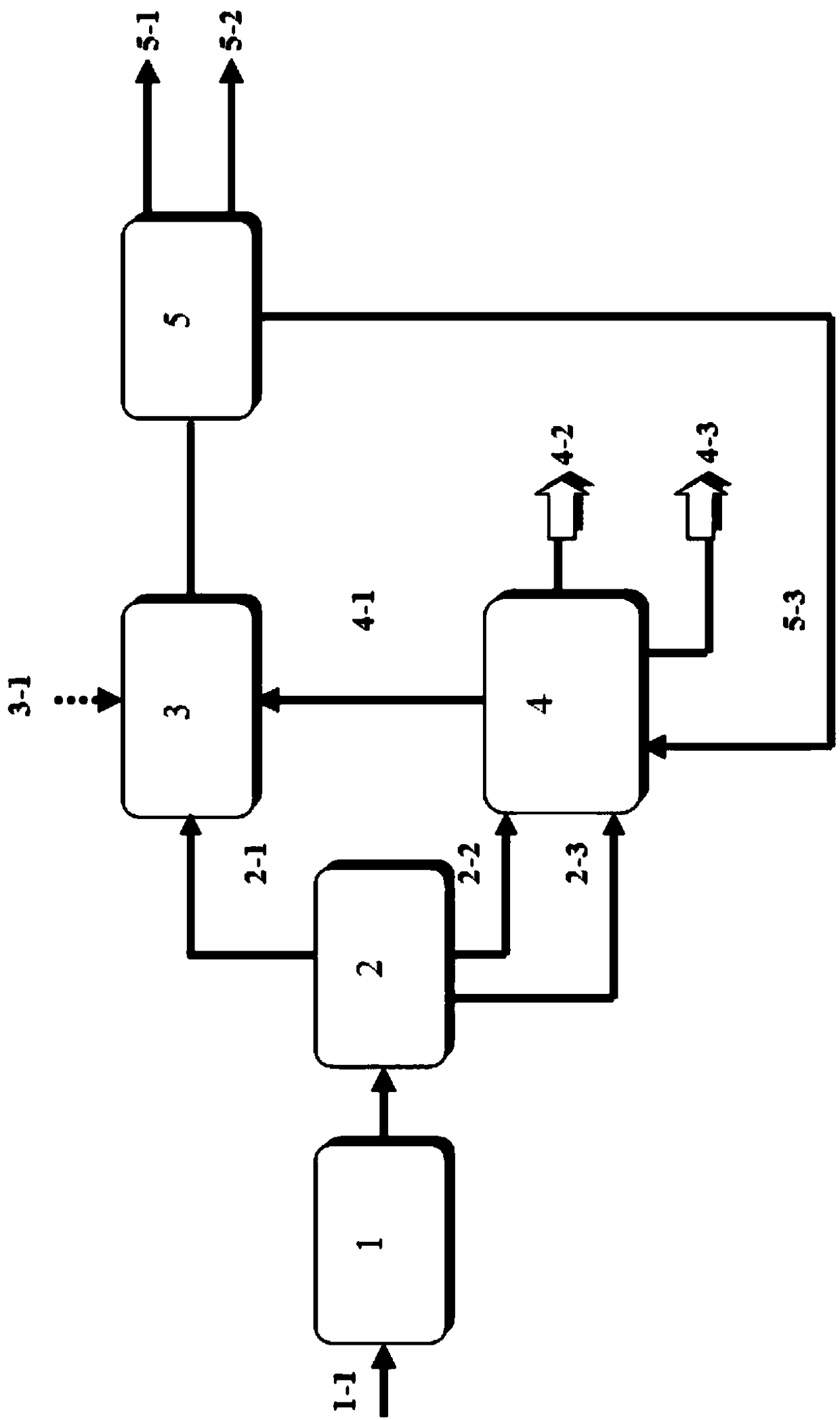

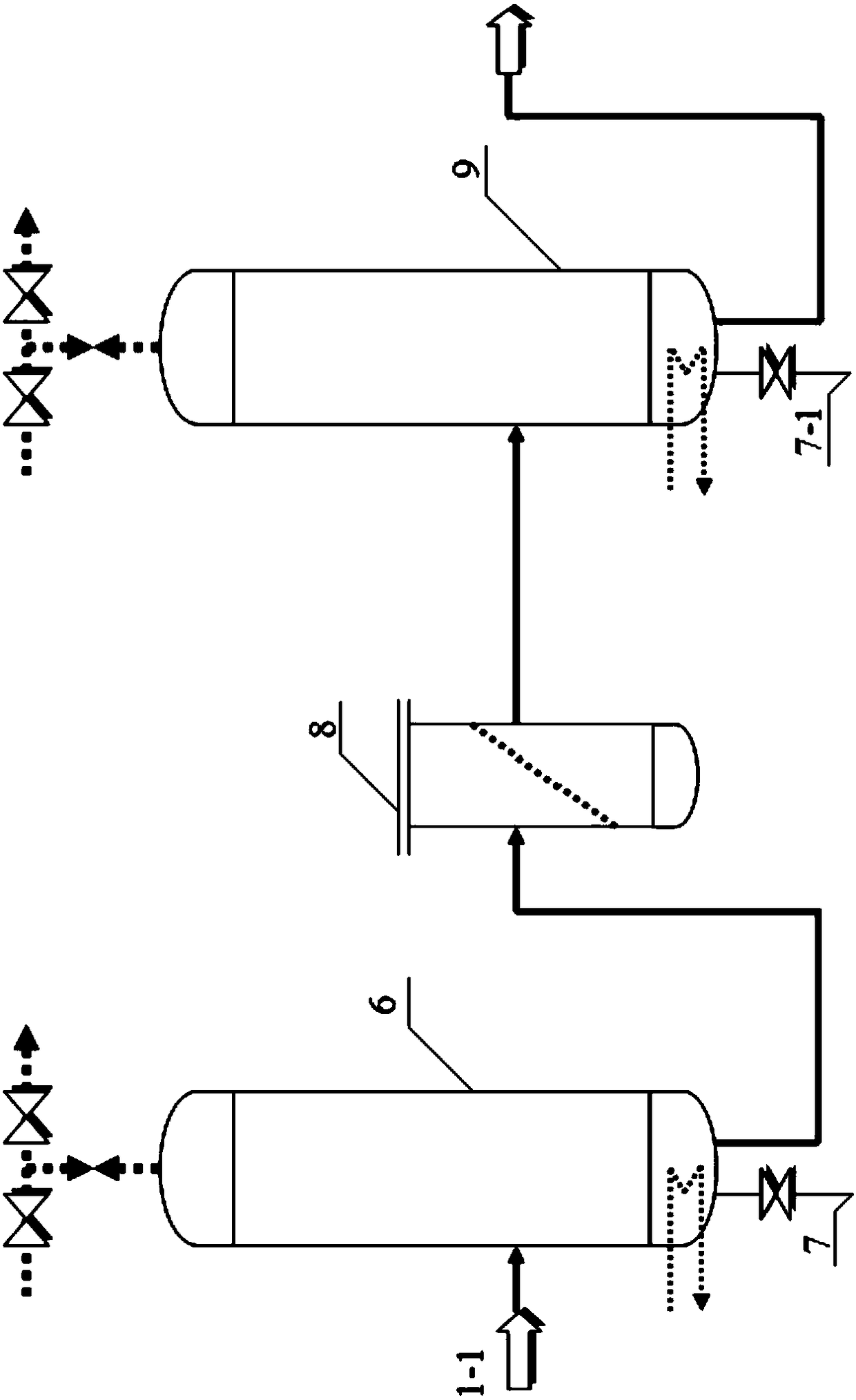

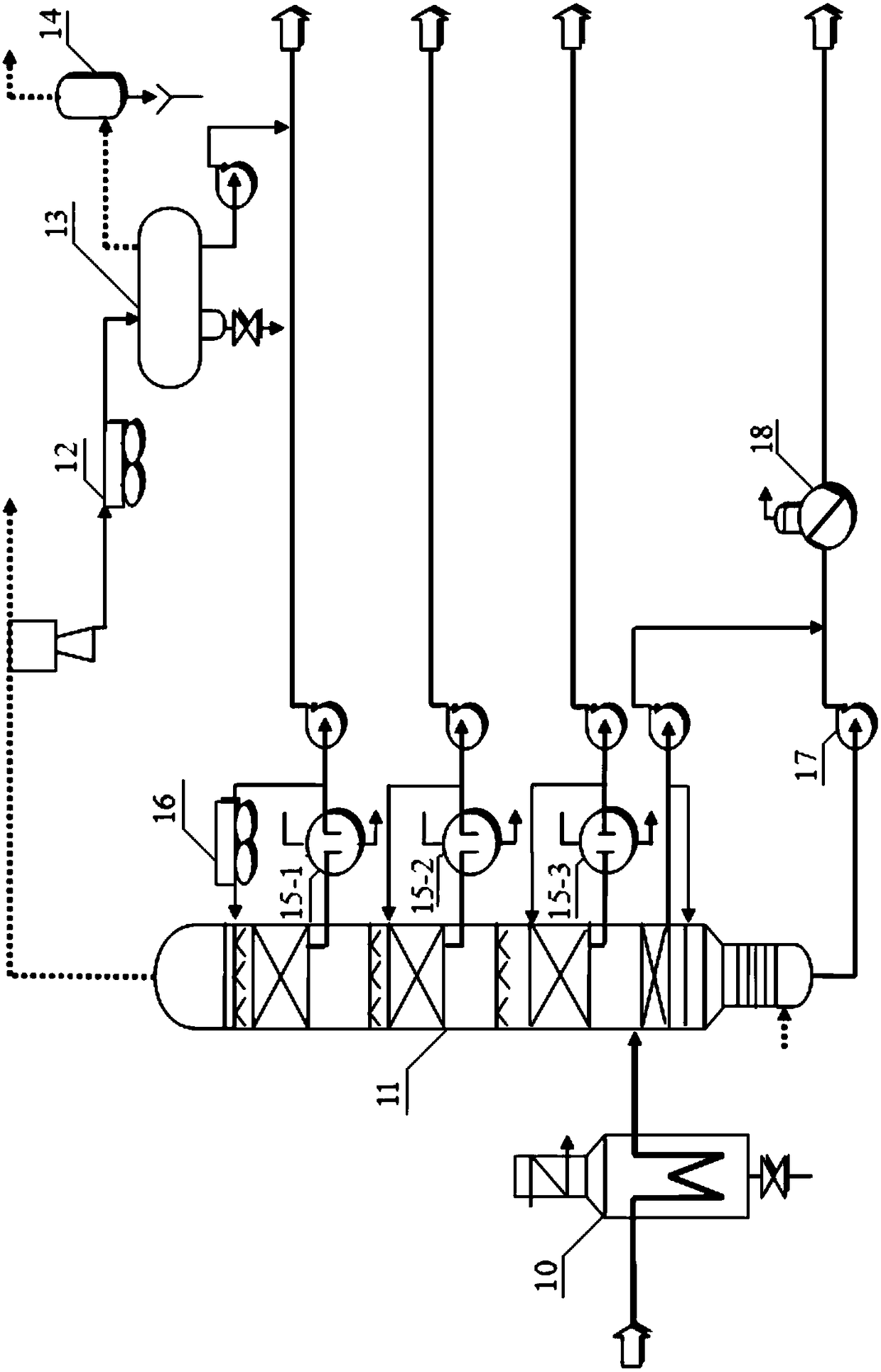

[0074] The full fraction shale oil 1-1 from the tank area enters the raw material pretreatment unit 1 for raw material pretreatment; the pretreated full fraction shale oil enters the vacuum distillation unit 2 to separate the light vacuum distillate 2-1, The heavy vacuum distillate oil 2-2 and the vacuum residue oil 2-3; the light vacuum distillate oil 2-1 enters the hydrorefining unit 3 and undergoes catalytic hydrogenation reaction with hydrogen gas 3-1 and catalyst in the hydrogenation reactor, The generated hydrogenated oil enters the product fractionation unit 5; the heavy vacuum distillate oil 2-2 and the vacuum residue 2-3 are mixed with the hydrogenated tail oil 5-3 separated from the product fractionation unit 5 and enters the delayed coking reaction unit 4. Carry out cracking and condensation reactions, and the generated coking distillate oil 4-1 enters the hydrorefining reaction unit 3 for back refining, and the generated coking heavy wax oil 4-2 and coke 4-3 leave t...

specific Embodiment approach 2

[0119] Specific embodiment two: this embodiment is different from specific embodiment one in that the vacuum distillation tower described in step two has a specification of φ6200×35000mm (cut), and 4 sections of structured packing are arranged inside. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0120] Specific embodiment three: the difference between this embodiment and one of the specific embodiments one or two is that the extraction temperature of the first-line diesel oil in step two is 365-375°C, the extraction temperature of the second-line wax oil is 445-455°C, and the extraction temperature of the third-line The extraction temperature of wax oil is 490-510°C. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com