Preparing and application method of high-strength waterproof briquette coal adhesive

A water-resistant, high-strength technology, used in the petroleum industry, solid fuels, fuels, etc., can solve the problems of a large drop in the cooling strength of briquette, affecting the use of briquette, and poor waterproof performance, achieving excellent waterproof performance and reducing waste. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with embodiment.

[0023] 1) the preparation of a kind of high-strength water-resistant briquette binder of the present invention comprises the following steps:

[0024] Mix cement with a mass ratio of 23-35% and concrete quick-setting agent with a mass ratio of 5-13% in the reactor, and mix sodium humate with a mass ratio of 40-65%, 1-5% The sodium compound is slowly added therein, and the red clay with a mass ratio of 8-20% is finally added into the reactor during the stirring process and fully stirred to obtain the briquette binder.

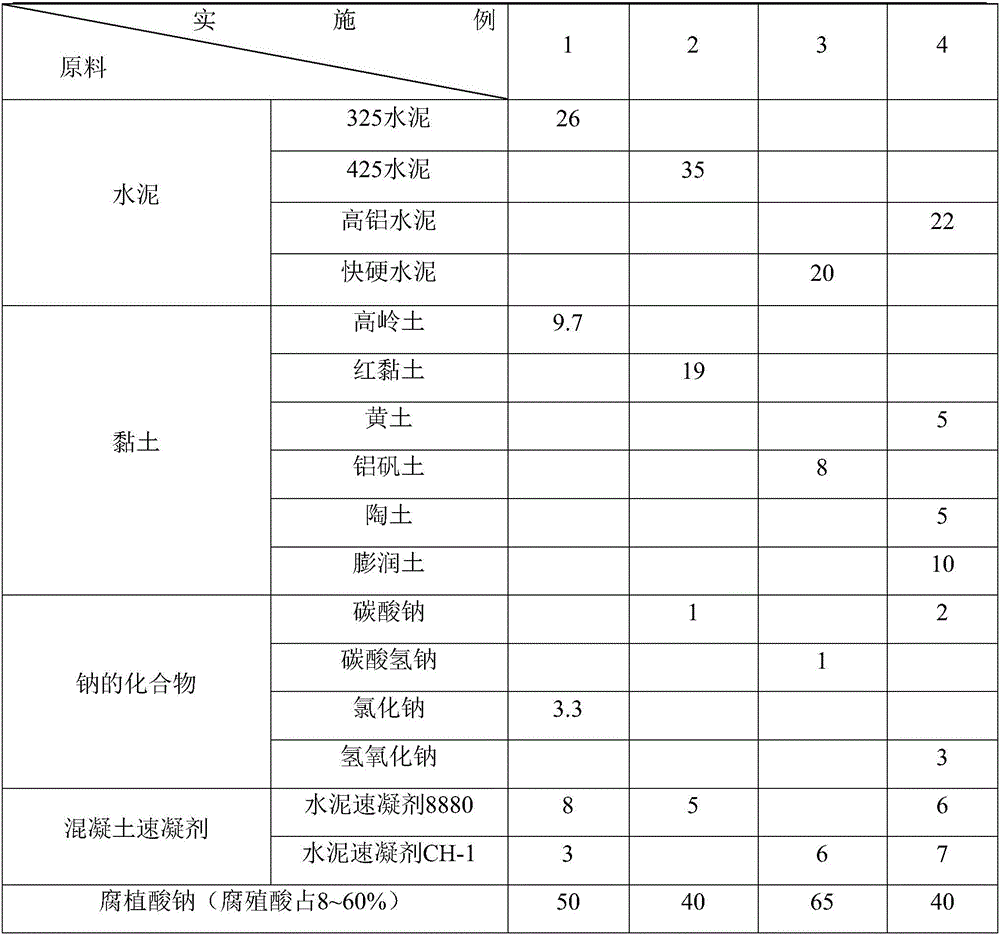

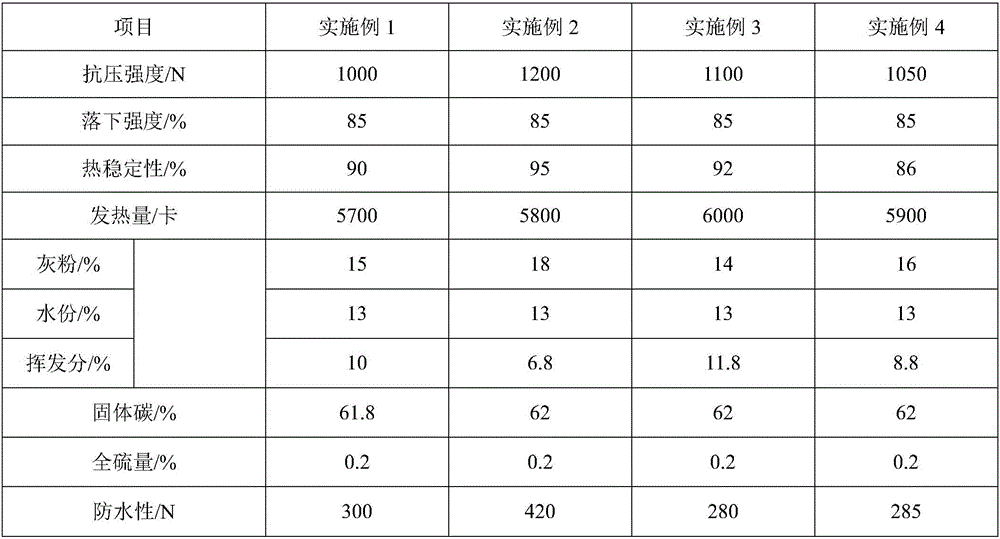

[0025] Embodiment proportioning table 1 below

[0026] Attached Table 1: Examples of different raw material ratios

[0027]

[0028] 2) Application of briquette binder in coal powder

[0029] Weigh 80-150g of pulverized coal with a particle size of 1-3mm and put it into a beaker, then weigh 2-5g of briquette binder and slowly add it into it and stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com