Method and power system for driving automobile through high-pressure hydrogen mixed fuel

A hybrid fuel and power system technology, applied in the direction of fuel system, charging system, combustion engine, etc., can solve the problems of environmental impact, limited petroleum fuel reserves, high cost of hydrogen energy storage and transportation, and achieve the goal of improving thermal efficiency and energy utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

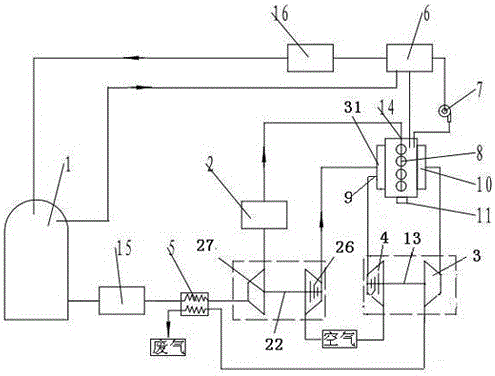

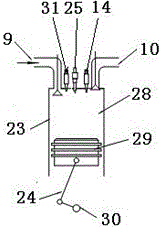

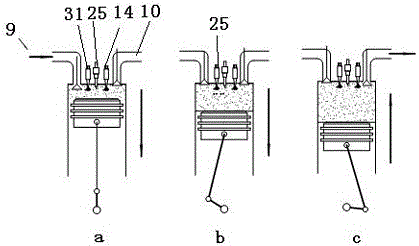

[0028] The present invention utilizes high-pressure hydrogen mixed fuel to drive the power system of the automobile such as figure 1 As shown, it includes a hydrogen mixed fuel storage tank 1, a heat storage device 6, a circulation pump 7, a high pressure stabilizing pump 16, a dehydration dryer 15, a heat exchanger 5 and a cold storage device 2, a piston gas engine 8, a turbocharger Unit 13, number 2 turbo unit 22 and air lines. The turbocharger unit is provided with an expander 3 and a supercharger 4, the expander and the supercharger are coaxially connected, the No. 2 turbocharger unit is provided with a No. 2 supercharger 26 and a No. 2 expander 27, and the No. 2 supercharger The machine is coaxially connected with the No. 2 expander. The piston gas engine is provided with an air inlet 9, a gas inlet 14, an exhaust gas outlet 10, and a power output shaft 11. The cold storage device is equipped with a cold storage agent, the heat storage medium in the heat storage device ...

Embodiment 2

[0034] Another embodiment of the present invention is as Figure 4 As shown, it includes a hydrogen mixed fuel storage tank 1, a piston gas engine 8, a turbocharger unit 13, a pressure energy utilization control unit 12, a heat storage device 6, a cold storage device 2 and an air pipeline. The turbocharger unit is provided with an expander 3 and a supercharger 4, and the expander and the supercharger are coaxially connected. The piston gas engine is provided with an air inlet 9, a gas inlet 14, an exhaust gas outlet 10, and a power output shaft 11. The pressure energy is connected with the cold storage equipment through the control unit to form a circulation loop. The hydrogen mixed fuel storage tank is connected to the gas inlet of the piston gas engine through the pressure energy utilization control unit, the air pipeline is connected to the air inlet of the piston gas engine through a supercharger, and the exhaust gas outlet of the piston gas engine is connected to the tur...

Embodiment 3

[0040] The third embodiment of the present invention is as Figure 5 As shown, it includes a hydrogen mixed fuel storage tank 1, a piston gas engine 8, a turbocharger unit 13, a heat storage device 6, a cold storage device 2, a refrigeration pressure regulating device 19, a power generation expander 17, a generator 18 and a high-pressure expansion The turbocharger unit 13 is provided with an expander 3 and a supercharger 4, the high-pressure expander is coaxially connected with the expander and the supercharger, and the power generation expander is coaxially connected with the generator. The piston gas engine is provided with an air inlet 9, a gas inlet 14, an exhaust gas outlet 10, and a power output shaft 11. The refrigeration and pressure regulating equipment is connected with the cold storage equipment to form a circulation loop. The hydrogen mixed fuel storage tank is connected to the high-pressure expander through refrigeration and pressure regulating equipment, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com