Primitive Curve Modeling Method of Compressor Blade Suction Surface Based on Second-order Ordinary Differential Equation

A technology of ordinary differential equations and modeling methods, applied in the field of computer-aided geometric design, can solve problems such as error and parameter sensitivity, uncontrollability, loss of optimization meaning, etc., to achieve the effect of optimizing the operating space and reducing the degree of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

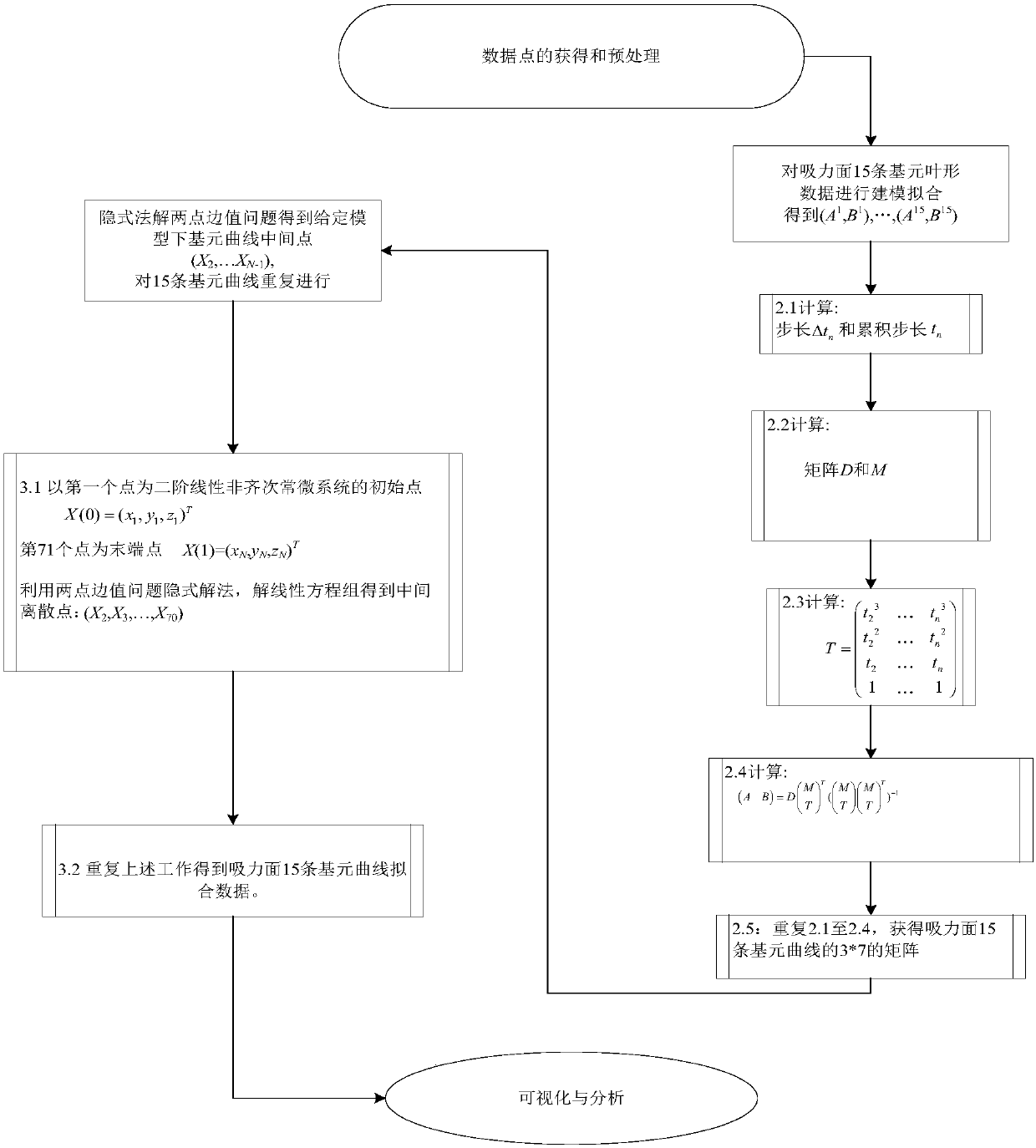

[0038] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0039] The present invention is based on a second-order ordinary differential equation modeling method for the primitive curve of the suction surface of a compressor blade, the process of which is as follows figure 1 As shown, each step is described below.

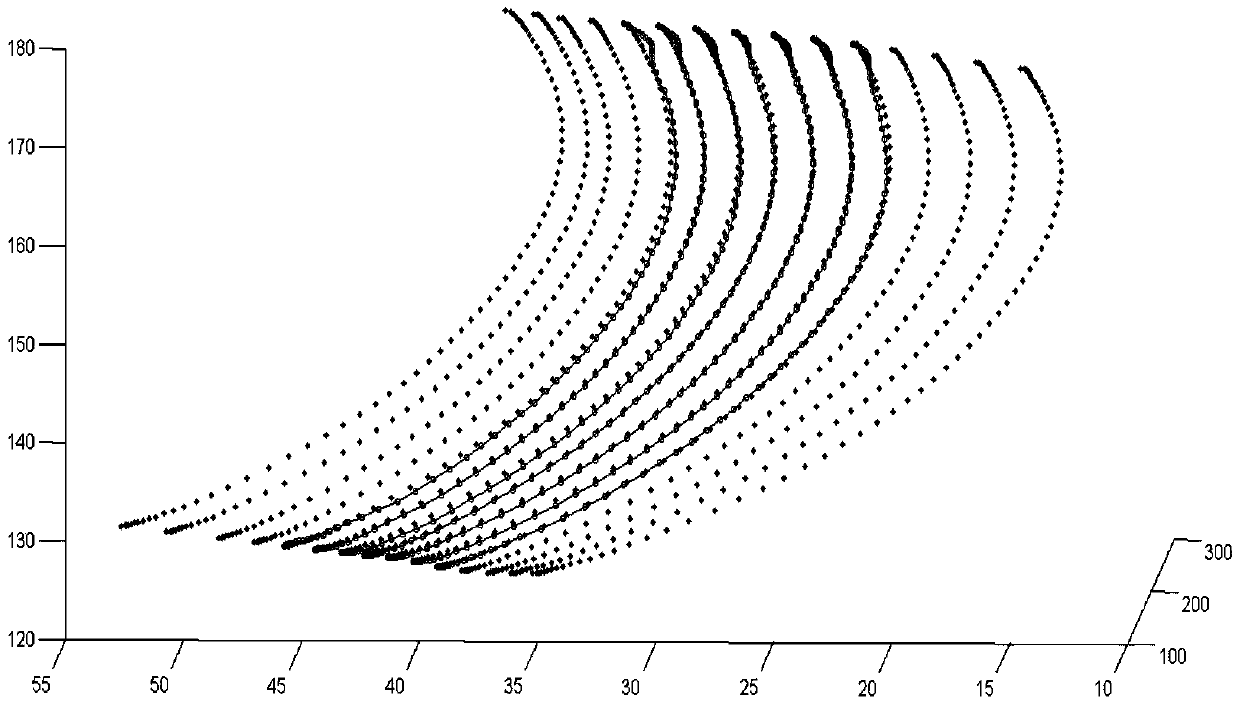

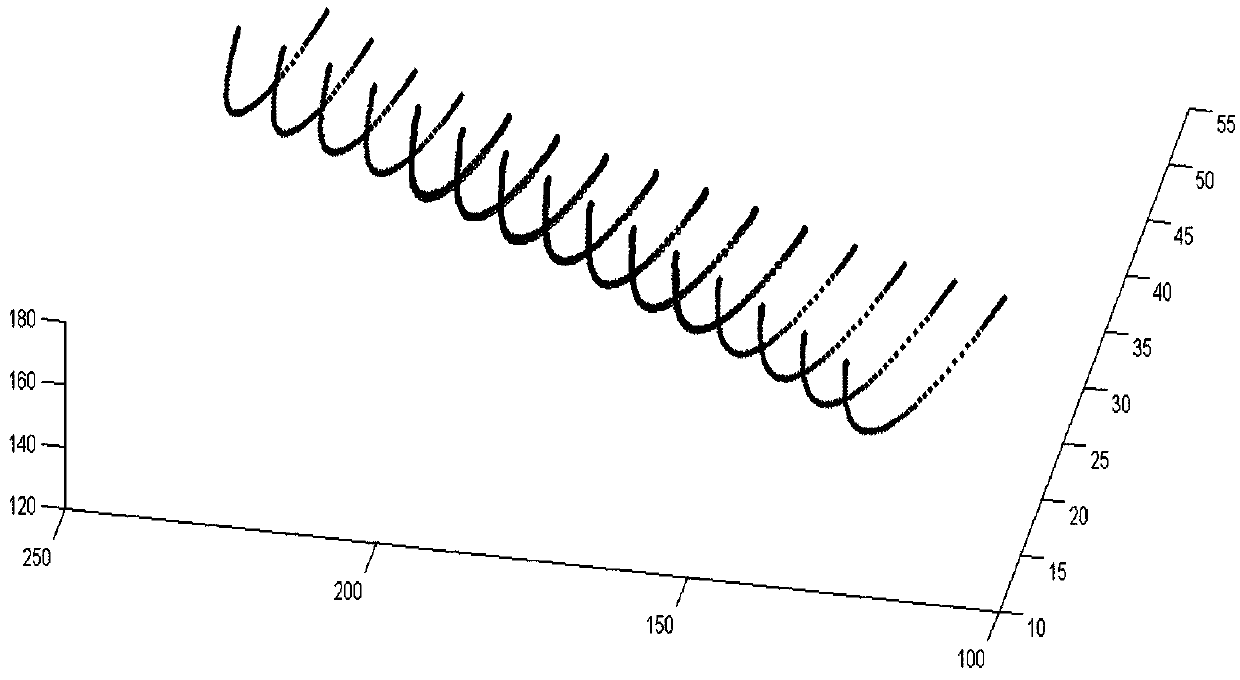

[0040] Step 1: Obtain the compressor blade suction surface data set, and perform modeling and simulation on the suction surface primitive blade shape data.

[0041] (1) Acquisition and preprocessing of data points.

[0042] The invention processes the data obtained from the preliminary design of the compressor blade, and imports the data set of the suction surface of the compressor blade.

[0043] Firstly, the data is preprocessed, including: unifying the scale of the obtained data set; placing it in a suitable coordinate system through appropriate coordinate transformation; removing redundant o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com