Thin film transistor and fabrication method thereof

A technology of thin film transistor and manufacturing method, applied in transistor, semiconductor/solid-state device manufacturing, semiconductor device and other directions, can solve the problems of long time, complicated process and increased production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

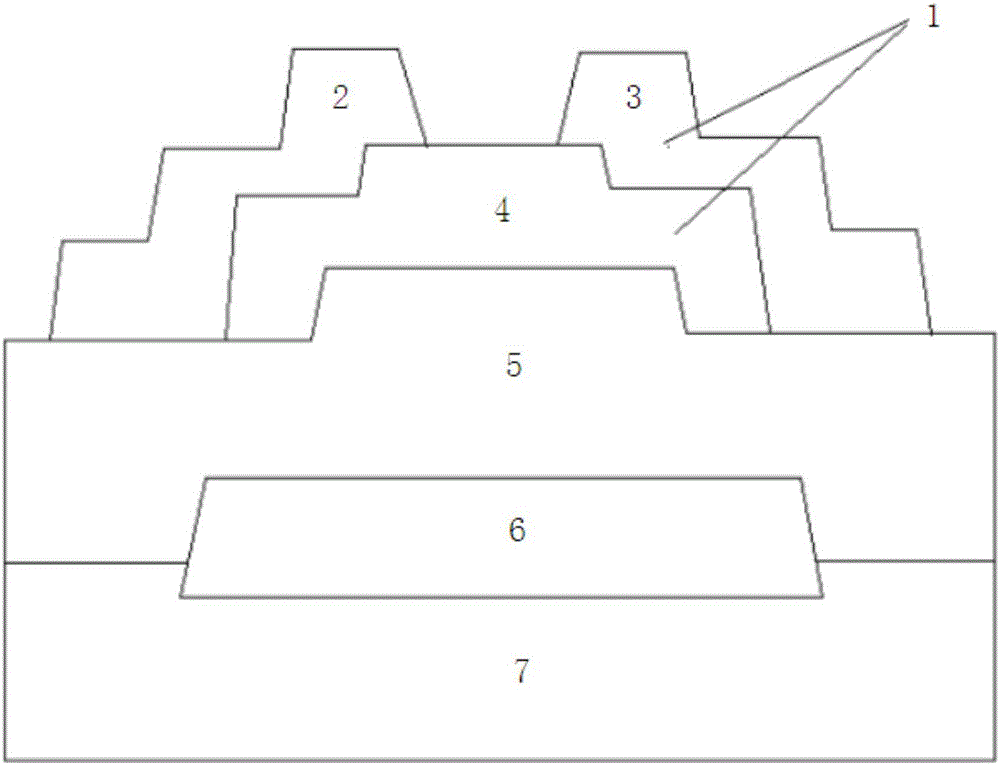

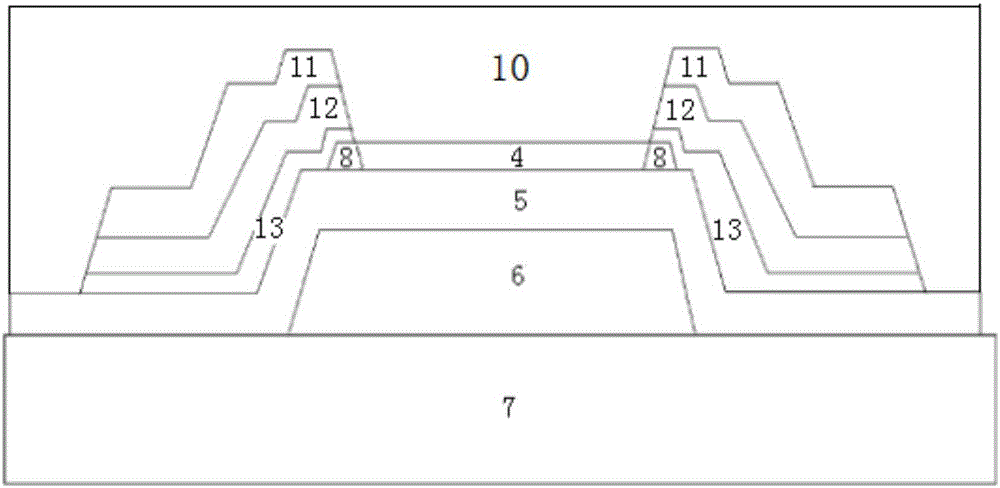

[0034] image 3 It is the structural diagram of the thin film transistor of the present invention, and the gate layer 6, the gate insulating layer 5, the indium gallium zinc oxide layer 4, the source and the drain are arranged sequentially from the inside to the outside, and the source and the drain are respectively arranged in sequence from the inside to the outside There is a first metal layer 13 , a second metal layer 12 and a third metal layer 11 , wherein the first metal layer 13 is in contact with the indium gallium zinc oxide layer 4 .

[0035] As a further improvement, the first metal layer 13 is metal indium, the second metal layer 12 is one of metal molybdenum or titanium, and the third metal layer 11 is one of metal copper or aluminum.

[0036] As a further improvement, a passivation layer 10 is provided above the source electrode, the drain electrode and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com