Low surfactant, high carbonate liquid laundry detergent compositions with improved suds profile

一种衣物洗涤剂、组合物的技术,应用在表面活性洗涤剂组合物、洗涤剂组合物、非离子表面活性化合物等方向,能够解决不期望等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

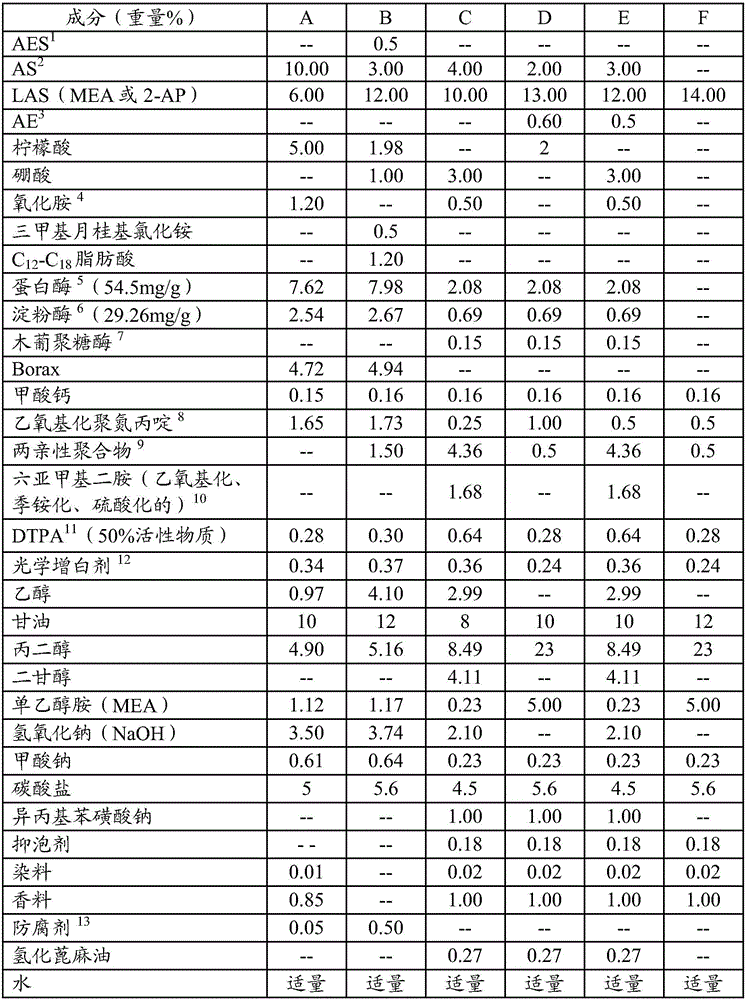

[0078] Example I. Exemplary Liquid Detergent Compositions

[0079] Six (6) exemplary liquid laundry detergent compositions A-F comprising low levels of LAS and high levels of sodium carbonate as described herein above were formed by the following steps:

[0080] 1. First form a solvent environment by adding water, glycerin, propylene glycol, etc.

[0081] 2. Add citric acid and MEA.

[0082] 3. The polymer is added using the heat generated by the neutralization reaction between citric acid and MEA.

[0083] 4. Add surfactant and mix well.

[0084] 5. Adjust the pH of the mixture to greater than 7 and then add sodium carbonate.

[0085] 6. Add beautifying agents (perfumes, dyes, etc.) and make up the formulation to 100% with water.

[0086] The composition of these 6 exemplary liquid laundry detergent compositions is provided below:

[0087] Form I :

[0088]

[0089] 1 AES can be AE 1 S, AE 15 S, AE 2 S, and / or AE 3 S, its amount is 0-20%.

[0090] 2 Straight...

Embodiment 2

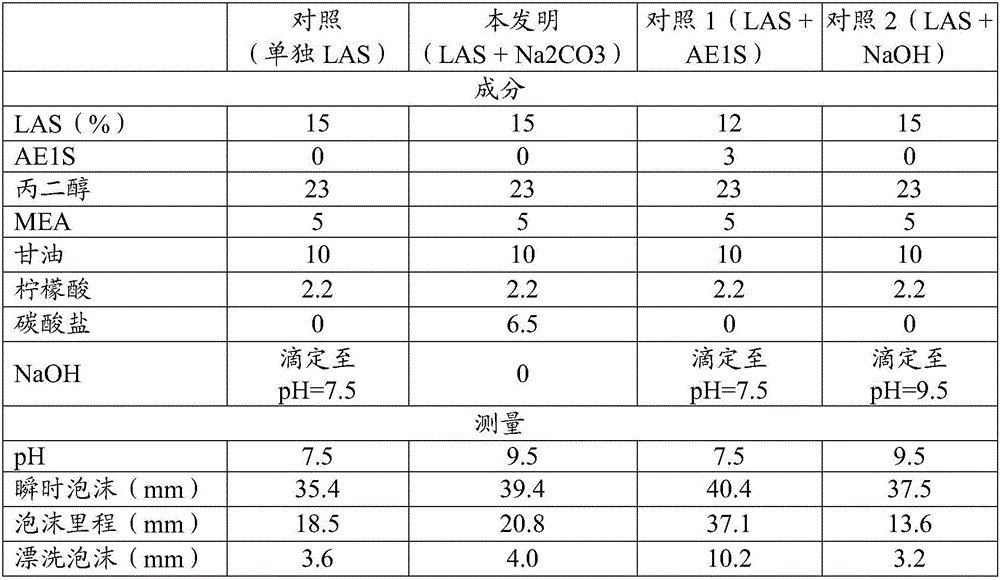

[0102] Embodiment 2: comparative test of foaming characteristics

[0103] Liquid laundry detergent compositions were prepared using a common alkaline formulation comprising about 23% by weight 1,2-propanediol, about 10% by weight glycerin, about 2.2% by weight citric acid, and about 5% by weight monoethanolamine (MEA) of four (4) test samples. The first test sample was a control sample, which contained only LAS, no AES or carbonate, and had a relatively low pH of about 7.5. The second sample is an inventive sample, which contains LAS and sodium carbonate, and has a relatively high pH of about 9.5. The third sample is Comparative Example 1, which comprises LAS and AES without sodium carbonate, and is characterized by a relatively low pH of about 7.5. The fourth sample was Comparative Example 2, which contained LAS without AES or sodium carbonate, but adjusted to a relatively high pH of about 9.5 with NaOH.

[0104] The detailed composition of these 4 test samples and their...

Embodiment 3

[0107] Embodiment 3: comparative test of phase stability

[0108] Prepare three (3) liquid laundry detergent compositions with the following ingredients, and test their corresponding phase stability according to the test method described above, and provide the test results hereinafter:

[0109] Table II :

[0110]

[0111]

[0112] The phase stability results show that when LAS and sodium carbonate are formulated into a liquid composition containing too little or too much propylene glycol and glycerin, the liquid composition is unstable and will undergo phase separation when the temperature changes. However, when the liquid composition contains suitable amounts of propylene glycol and glycerol as described in the present invention, the phase stability

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| solubility coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com