Magnetic conductive ceramic pot and preparation process thereof

A preparation process and a technology of ceramic pots, which are applied to the special materials of cooking utensils, the structure of cooking utensils, cooking utensils, etc., can solve the problems of low ceramic yield, large gap between thermal expansion and cold contraction, complex process, etc., and achieve low cost, Avoid power decline and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation process of a magnetically conductive ceramic pot mainly comprises the following steps:

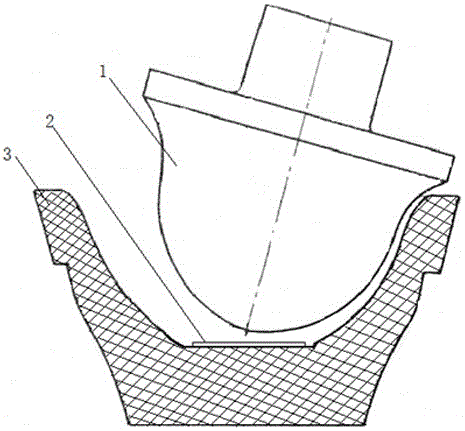

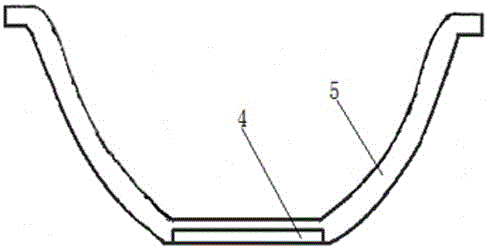

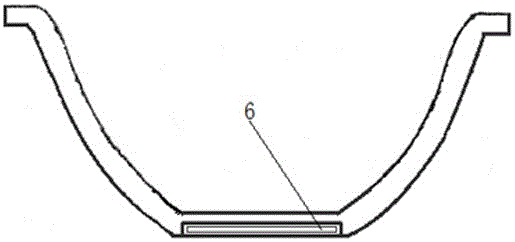

[0037] Weigh ceramic pot substrate raw materials by mass parts: 30 parts of quartz, 24 parts of kaolin, 22 parts of clay, 14 parts of potassium feldspar, 3 parts of boric acid, 4 parts of talc, 3 parts of alumina; the raw materials are prepared according to the ordinary ceramic blank preparation process Mixing ball milling → squeezing mud → refining mud to prepare ceramic blanks; then calculate the amount of ceramic blanks required according to the bottom size, shape, thickness and other parameters of a ceramic pot with a bottom diameter of 110mm; put the ceramic blanks into the ceramic pot The bottom of the gypsum model, where a boss larger than the size of the magnetic anti-oxidation heating sheet is designed in the middle of the bottom of the gypsum model, and the rolling head and the gypsum model are rolled and formed, and the ceramic blank in the model forms the bo...

Embodiment 2

[0039] A preparation process of a magnetically conductive ceramic pot mainly comprises the following steps:

[0040]Weigh ceramic pot substrate raw materials by mass: 40 parts of quartz, 20 parts of kaolin, 19 parts of clay, 12 parts of potassium feldspar, 4 parts of boric acid, 3 parts of talc, 2 parts of alumina; the raw materials are prepared according to the ordinary ceramic blank preparation process Mixing ball milling → squeezing mud → refining mud to prepare ceramic blanks; then calculate the required amount of ceramic blanks according to the bottom size, shape, thickness and other parameters of the ceramic pot 120mm; put the ceramic blanks into the plaster model used to prepare ceramic pots The bottom of the plaster model is designed with a boss larger than the size of the magnetic anti-oxidation heating sheet in the middle of the bottom of the plaster model. The rolling head and the plaster model are used to roll and form. The ceramic blank in the model forms a groove ...

Embodiment 3

[0042] A preparation process of a magnetically conductive ceramic pot mainly comprises the following steps:

[0043] Weigh the raw materials of the ceramic pot base in parts by mass: 45 parts of quartz, 20 parts of kaolin, 18 parts of clay, 10 parts of potassium feldspar, 3 parts of boric acid, 2 parts of talc, and 2 parts of alumina; the raw materials are prepared according to the ordinary ceramic blank preparation process Mixing ball milling → squeezing mud → refining mud to prepare ceramic blanks; then calculate the required amount of ceramic blanks according to the bottom size, shape, thickness and other parameters of the ceramic pot 125mm; put the ceramic blanks into the plaster model used to prepare ceramic pots The bottom of the plaster model is designed with a boss larger than the size of the magnetic anti-oxidation heating sheet in the middle of the bottom of the plaster model. The rolling head and the plaster model are used to roll and form. The ceramic blank in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com