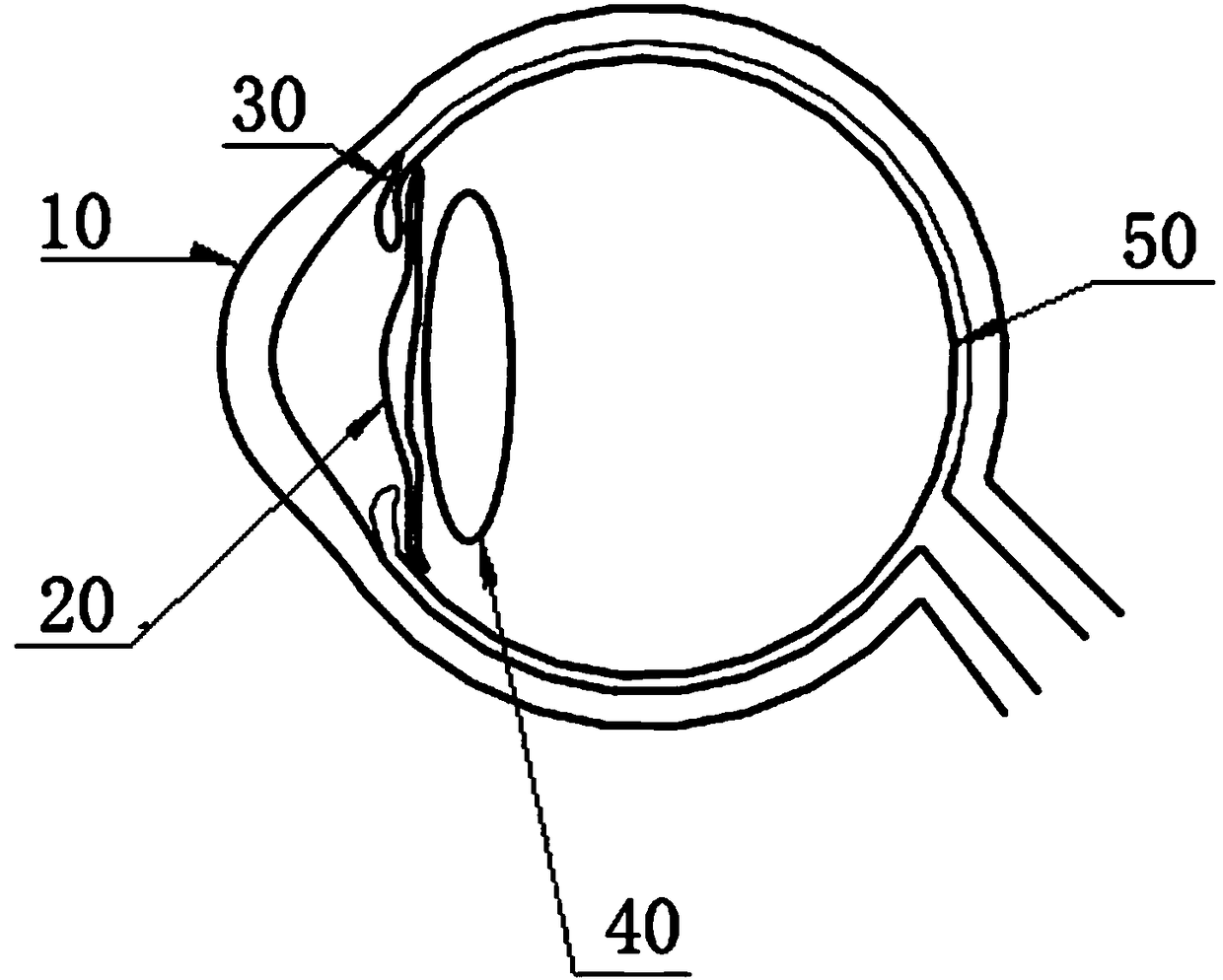

Corneal Graft Cascading Method for Improving the Diopter of Tissue-Engineered Artificial Cornea

A technology of artificial cornea and tissue engineering, which is applied in tissue regeneration, pharmaceutical formulation, additive processing, etc., and can solve the problems of insufficient refractive power of artificial cornea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

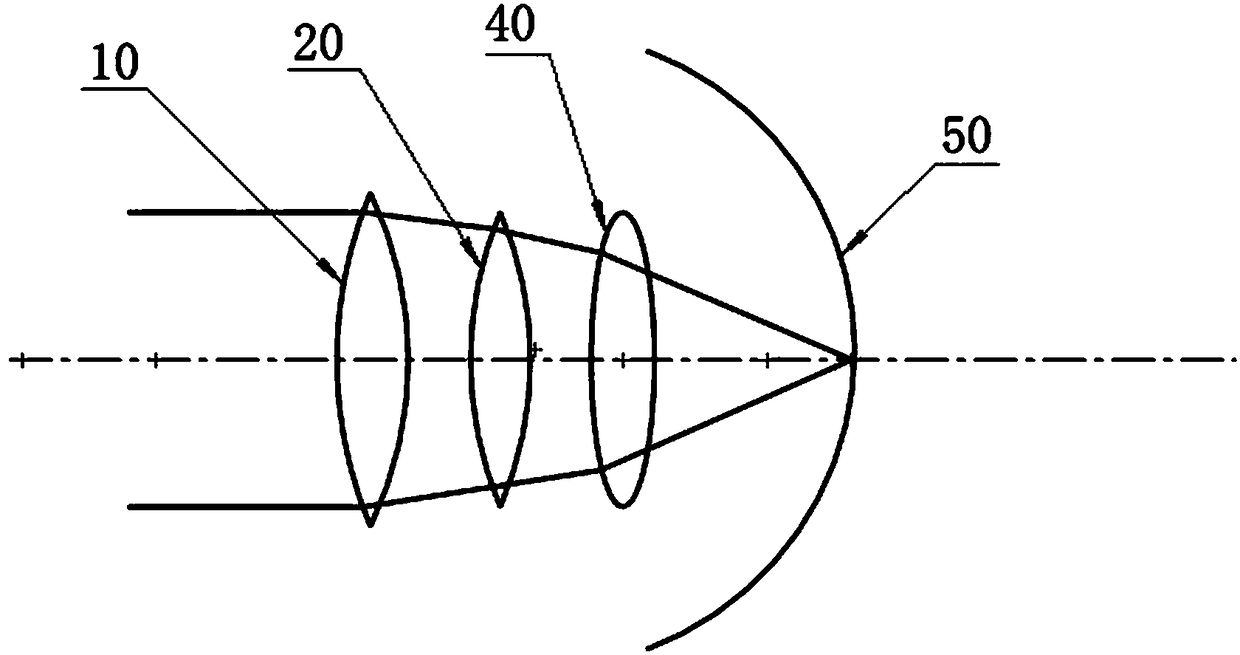

Method used

Image

Examples

preparation example Construction

[0028] 1. The preparation method of the front end corneal graft is:

[0029] 1) Preparation of three-dimensional corneal stents using multi-component copolymers as raw materials: using a 3D bioprinter, place the multi-component copolymers in the barrel of the printer, one printing requires 8-12g of raw materials, and extrude the multi-component copolymer materials according to the preset model On a printing platform loaded with a sterilized glass bottom plate, a three-dimensional scaffold in the shape of the cornea was printed.

[0030] With reference to the average parameters of the human corneal structure, the design parameters of the three-dimensional corneal graft stent in this embodiment are as follows: the curvature radius of the outer wall of the three-dimensional stent is 7.7 mm, the curvature radius of the inner wall is 6.7 mm, and the wall thickness is 200-400 μm. The diameter of the corneal graft is 12mm.

[0031] The diameter of the print head is 200μm, the extrus...

Embodiment 1

[0053] Prepare the anterior corneal graft as follows:

[0054] (1) Synthesis of ternary copolymer materials: Take 40% of ε-caprolactone monomer, 40% of lactide monomer and 20% of collagen monomer as raw materials in the reaction equipment according to the mass percentage, and add all Put in 0.5% zinc octoate as a catalyst, vacuumize, fill with nitrogen, and react in a closed polymerization equipment at 160°C for 24 hours to obtain a multi-component copolymer with a molecular weight of 32838.

[0055] (2) Print three-dimensional corneal scaffolds: using the above-mentioned ternary copolymer materials as raw materials, use a 3D bioprinter to construct a three-dimensional structure in the shape of a human cornea. The radius of curvature of the inner wall is 6.7 mm, the wall thickness is 300 μm, and the diameter is 12 mm. A three-dimensional corneal scaffold capable of loading cells is obtained. The diameter of the print head is 200 μm, the extrusion speed is 0.033 mm / s, the prin...

Embodiment 2

[0063] Prepare the posterior corneal graft in the following steps, the steps are:

[0064] 1. Carry out an eye examination on the patient, collect eye data, and calculate the degree of correction of the posterior corneal graft.

[0065] The simplified formula for calculating the corneal curvature that needs to be selected is as follows:

[0066] (horizontal curvature + vertical curvature) / 2*110% = corneal curvature to be selected

[0067] For example: the horizontal curvature is 7.8, the vertical curvature is 7.5, the base arc of the required lens is: (7.8+7.5) / 2*110%=8.4

[0068] 2. 3D printing posterior corneal graft.

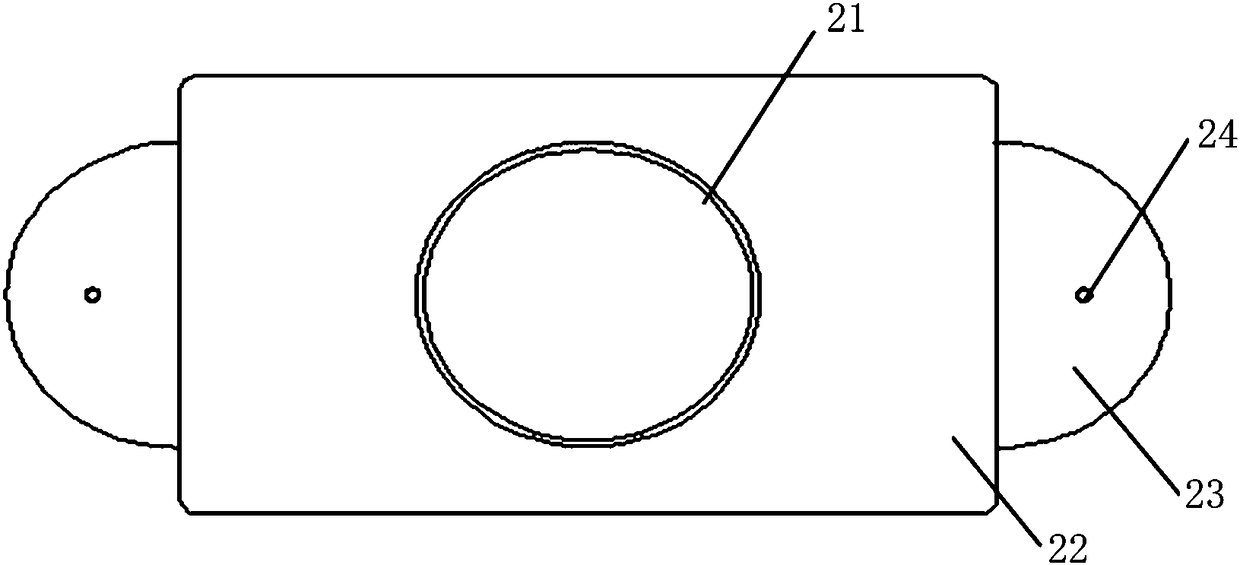

[0069] 1) Establish a three-dimensional model of the posterior corneal graft. Both the front and rear walls of the optical part use convex lenses. The diopter of the glasses is adjusted to the three-dimensional model according to the patient's needs, and then the model files are processed in layers. Posterior corneal grafts can be designed as image 3 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com