Composite material repairing and strengthening method for boss fillet weld

A composite material and composite material fiber technology, which is applied in the field of composite material repair and reinforcement where the boss welding forms a cross weld with the main pipe weld, and can solve problems such as boss fillet weld welding and pipeline girth weld welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

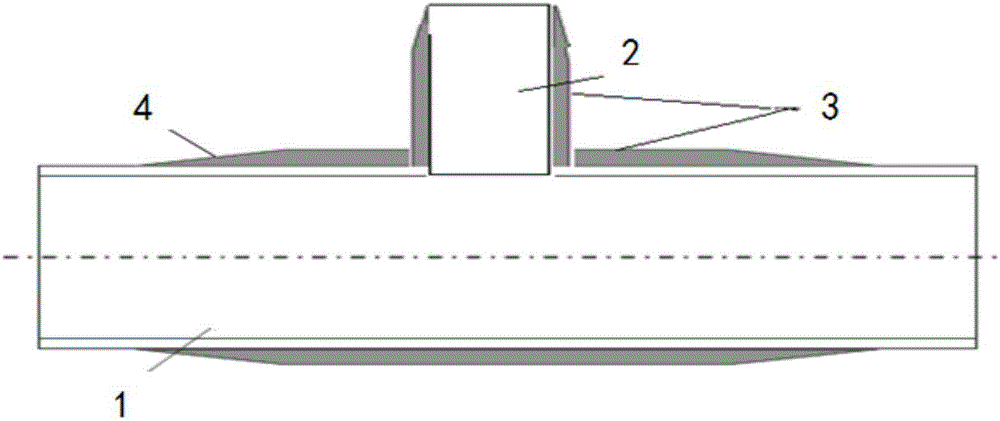

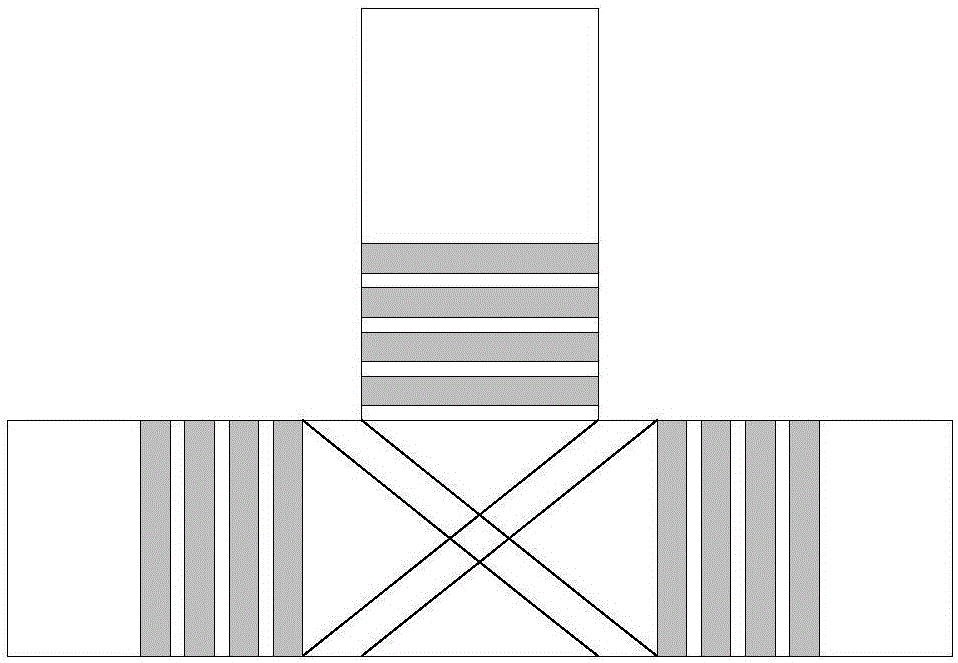

[0029] The design content of the present invention is mainly to provide a method for repairing and reinforcing composite materials of boss fillet welds, comprising the following steps:

[0030] 1) First, use a cleaning agent to clean the surface of the main pipe section, branch pipe section and fillet welded steel pipe within the width of the reinforcement to be repaired, and dry them sufficiently.

[0031] 2) Spread the prepared epoxy resin dipping glue evenly on the surface of the reinforced pipe section to be repaired.

[0032] 3) According to the minimum repair width of reinforcement, the number of reinforcement layers and the groove requirements of the boundary, the fiber cloth width is gradually reduced and the thickness of the reinforcement layer is gradually increased in the repair an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com