A low-voltage shore power cable lifting and conveying device

A technology for conveying devices and cables, applied in hoisting devices, cable laying equipment, etc., can solve problems such as waste of resources, heavy manual work, difficult transfer, etc., and achieve the goals of saving renovation costs, eliminating potential safety hazards, and improving operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

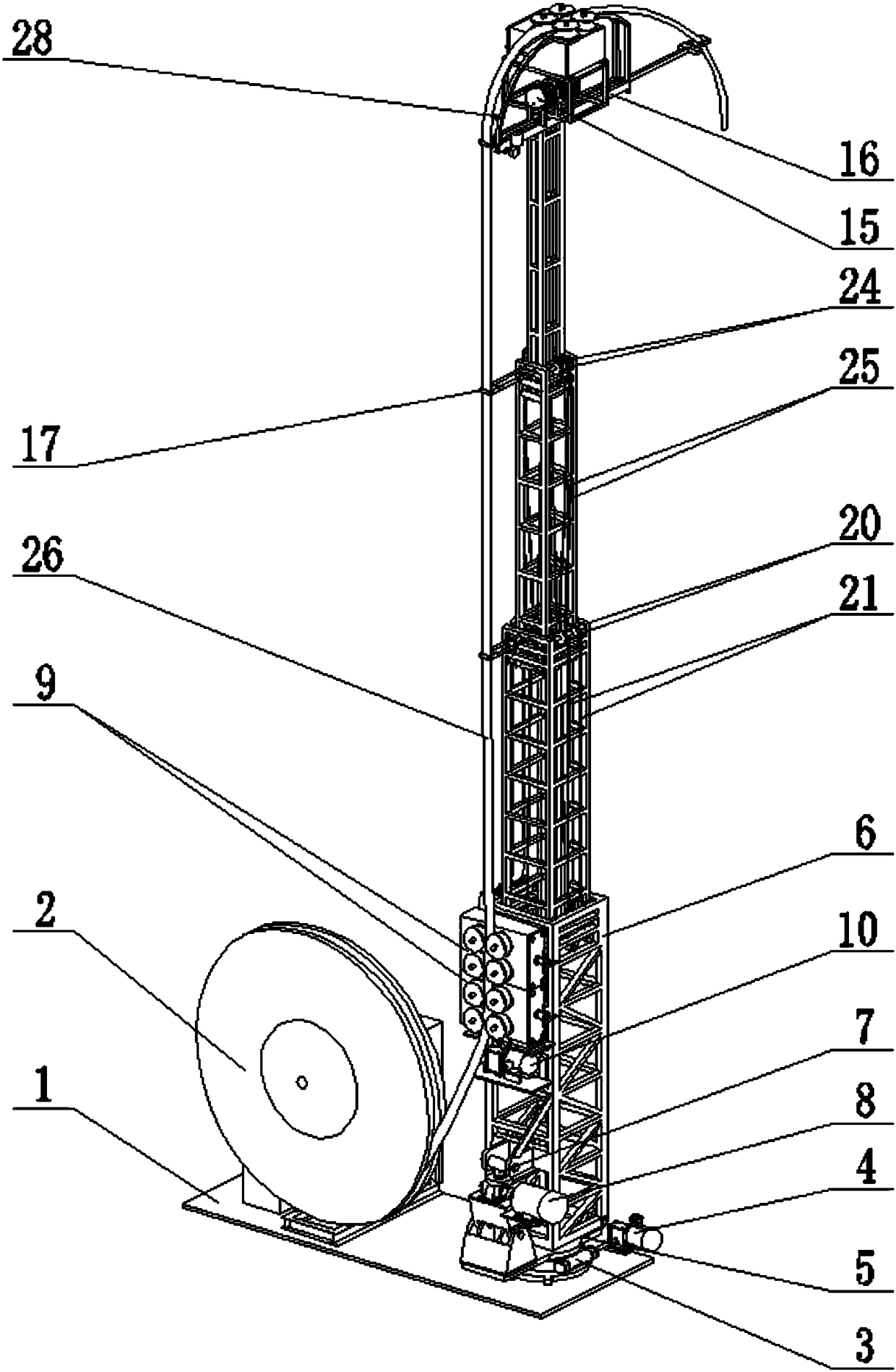

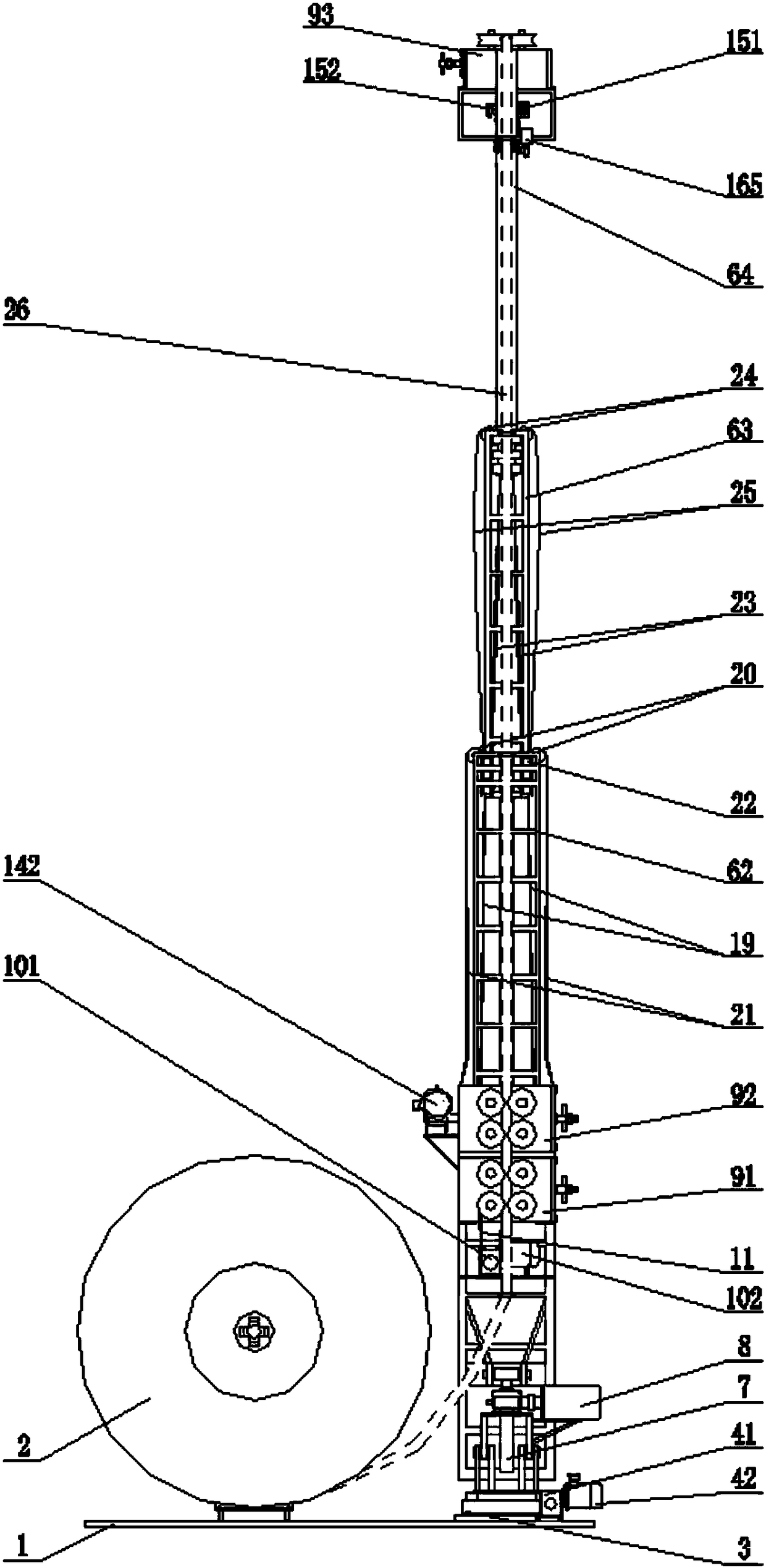

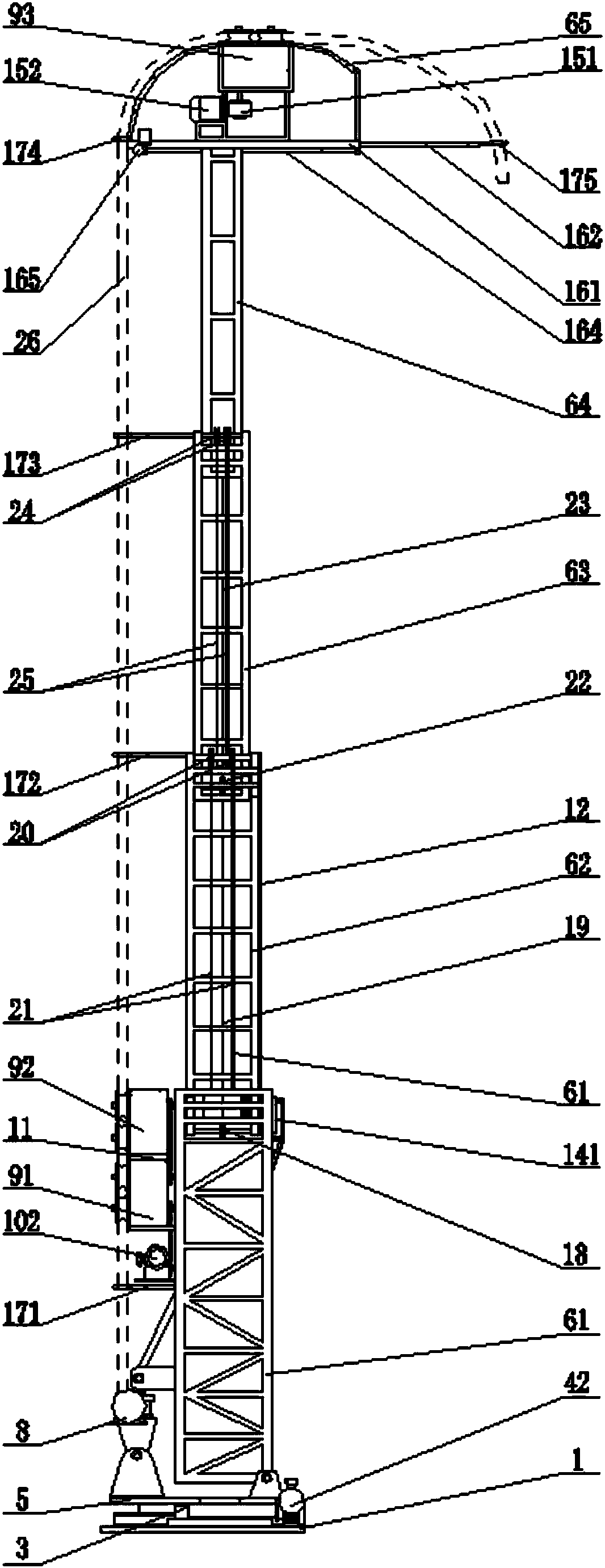

[0023] Below in conjunction with accompanying drawing, describe the specific embodiment of the patent of the present invention in detail.

[0024] The low-voltage shore power cable lifting and conveying device of this embodiment is as follows: Figure 1-6 As shown, a cable reel 2 is fixed on one side of the upper surface of the mounting seat 1, a rotating device 3 is fixed on the other side of the upper surface of the mounting seat 1, and a rotating power mechanism 4 is fixed on the side of the rotating device 3, including a worm gear reducer. 41 and motor 42, the rotating device 3 is fixedly provided with a rotating platform 5, and the upper surface of the rotating platform 5 is hinged with a lifting tower 6 near the side of the ship.

[0025]Lifting tower 6 comprises first level lifting tower frame 61, second level lifting tower frame 62, third level lifting tower frame 63, fourth level lifting tower frame 64, fifth level lifting tower frame 65, first level lifting tower fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com