A kind of high thermal conductivity polyimide/boron nitride composite material and preparation method thereof

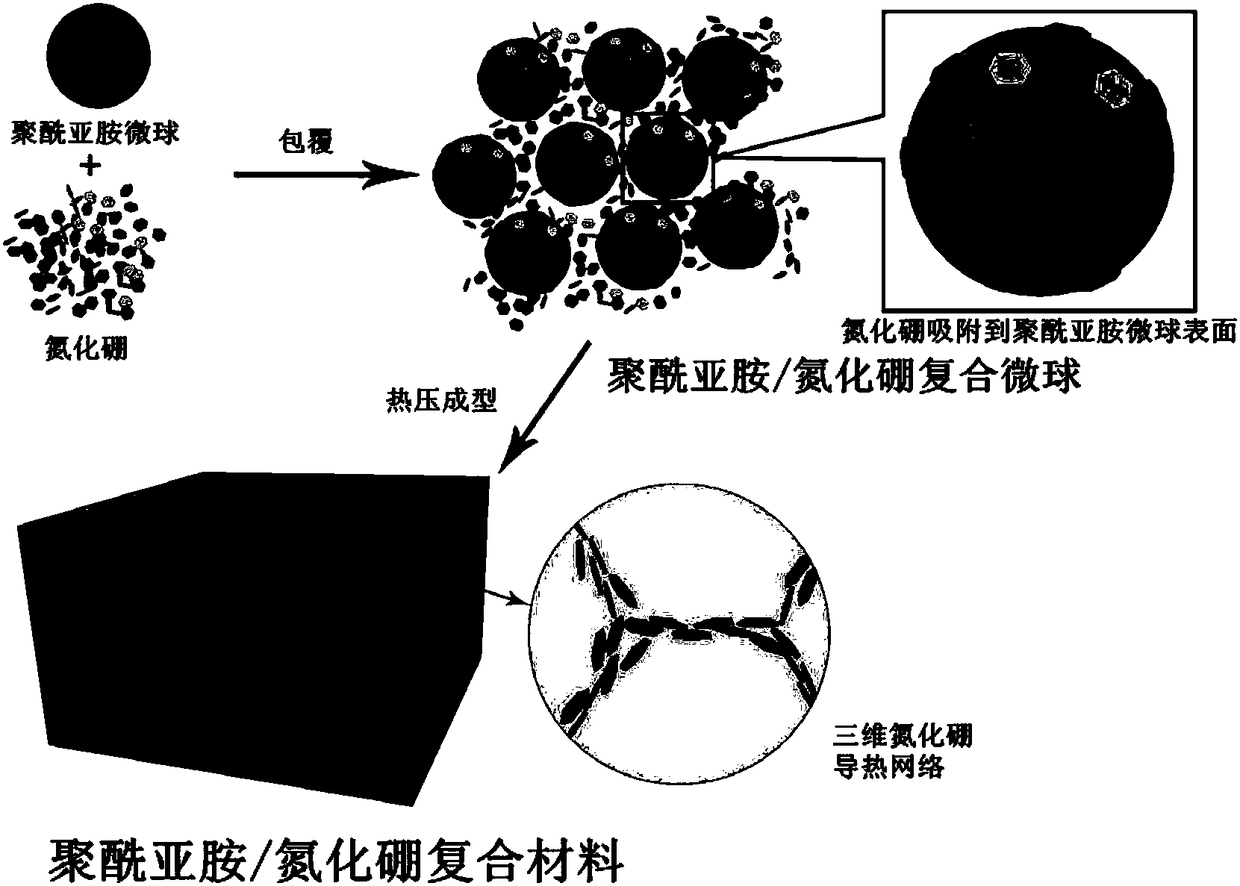

A technology of polyimide and composite materials, which is applied in the field of high thermal conductivity polyimide/boron nitride composite materials and its preparation, which can solve the problem of limited improvement of thermal conductivity of composite materials, inability to form thermal conductivity networks, and chemical modification effects Poor problems, to achieve the effect of being suitable for industrial production, simple and practical molding method, and avoiding the influence of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Add 0.54g of self-made polyimide microspheres to 54g of water, stir and disperse evenly to obtain a dispersion of polyimide microspheres; add 0.06g of boron nitride to 6g of water, and ultrasonically disperse for 1 hour to obtain nitrided boron dispersion.

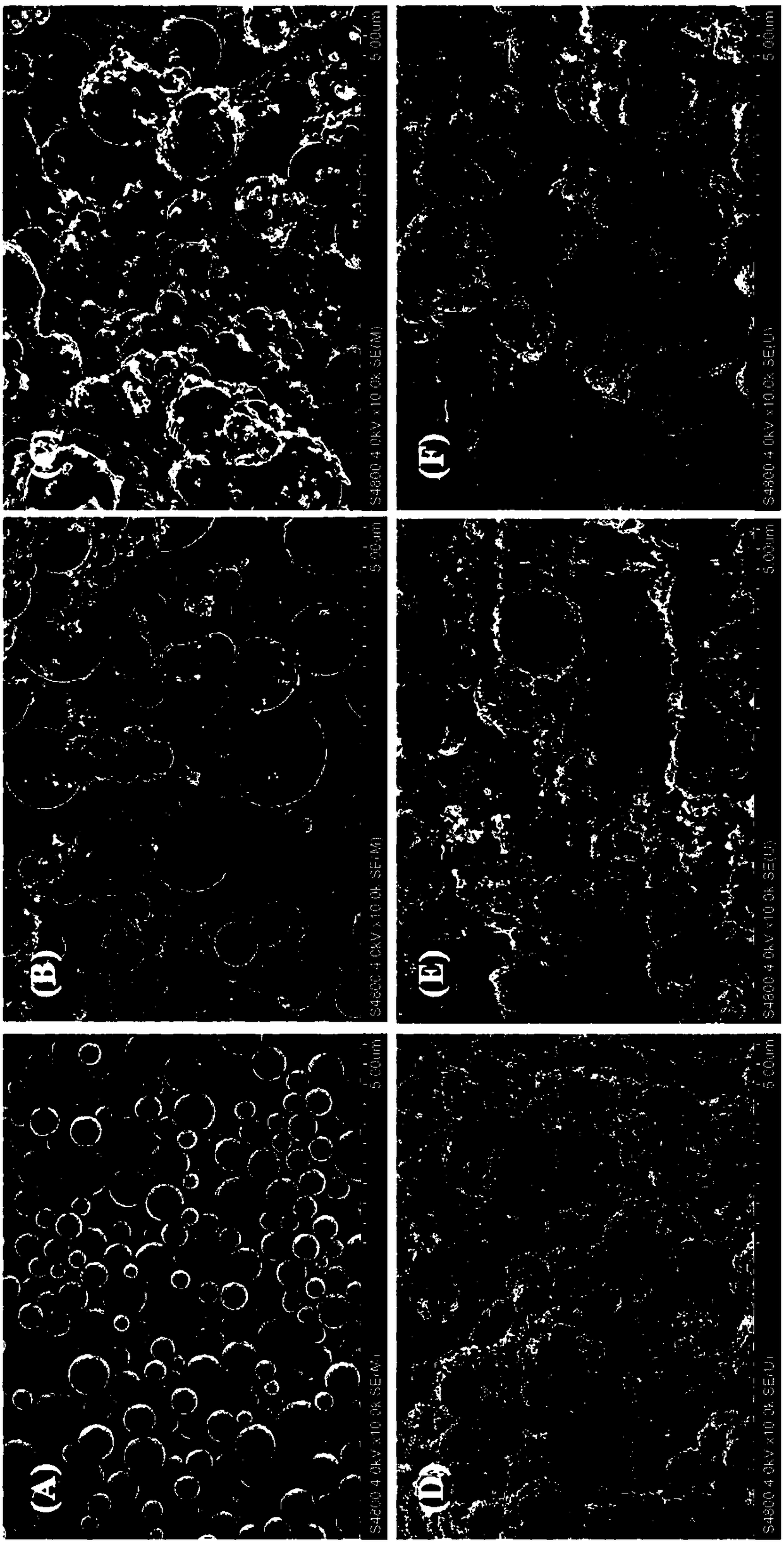

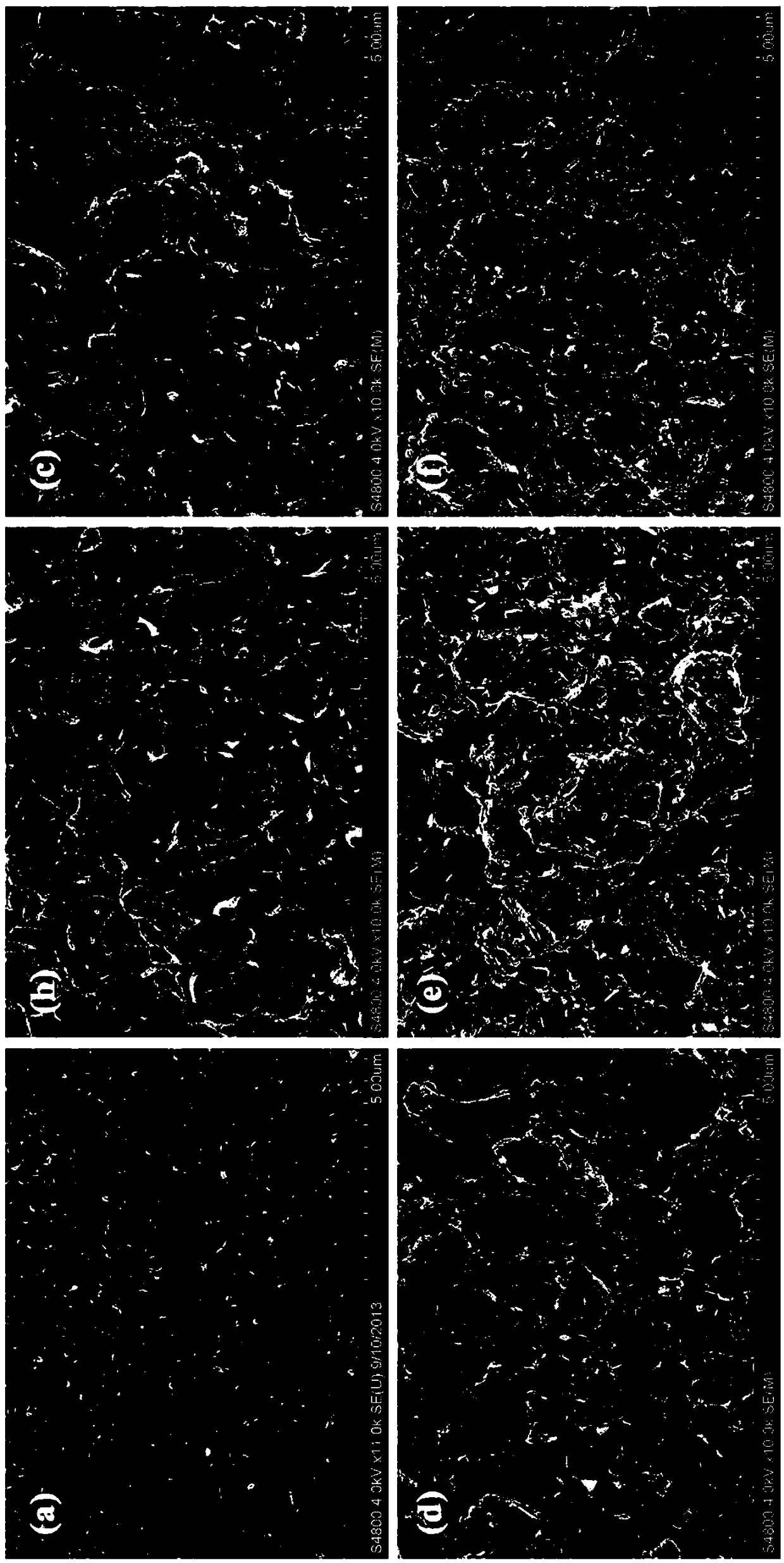

[0061] (2) Slowly add the boron nitride dispersion into the polyimide microsphere dispersion, and stir for 1 h at 25°C to obtain polyimide / boron nitride composite microspheres, and the scanning electron microscope image of the resulting composite microspheres Such as figure 2 (B) shown.

[0062] (3) Put the polyimide / boron nitride composite microspheres in the mold, hold the pressure at 230°C and 1000MPa pressure for 1h, and obtain a polyimide / boron nitride composite material with a thickness of about 1mm, which is composed of The mass percentage is composed of 90% polyimide microspheres and 10% boron nitride, and the scanning electron microscope picture of the cross section of the composite material is as fo...

Embodiment 2

[0067] (1) Add 0.48g of self-made polyimide microspheres to 48g of water, stir and disperse evenly to obtain a dispersion of polyimide microspheres; add 0.12g of boron nitride to 12g of water, and ultrasonically disperse for 1 hour to obtain a nitrided boron dispersion.

[0068] (2) Slowly add the boron nitride dispersion into the polyimide microsphere dispersion, and stir for 3 hours at 25°C to obtain polyimide / boron nitride composite microspheres, and the scanning electron microscope image of the resulting composite microspheres Such as figure 2 (C) shown.

[0069] (3) Put the polyimide / boron nitride composite microspheres in the mold, hold the pressure at 230°C and 1000MPa pressure for 1h, and obtain a polyimide / boron nitride composite material with a thickness of about 1mm, which is composed of The mass percentage is 80% polyimide microspheres and 20% boron nitride composition, and the scanning electron microscope picture of the composite material section of gained is a...

Embodiment 3

[0072] (1) Add 0.42g of self-made polyimide microspheres to 42g of water, stir and disperse evenly to obtain a dispersion of polyimide microspheres; add 0.18g of boron nitride to 18g of water, and ultrasonically disperse for 1 hour to obtain a nitrided boron dispersion.

[0073] (2) Slowly add the boron nitride dispersion into the polyimide microsphere dispersion, and stir at 25°C for 0.5h to obtain polyimide / boron nitride composite microspheres, and the scanning electron microscope of the obtained composite microspheres Figure such as figure 2 (D) shown.

[0074] (3) Put the polyimide / boron nitride composite microspheres in the mold, hold the pressure at 230°C and 1000MPa pressure for 1h, and obtain a polyimide / boron nitride composite material with a thickness of about 1mm, which is composed of The mass percent is 70% polyimide microspheres and 30% boron nitride composition, and the scanning electron microscope picture of the cross-section of the composite material is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com