A kind of high-conductivity polyimide-graphene composite material and preparation method thereof

A technology of polyimide and high conductivity, which is applied in the field of high conductivity polyimide-graphene composite material and its preparation, can solve the problems of difficult dispersion of graphene, cumbersome process, high percolation threshold, etc. Achieve the effects of simple and practical molding method, simplified process and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

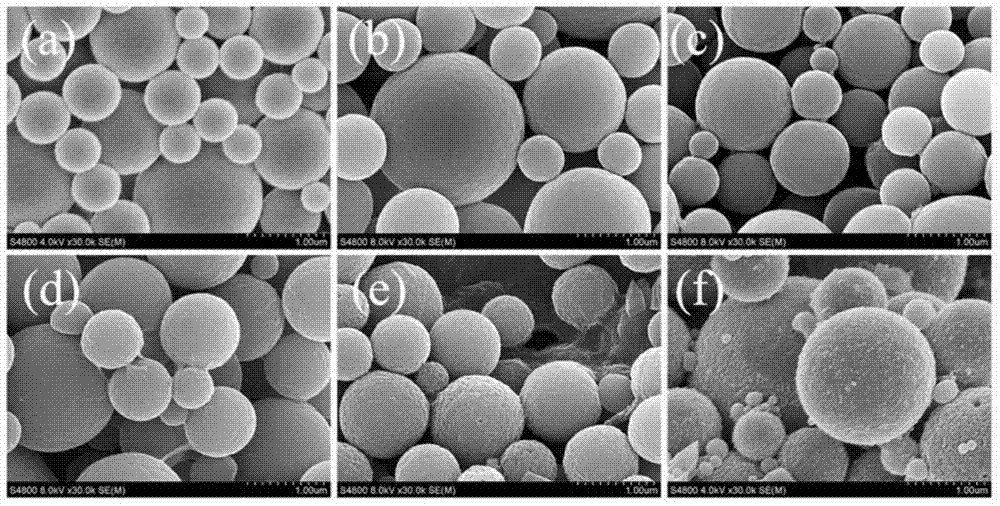

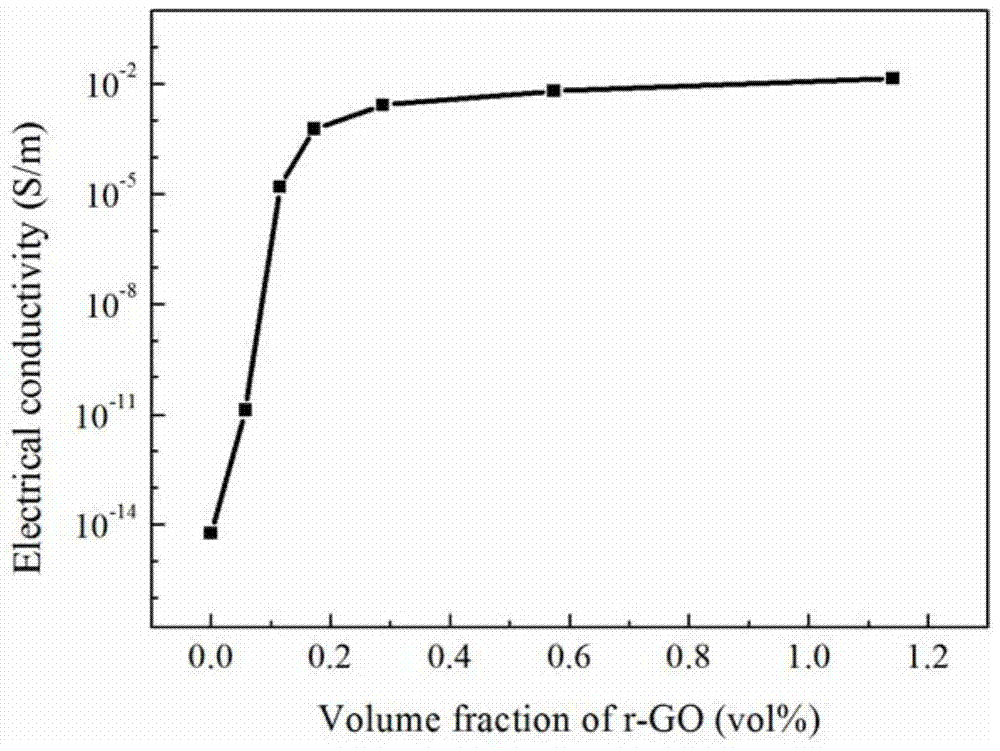

[0040]Add 0.6 g of self-made polyimide microspheres into a 100 ml single-necked flask, add 54 g of deionized water, stir and disperse evenly, and obtain a dispersion of polyimide microspheres. Add 0.6 mg of self-made graphene oxide (for specific preparation method, see: Journal of the American Chemical Society 1958; 80:1339) into 6 g of deionized water, and ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion. Then the graphene oxide dispersion was slowly added to the polyimide microsphere dispersion, and stirred at 25° C. for 1 h to obtain a graphene oxide-coated polyimide microsphere dispersion. Next, 0.02 g of hydrazine hydrate was added to the solution, and the reaction solution was heated to 90° C. for 24 hours of reaction. Centrifuged and washed 3 times to obtain polyimide microspheres coated with reduced graphene oxide.

[0041] Wherein, the preparation method of polyimide microsphere is as follows:

[0042] (1) Add polyimide to N,N-dimethylacetami...

Embodiment 2

[0050] Add 0.6 g of self-made polyimide microspheres into a 100 ml single-necked flask, add 48 g of deionized water, stir and disperse evenly, and obtain a dispersion of polyimide microspheres. Add 1.2 mg of self-made graphene oxide into 6 g of deionized water, and ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion. Then the graphene oxide dispersion was slowly added to the polyimide microsphere dispersion, and stirred at 25° C. for 1 h to obtain a graphene oxide-coated polyimide microsphere dispersion. Next, 0.04 g of hydrazine hydrate was added to the solution, and the reaction solution was heated to 90° C. for 24 hours of reaction. Centrifuged and washed 3 times to obtain polyimide microspheres coated with reduced graphene oxide.

[0051] Scanning electron microscopy showed that the surface of the microspheres was slightly coated with a layer of graphene, and the intensity of the PI characteristic peak on the Raman spectrum peak was weakened.

[0052...

Embodiment 3

[0054] Add 0.6 g of self-made polyimide microspheres into a 100 ml single-necked flask, add 42 g of deionized water, stir and disperse evenly, and obtain a dispersion of polyimide microspheres. Add 1.8 mg of self-made graphene oxide into 18 g of deionized water, and ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion. Then the graphene oxide dispersion was slowly added to the polyimide microsphere dispersion, and stirred at 25° C. for 1 h to obtain a graphene oxide-coated polyimide microsphere dispersion. Next, 0.05 g of hydrazine hydrate was added to the solution, and the reaction solution was heated to 90° C. for 24 hours of reaction. Centrifuged and washed 3 times to obtain polyimide microspheres coated with reduced graphene oxide.

[0055] Scanning electron microscopy showed that the surface of the microspheres was slightly coated with a layer of graphene, and the intensity of the PI characteristic peak on the Raman spectrum peak was weakened.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com