Styrene-acrylic resin for toner and preparation method thereof

A technology for styrene-acrylic resin and toner, applied in the field of styrene-acrylic resin for toner and its preparation, can solve the problems of inability to effectively control polymer properties, uncontrollable molecular weight of polymer resin, high solvent recovery cost, and achieve low odor, The effect of low water absorption and short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of above-mentioned styrene-acrylic resin for toner comprises the following steps:

[0059] 1) Mix and stir 0.5-2 parts of emulsifier and 20-50 parts of water evenly, then add 0-5 parts of pH regulator, 5-15 parts of hard monomer and 1-5 parts of soft monomer, stir well to obtain seeds pre-emulsion;

[0060] 2) Mix and stir 1-4 parts of emulsifier and 40-120 parts of water evenly, then add 55-90 parts of hard monomer, 1-20 parts of soft monomer, 0.5-10 parts of functional monomer and 0.1-2 parts Chain transfer agent, stir evenly to obtain pre-emulsion;

[0061] 3) Mix and stir 0.2-0.5 parts of initiator and 5-15 parts of water evenly, then add it to the seed pre-emulsion in step 1), fully react to obtain the seed emulsion;

[0062] 4) Add the pre-emulsion in step 2) to the seed emulsion in step 3), add 0.2-0.5 parts of initiator and 10-20 parts of water, and fully react to obtain a styrene-acrylic emulsion;

[0063] 5) The styrene-acrylic emulsi...

Embodiment 1

[0068] A raw material composition of styrene-acrylic resin for toner is as follows (parts by mass):

[0069] Styrene: 95 parts;

[0070] Butyl acrylate: 15 parts;

[0071] Isooctyl acrylate: 5 parts;

[0072] Methacrylic acid: 0.5 parts;

[0073] Dodecyl mercaptan: 0.8 parts;

[0074]Allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate: 3 parts;

[0075] Potassium persulfate: 0.7 parts;

[0076] Sodium bicarbonate: 1 part;

[0077] Water: 150 parts.

[0078] The preparation method comprises the following steps:

[0079] 1) Dissolve 1 part of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate in 30 parts of water, stir evenly to obtain an aqueous emulsifier solution, then add 1 part of sodium bicarbonate, 12 parts of styrene and 2 parts of butyl acrylate, stirred at a low speed for 30 minutes to obtain a seed pre-emulsion;

[0080] 2) Dissolve 2 parts of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfat...

Embodiment 2

[0088] A raw material composition of styrene-acrylic resin for toner is as follows (parts by mass):

[0089] Styrene: 81 parts;

[0090] Butyl acrylate: 13.5 parts;

[0091] Isooctyl acrylate: 5 parts;

[0092] Methacrylic acid: 0.5 parts;

[0093] Dodecyl mercaptan: 0.8 part;

[0094] Allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate: 2 parts;

[0095] Potassium persulfate: 0.7 parts;

[0096] Sodium bicarbonate: 2 parts;

[0097] Water: 140 parts.

[0098] The preparation method comprises the following steps:

[0099] 1) Dissolve 1 part of allyloxynonylphenol propanol polyoxyethylene (10) ether ammonium sulfate in 30 parts of water, stir evenly to obtain an aqueous emulsifier solution, then add 2 parts of sodium bicarbonate, 8 parts of styrene and 2 parts of butyl acrylate, stirred at a low speed for 30 minutes to obtain a seed pre-emulsion;

[0100] 2) Dissolve 1 part of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfa...

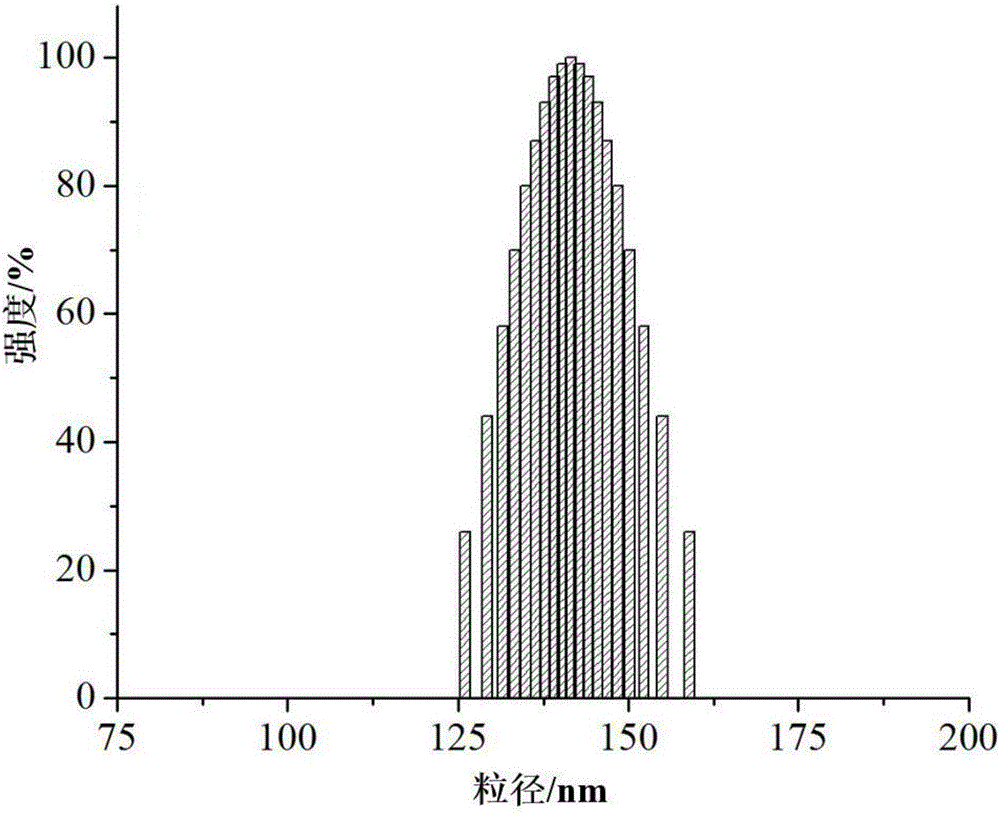

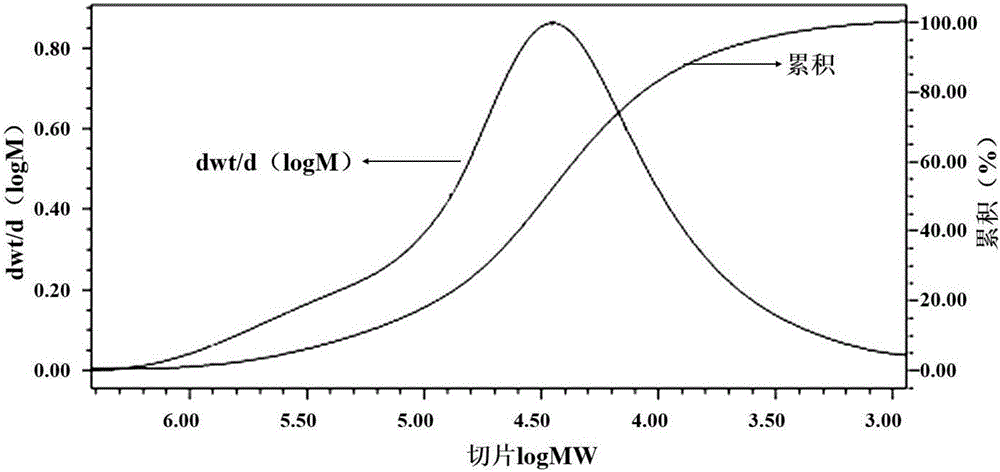

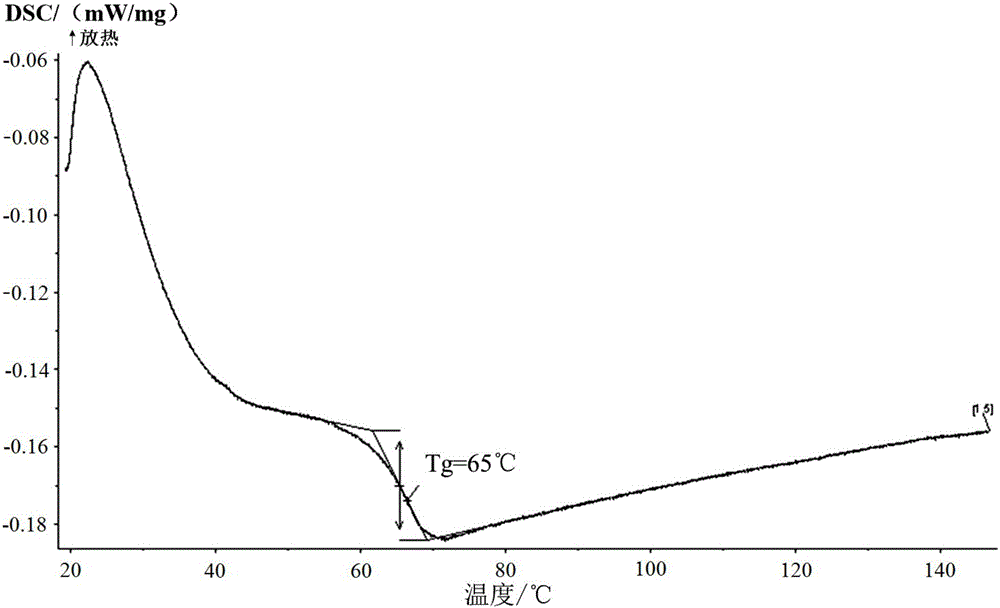

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com