Diesel oil efficiency-increase and emission-reduction additive

A kind of additive and diesel technology, applied in fuel additives, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of not improving the combustion efficiency of diesel oil, reducing the normal operation of internal combustion engines, and complicated production processes, so as to improve the cold start of fuel problems, improve storage stability, and reduce the effect of nozzle carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

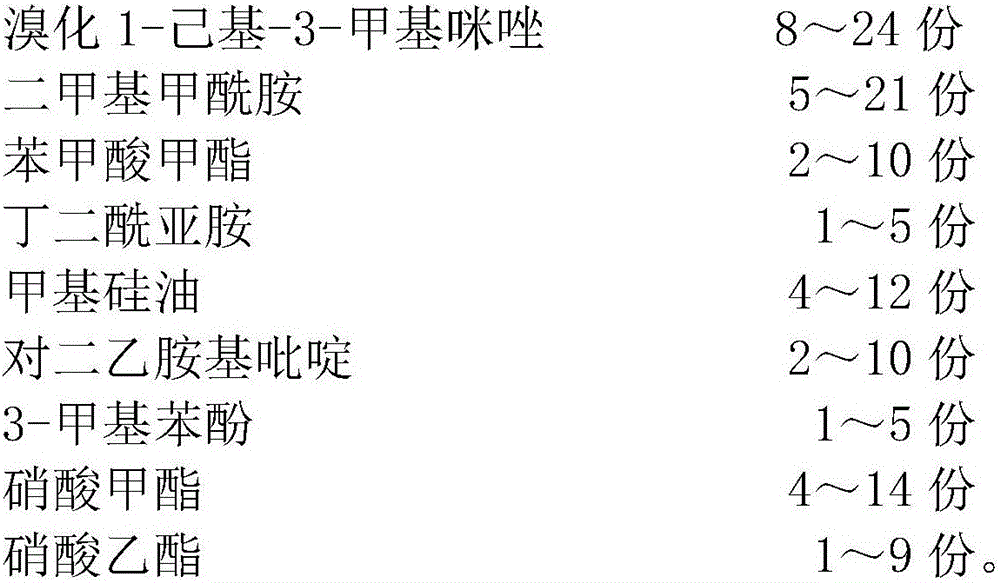

[0024] Diesel oil efficiency and emission reduction additive is made of the following raw materials in parts by weight (mixed uniformly at normal temperature):

[0025]

[0026] The application of the diesel fuel synergistic emission reduction additive of the present invention in the preparation of diesel fuel, the additive accounts for 0.02% of the mass of diesel fuel.

Embodiment 2

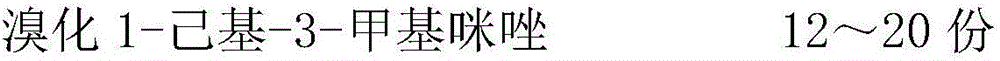

[0028] Diesel oil efficiency and emission reduction additive is made of the following raw materials in parts by weight (mixed uniformly at normal temperature):

[0029]

[0030] The application of the diesel oil synergistic emission reduction additive of the present invention in the preparation of diesel fuel, the additive accounts for 0.04% of the mass of diesel fuel.

Embodiment 3

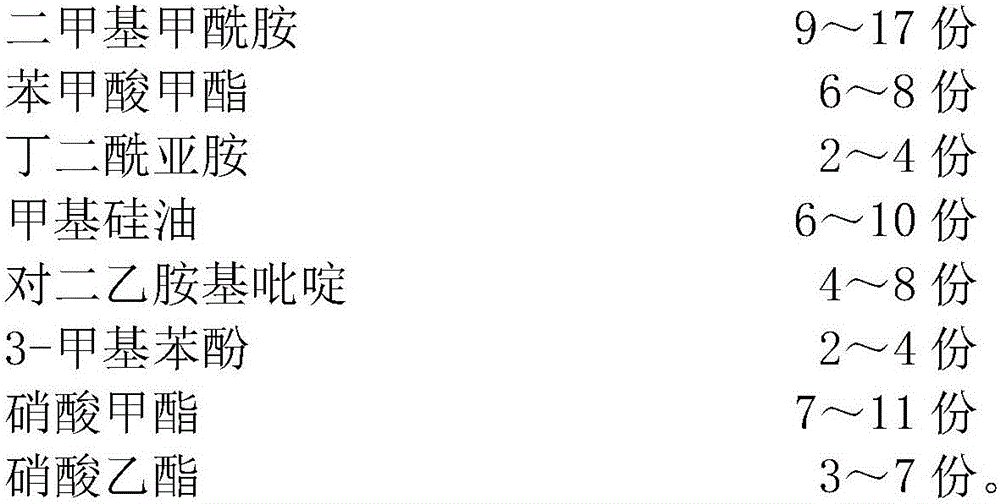

[0032] Diesel oil efficiency and emission reduction additive is made of the following raw materials in parts by weight (mixed uniformly at normal temperature):

[0033]

[0034]

[0035] The diesel oil efficiency and emission reduction additive of the present invention is used in the preparation of diesel fuel, and the additive accounts for 0.06% of the mass of diesel fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com