Tunnel surrounding rock monitoring method based on multifunctional intelligent anchor rod

A multi-functional, bolt technology, applied in the direction of bolt installation, foundation structure test, measurement force, etc., can solve the problems of inability to real-time monitoring, large random error, difficult operation, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

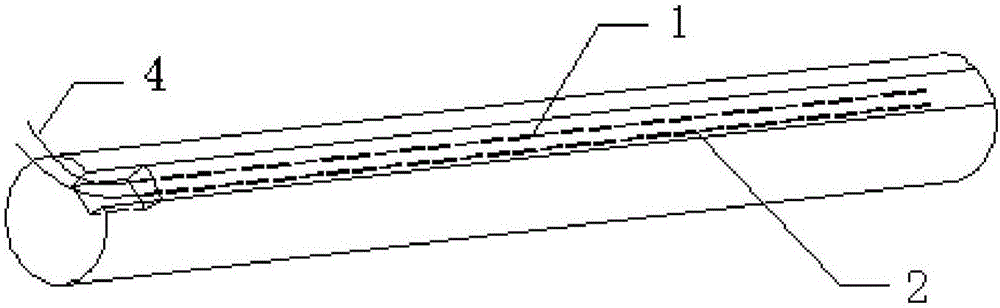

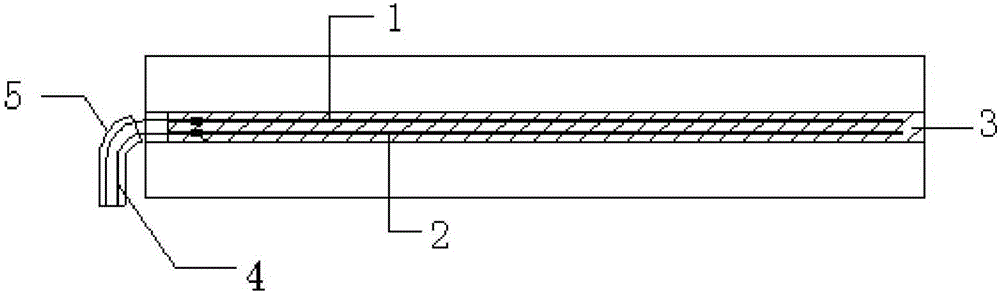

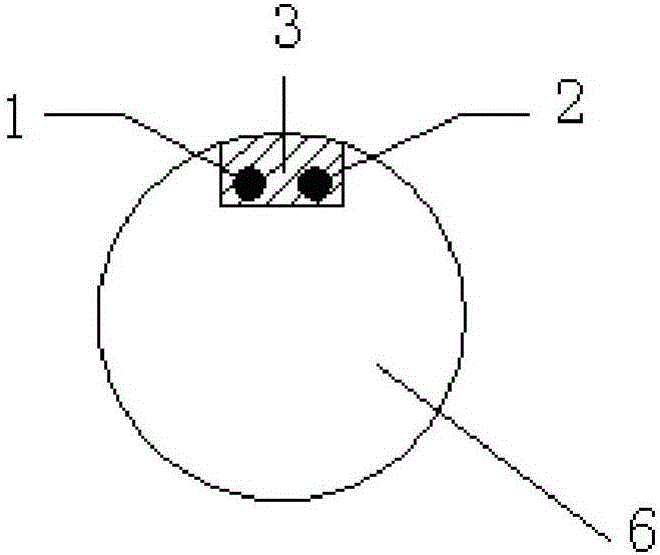

[0050] Such as Figure 1-5 As shown, a multi-functional intelligent anchor rod based on long-gauge fiber gratings, including non-fused long-gauge-length multi-grating sensors 1, fiber grating multi-point temperature compensation auxiliary sensors 2, epoxy resin or planting glue 3, armored Optical cable 4 and soft plastic casing 5;

[0051] The non-welding long gauge length multi-grating sensor 1 and the fiber grating multi-point temperature compensation auxiliary sensor 2 are installed in the small groove opened in the longitudinal direction of the anchor rod 6, and are encapsulated by epoxy resin or embedding glue 3;

[0052] The non-fusion long gauge multi-grating sensor 1 includes a plurality of long gauge fiber grating sensing units connected in series in sequence, and the long gauge fiber grating sensing unit includes a sleeve, an optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com