Method for preparing micro-nano structure on surface of base material, base material with micro-nano structure on surface and application of base material

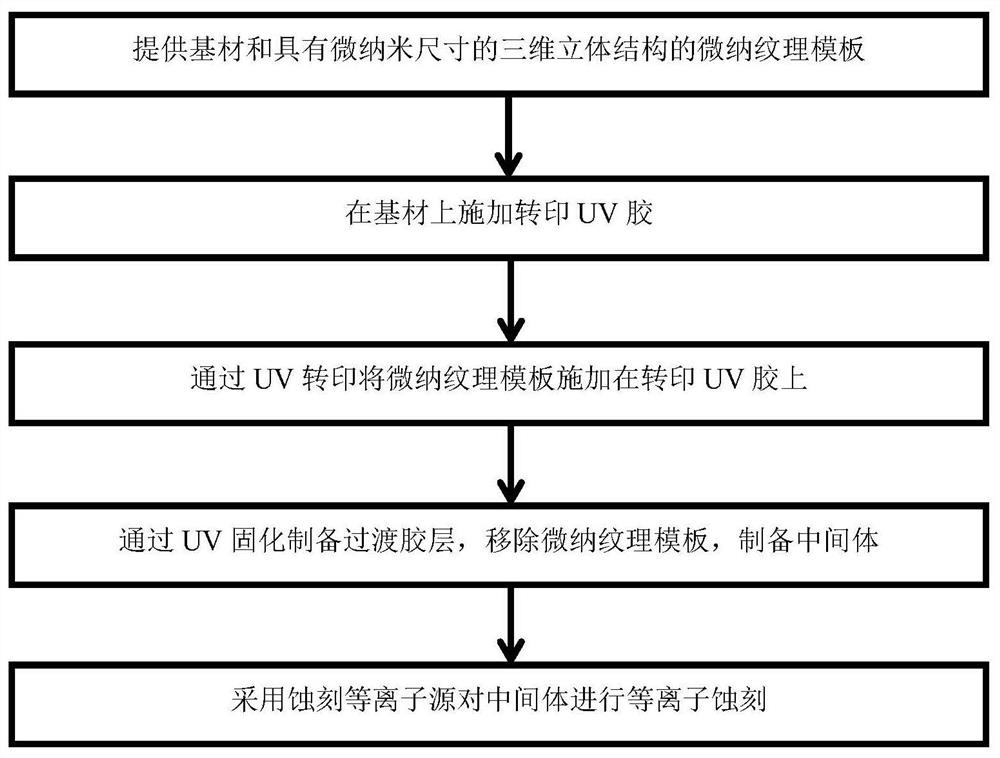

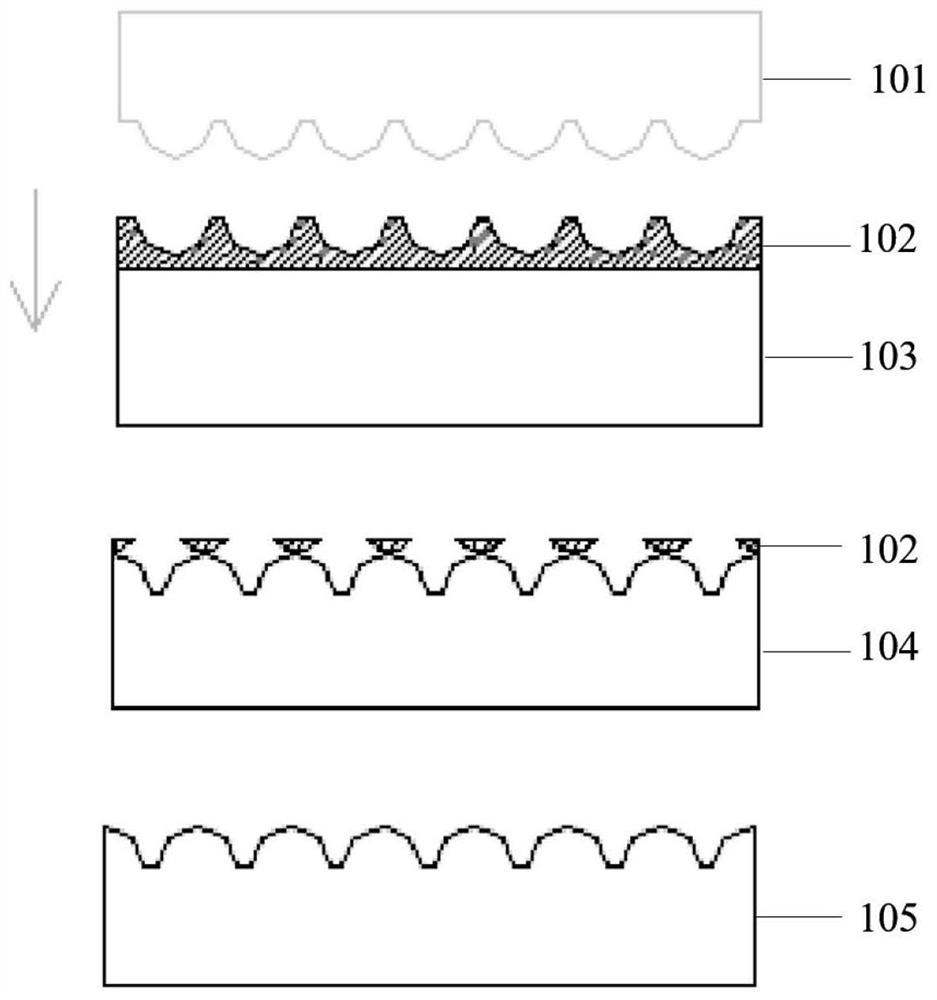

A technology of micro-nano structure and substrate surface, which is applied in the field of material surface processing, can solve the problems of complicated process and poor shape controllability, and achieve the effect of simple operation, saving production cost, and controllable micro-nano structure shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A PET film with a three-dimensional concave columnar array micro-nano texture template with a diameter of 2.5 μm and a depth of 300 nm is used as a transfer mold. The texture surface has an anti-sticking effect and does not adhere to the cured transfer UV glue.

[0081] Point the transfer UV glue line on the edge of the outer surface of the PMMA\PC composite board substrate, and then place the PET film of the transfer mold on the glue line substrate, the mold texture side faces the transfer UV glue, and the mold texture area Corresponds to the area where the substrate needs to be textured. Apply roller pressure on the outer surface of the transfer mold, and roll from one side of the dispensing line to the corresponding side, so that the transfer UV glue is completely filled between the texture surface of the transfer mold and the surface of the substrate.

[0082] Use a full-band UV surface light source with an energy of 360mJ to irradiate and transfer the UV adhesive l...

Embodiment 2

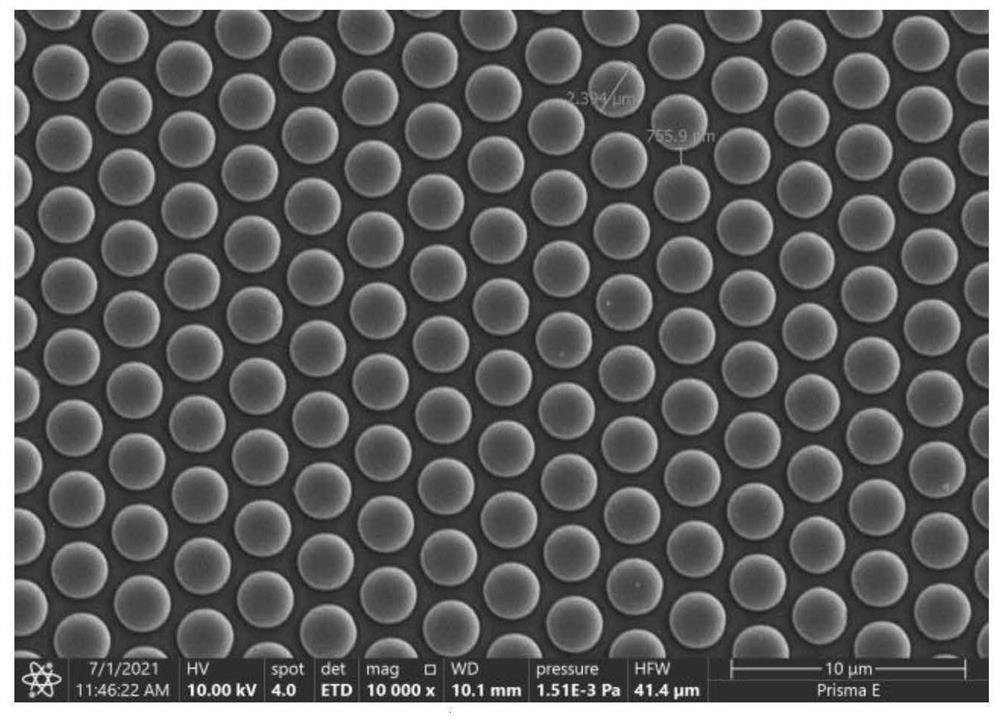

[0087] A PET film with a three-dimensional convex columnar array micro-nano texture template with a diameter of 600nm and a depth of 200nm is used as a transfer mold. The texture surface has an anti-adhesive effect and does not adhere to the cured transfer UV glue.

[0088] Point transfer UV glue line on the edge side of the outer surface of the high-alumina silica glass substrate, and then place the transfer mold PET film on the glue line substrate, the mold texture side faces the transfer UV glue, the mold texture area and The base material needs to be made corresponding to the texture area. Apply roller pressure on the outer surface of the transfer mold, and roll from one side of the dispensing line to the corresponding side, so that the transfer UV glue is completely filled between the texture surface of the transfer mold and the surface of the substrate.

[0089] Using a full-band UV surface light source with an energy of 360mJ, irradiate the UV adhesive layer for 6s, cur...

Embodiment 3

[0095] A template with surface topography of 10 μm, irregular arrangement of 1 micron depth, and dot-like topography of different sizes is used as a micro-nano texture mold. The texture surface has an anti-sticking effect and does not adhere to the cured transfer UV glue. .

[0096] On the edge of the surface of the micro-nano texture on the surface of the glass substrate, point transfer UV glue line, and then place the transfer micro-nano texture mold on the glue line substrate, the mold texture side faces the transfer UV glue, and the mold texture area Corresponds to the area where the substrate needs to be textured. Apply roller pressure on the outer surface of the transfer mold, and roll from one side of the dispensing line to the corresponding side, so that the transfer UV glue is completely filled between the texture surface of the transfer mold and the surface of the substrate.

[0097] Using a full-band UV surface light source with an energy of 800mJ, irradiate the UV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com