Method for measuring residual stress of metal microstructure

A metal microstructure and residual stress technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the internal atomic interaction, does not have vibration and rotational degrees of freedom, and cannot measure the residual stress of metal microdevices and other problems, to achieve the effect of expanding the scope of application, improving dimensional accuracy and production yield, and widening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

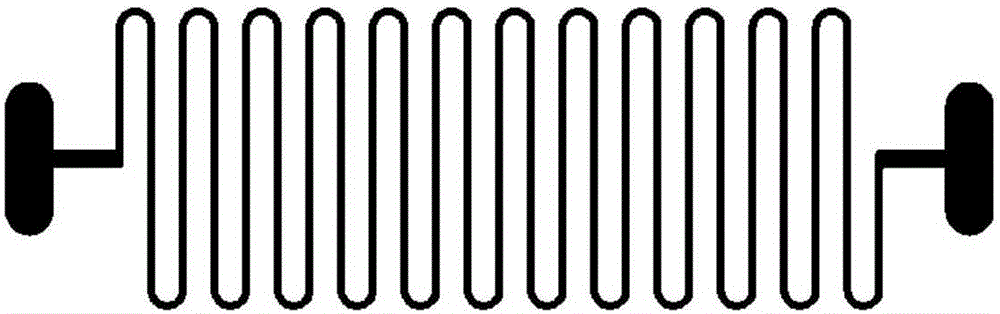

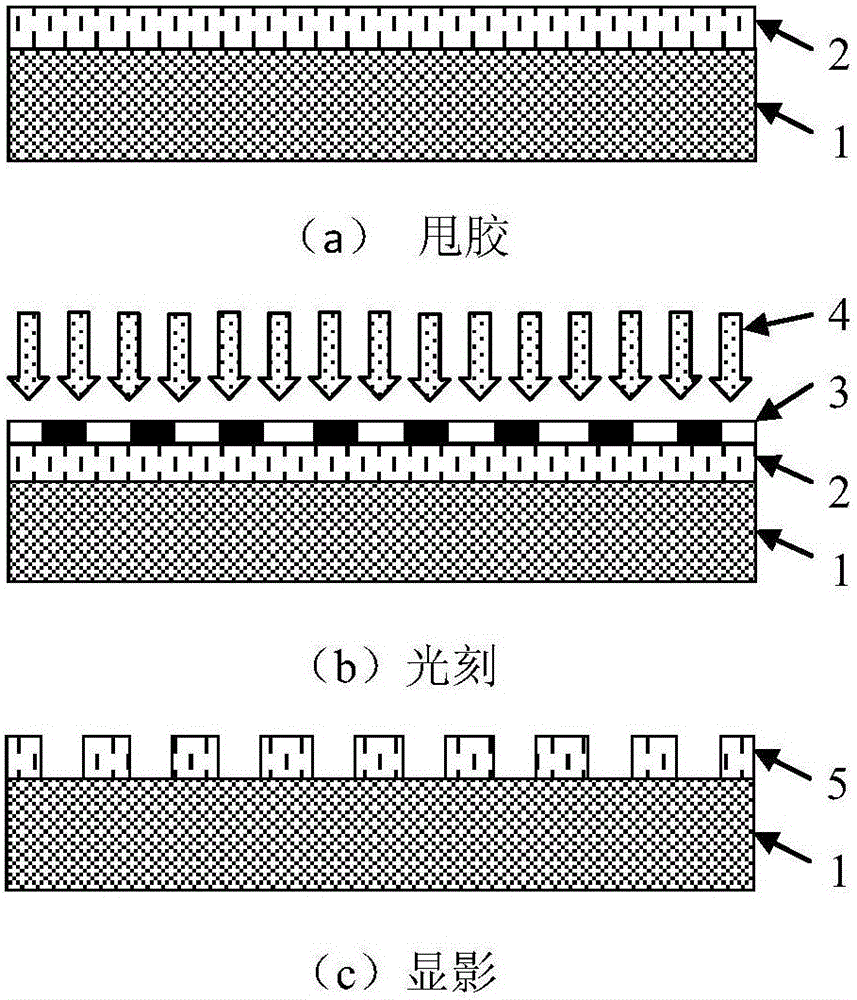

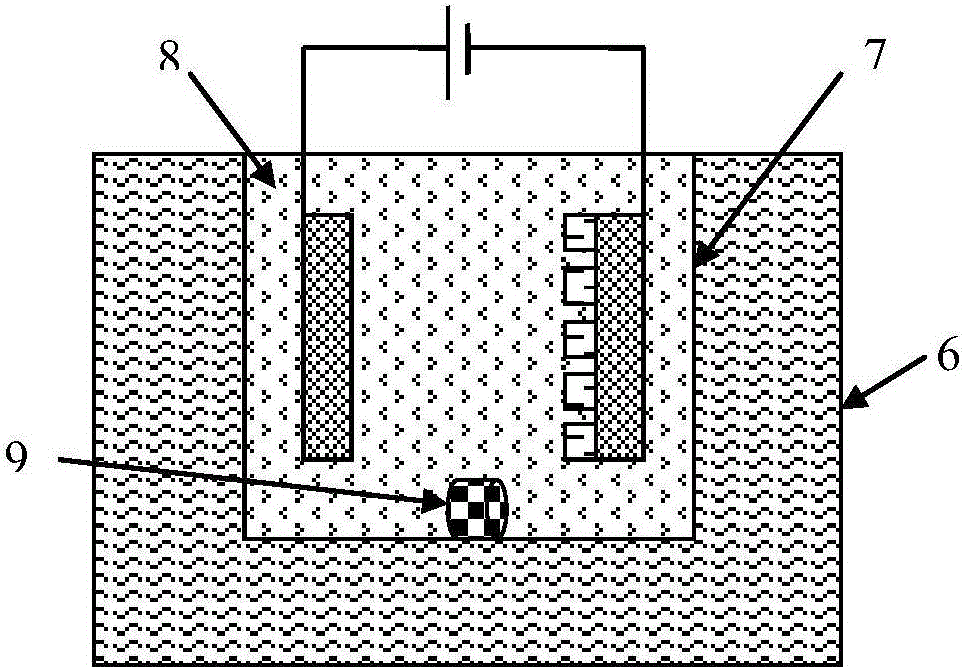

[0024] attached figure 1 It is a schematic diagram of a metal microspring mask plate used for photolithography. The overall size of the microstructure is 3.74mm×1.14mm, and the minimum line width of the spring is 25um. Based on attached figure 2 In the UV-LIGA process shown, the metal microstructure electroformed adhesive film was produced. later attached image 3 Co-deposition of solid particles with metal microstructures is performed in the micro-electroforming apparatus shown. A method for measuring the residual stress of metal microstructures, which comprises the following steps:

[0025] (1) Pretreatment of solid particles with Raman activity. First, weigh 20g of SiC solid particles with a particle size of 5um and pour them into a 500ml beaker, wash the solid particles with deionized water, and filter to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com