Wind tunnel model 3D ice shape on-line measuring method based on three-dimensional ultrasonic imaging technology

A measurement method, a three-dimensional ultrasonic technology, applied in the testing of measuring devices, machines/structural components, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of destroying ice shape, not being able to measure in real time, and being less destructive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

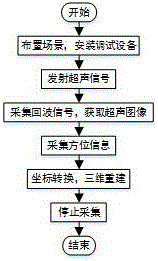

[0048] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

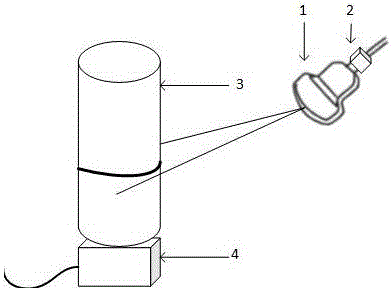

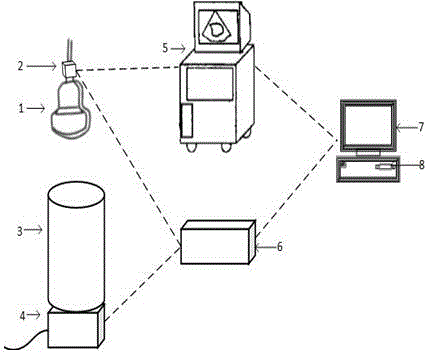

[0049] Labels in the figure: 1—ultrasonic probe, 2—transmitting end of electromagnetic positioning sensor, 3—object to be measured, 4—receiving end of electromagnetic positioning sensor, 5—ultrasonic instrument, 6—controller, 7—microcomputer, 8—image acquisition card , 9—echo signal receiving unit, 10—echo signal delay unit, S(i) represents the echo signal, S(o) represents the echo signal after delay superposition beamforming, Indicates the ultrasonic scanning plane, Represents a 2D ultrasound image plane.

[0050] The wind tunnel model 3D ice shape online measurement system based on ultrasonic imaging technology such as figure 1 As shown, the measurement device includes: an ultrasonic instrument, a microcomputer, a color image acquisition card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com