Thermal engineering experiment thermal balance environment automatic control device and control method thereof

A technology of automatic control device and thermal experiment, which is applied in the direction of temperature control using electric method, auxiliary controller with auxiliary heating device, material thermal development, etc. Simple and compact, improve accuracy and reliability, maintain stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

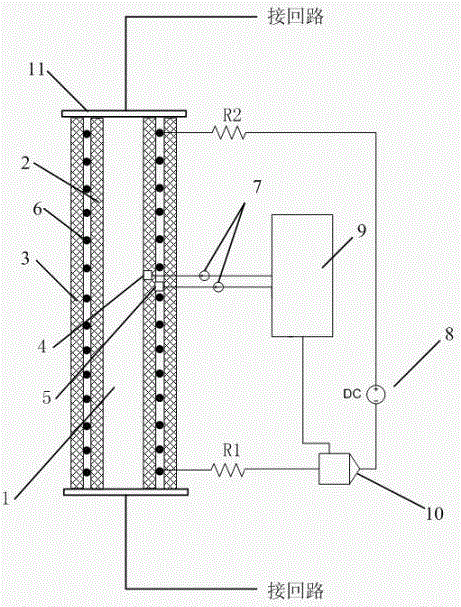

[0031] Such as figure 1 As shown, in the thermal experiment, the two ends of the experimental pipe section 1 are generally connected to the circuit through the connecting flange 11, so that the experimental working medium flows from the circuit through the experimental pipe section 1 and then flows into the circuit.

[0032] figure 1 It is a cross-sectional view of the experimental pipe section 1 and the automatic control device for the heat balance environment of the thermal experiment along the axial direction of the experimental pipe section 1. The automatic control device for the heat balance environment of the thermal experiment in this embodiment includes an inner layer of insulation layer 2, an outer layer of insulation layer 3, and a thermal insulation layer. Compensation wire 6, wherein:

[0033] The inner insulation layer 2 is wrapped on the outer wall of the experimental pipe section 1, the thermal compensation wire 6 is evenly wound outside the inner insulation la...

Embodiment 2

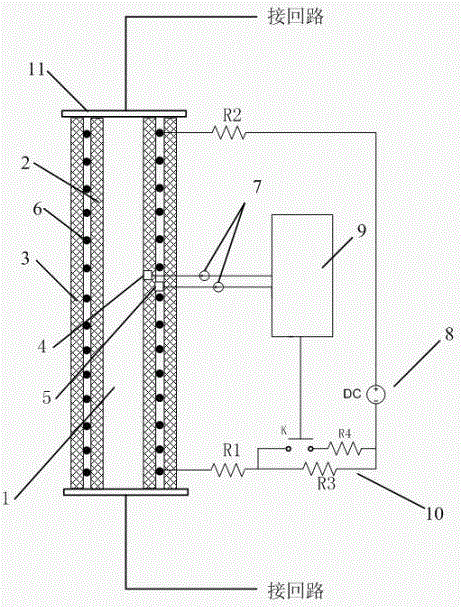

[0036]On the basis of Embodiment 1, in order to improve the controllability of heating during thermal compensation, the thermal experiment thermal balance environment automatic control device in this embodiment also includes two thermocouples 7, and the temperature signals collected according to the two thermocouples 7 A feedback circuit for adjusting the heating power of the thermal compensation wire 6 is connected to the series loop.

[0037] The outer wall of the experimental pipe section 1 is provided with a first measuring point 4, and the outer wall of the inner layer insulation layer 2 is provided with a second measuring point 5, and each of the first measuring point 4 and the second measuring point 5 is connected with a thermocouple 7 , two thermocouples 7 are connected to the feedback circuit, and the two thermocouples 7 are respectively used to collect the temperature signal of the outer wall of the experimental pipe section 1 and the temperature signal of the outer w...

Embodiment 3

[0040] On the basis of Embodiment 2, the feedback circuit in this embodiment is further improved:

[0041] Described feedback circuit comprises operational controller 9 and feedback device 10, and operational controller 9 has two input ends, and its two input ends respectively connect a thermocouple 7, and output end connects feedback device 10, and operational controller 9 pairs two The temperature signals collected by the thermocouple 7 are compared, and a control signal is output to the feedback device according to the comparison result; the feedback device 10 is connected in series between the thermal compensation power supply 8 and the thermal compensation wire 6, and the current of the series circuit is adjusted according to the control signal of the operation controller 9 .

[0042] Further, in order to prevent the current on the series loop from being too large, a current limiting resistor is connected in series on the series loop. In this embodiment, a current limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com