Low-loss type magneto-optical gap magnetic surface quick wave any-angle unidirectional turning waveguide

A magnetic surface, arbitrary angle technology, applied in one-way transmission and bending waveguide, magneto-optical materials, magnetic surface wave field, can solve the problems of polarization angle loss, unsuitable Faraday isolator, complex structure, etc., to achieve ultra-low loss, The effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

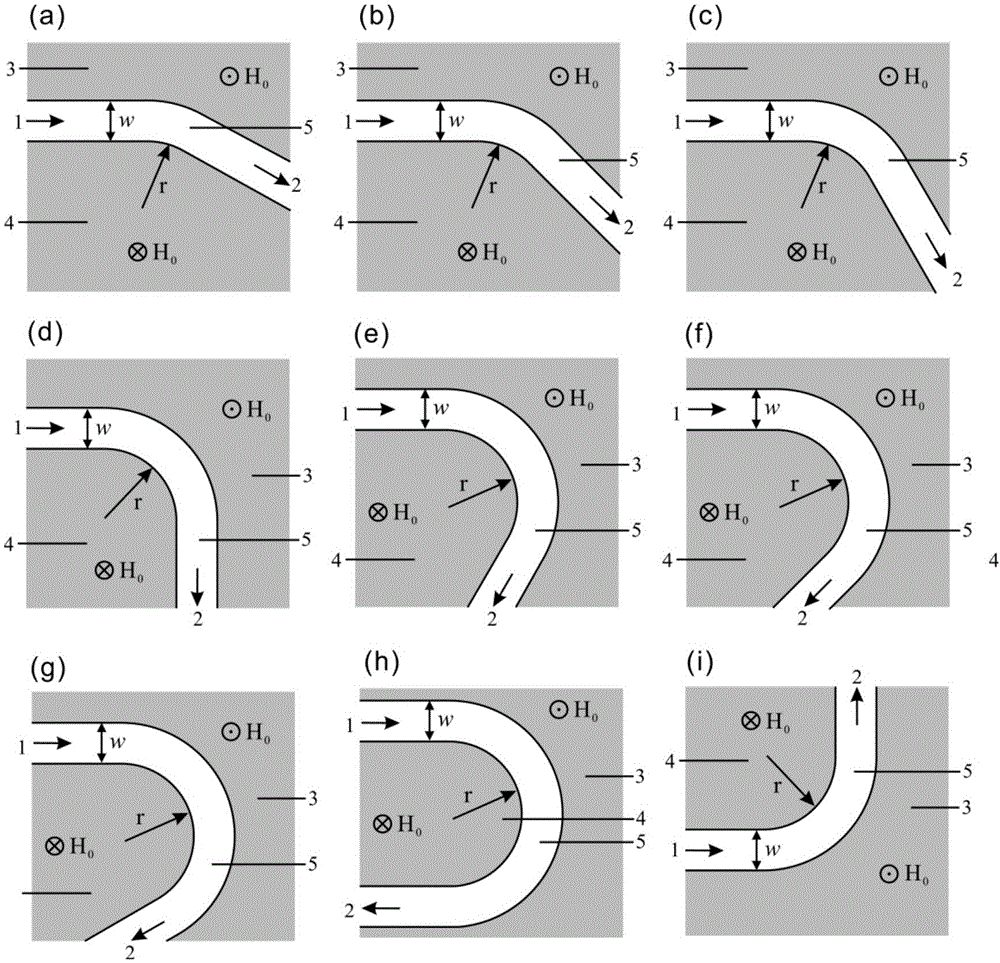

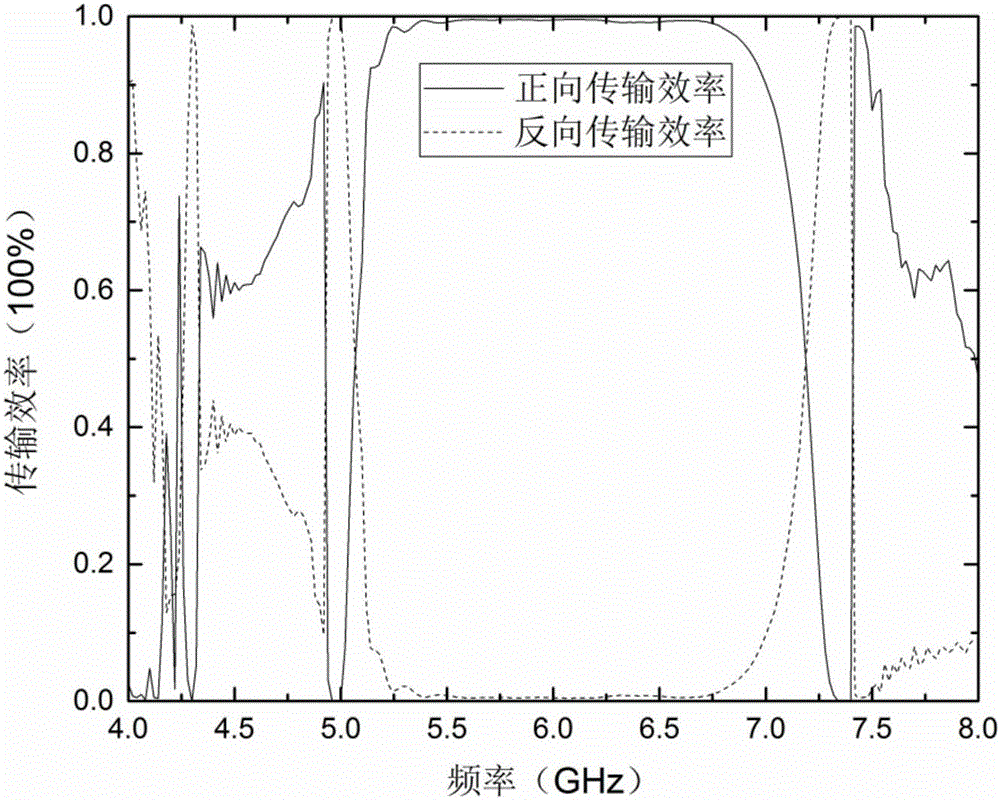

[0045] refer to figure 1 (b), the one-way turning waveguide is composed of a magneto-optical gap waveguide, and the turning angle is 45 degrees. In the working frequency band, the light wave input from port 1 will generate magnetic surface waves inside the device, and then output from port 2 through the device; while the light wave input from port 2 will be blocked by the device and cannot be output from port 1. refer to image 3 , the operating frequency range of the one-way bend waveguide is 5.12GHz to 7.16GHz. In the operating frequency range, considering the material loss, the unidirectional bend waveguide can achieve a maximum forward and reverse transmission isolation of 23.6552dB, and a forward transmission insertion loss of 0.0194dB.

Embodiment 2

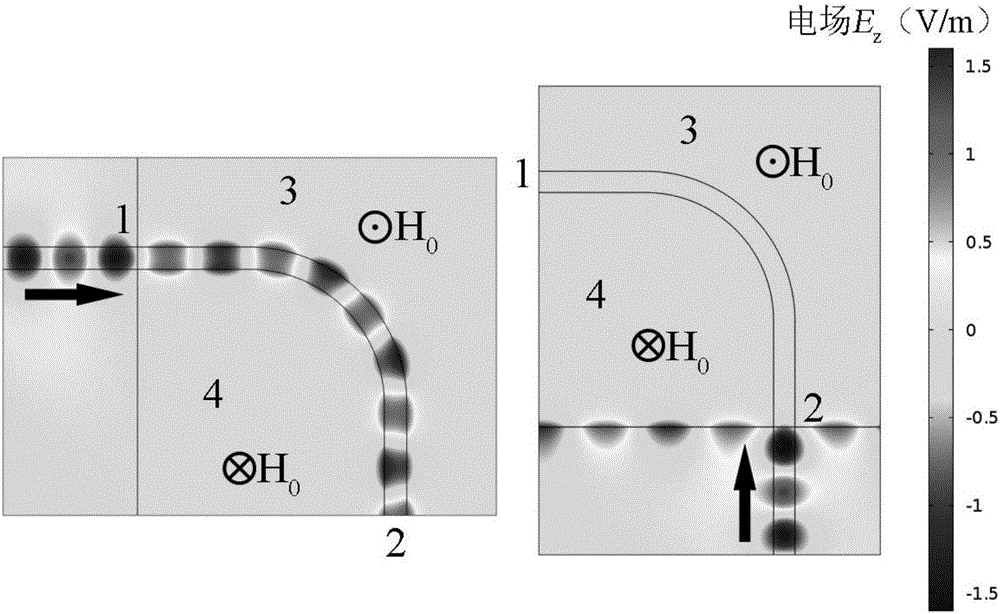

[0047] refer to figure 1 (d) and (i), the one-way turning waveguide is composed of a magneto-optical gap waveguide, and the turning angle is 90 degrees. In the working frequency band, the light wave input from port 1 will generate magnetic surface waves inside the device, and then output from port 2 through the device; while the light wave input from port 2 will be blocked by the device and cannot be output from port 1. refer to Figure 4 , The operating frequency range of the one-way bend waveguide is 5.10GHz to 7.22GHz. In the operating frequency range, considering the material loss, the unidirectional bend waveguide can achieve a maximum forward and reverse transmission isolation of 25.8838dB, and a forward transmission insertion loss of 0.0112dB.

Embodiment 3

[0049] refer to figure 1 (f), the one-way turning waveguide is composed of a magneto-optical gap waveguide, and the turning angle is 135 degrees. In the working frequency band, the light wave input from port 1 will generate magnetic surface waves inside the device, and then output from port 2 through the device; while the light wave input from port 2 will be blocked by the device and cannot be output from port 1. refer to Figure 5 , the operating frequency range of the one-way bend waveguide is 5.10GHz to 7.18GHz. In the operating frequency range, considering the material loss, the unidirectional bend waveguide can achieve a maximum forward and reverse transmission isolation of 23.6067dB, and a forward transmission insertion loss of 0.0120dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com