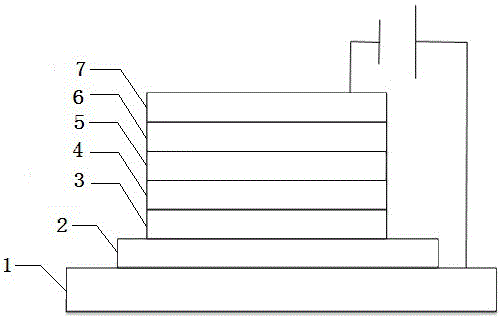

NiO-doped light-emitting diode and preparation method therefor

A light-emitting diode, 2·6H2O technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of nickel oxide work function not reduced, unable to react and prepare, etc., to achieve the effect of improving the ability of hole transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

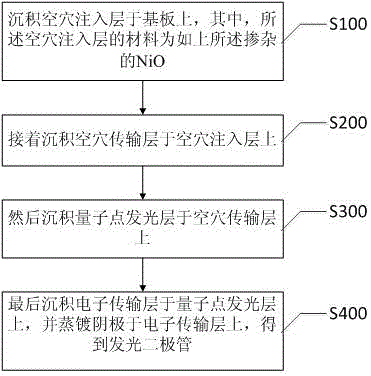

Embodiment 1

[0037] 0.8mmol of Ni(NO 3 ) 2 •6H 2 O and 0.015mmol of Cu(NO 3 ) 2 2.5H 2 O (or Zn (NO 3 ) 2 •6H 2 O or Zn(NO 3 )2 ) and 0.05mmolLiNO 3 Dissolve in 10mL deionized water, add 0.1mol glycine, then add 8uL NH 3 •H 2 O solution. Then the configured solution is deposited on the substrate containing the bottom electrode and heated at 170 °C to generate Li x Cu y NiO film (or Li x Zn y NiO film), wherein the values of x and y can be adjusted according to different hole transport layers or different preparation conditions.

Embodiment 2

[0039] 0.8mmol of Ni(NO 3 ) 2 •6H 2 O and 0.015mmol of Cu(NO 3 ) 2 2.5H 2 O (or Zn (NO 3 ) 2 •6H 2 O or Zn(NO 3 ) 2 ) and 0.05mmolLiNO 3 Dissolve in 10mL deionized water, add 0.05mol glycine and 5ul acetylacetone, then add 8uL NH 3 •H 2 O solution. Then the configured solution is deposited on the substrate containing the bottom electrode and heated at 170 °C to generate Li x Cu y NiO film (or Li x Zn y NiO film), wherein the values of x and y can be adjusted according to different hole transport layers or different preparation conditions.

Embodiment 3

[0041] 0.8mmol of Ni(NO 3 ) 2 •6H 2 O and 0.015mmol of Mg (NO 3 ) 2 and 0.05mmolLiNO 3 Dissolve in 10mL of 2-methoxyethanol solution, add 10uL of acetylacetone solution, add 7uL of NH 3 •H 2 O solution. Then the configured solution is deposited on the substrate containing the bottom electrode and heated at 190 °C to generate Li x Mg y A NiO thin film, wherein the values of x and y can be adjusted according to different hole transport layers or different preparation conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com