Ficus carica cuttage cultivation soil formula

A fig and formula technology, applied in cultivation, culture medium, inorganic fertilizer, etc., can solve the problems of unfavorable fig promotion, low economic benefit, easy plant death, etc., and achieve the effect of reducing difficulty, improving economic benefit and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

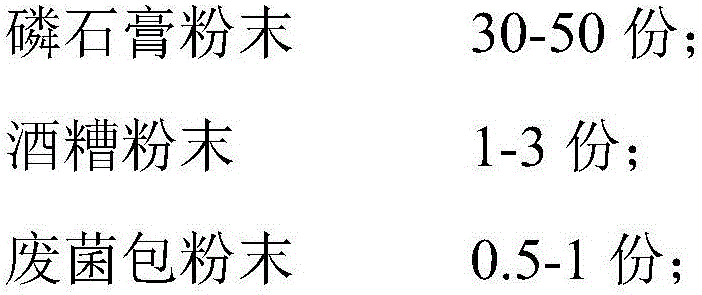

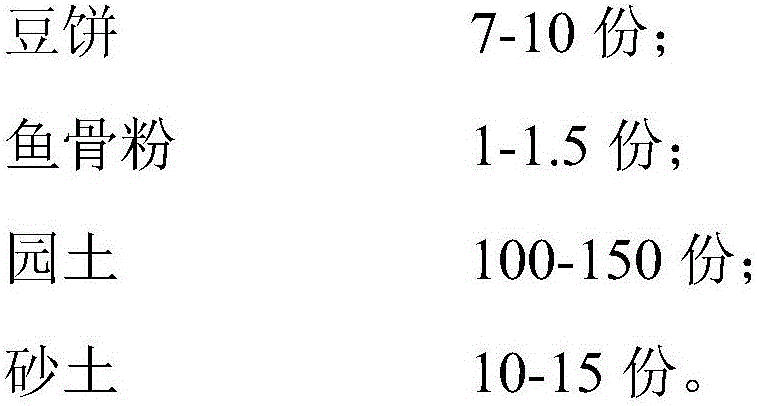

[0016] A fig cutting cultivation soil formula, the formula is composed of the following raw materials in parts by weight:

[0017]

[0018]

[0019] The phosphogypsum powder is obtained by processing waste phosphogypsum produced by wet-process phosphoric acid. The specific processing method is: drying the phosphogypsum at 75-85°C for 2-3 hours, and drying The final phosphogypsum is crushed into powder with a fineness of not less than 180 mesh.

[0020] The production method of the distiller's grain powder is as follows: firstly, the distiller's grains are dried by heating until the water content in the distiller's grains reaches 13-15%; Powder; the temperature during the drying process of distiller's grains should be controlled at 90-110°C.

[0021] The production method of the waste bacteria bag powder is as follows: firstly, the waste bacteria bag is dried by heating until the water content in the distiller’s grains reaches 15-17%; then, the dried waste bacteria bag i...

Embodiment 2

[0028] The following formula is used for the cultivation soil in this embodiment: 30 parts of phosphogypsum powder; 1 part of distiller's grain powder; 0.5 part of waste bacterial bag powder; 7 parts of bean cake; 1 part of fish bone meal; 100 parts of garden soil; 10 parts of sandy soil.

[0029] 150 fig struts were respectively inserted into boiled water, garden soil and the cultivation soil of the above formula, and 50 fig struts were respectively inserted into the boiled water, garden soil and the cultivation soil of the above formula, and observed and recorded. In the experiment, except for the cultivation environment, all other conditions were the same. The specific data are shown in Table 1 below:

[0030] nurturing environment boiled water garden soil Cultivate the soil Number of dead (roots) 13 18 1 Rooting time (days) 27-35 26-33 13-17

[0031] Table 1

[0032] As can be seen from the above table, the overall mortality rate of the...

Embodiment 3

[0034] The following formula is used for the cultivation soil in this embodiment: 50 parts of phosphogypsum powder; 3 parts of distiller's grain powder; 1 part of waste bacterial bag powder; 10 parts of bean cake; 1.5 parts of fish bone meal; 150 parts of garden soil; 15 parts of sandy soil.

[0035] 150 fig struts were respectively inserted into boiled water, garden soil and the cultivation soil of the above formula, and 50 fig struts were respectively inserted into the boiled water, garden soil and the cultivation soil of the above formula, and observed and recorded. In the experiment, except for the cultivation environment, all other conditions were the same. The specific data are shown in Table 2 below:

[0036] nurturing environment boiled water garden soil Cultivate the soil Number of dead (roots) 11 19 0 Rooting time (days) 26-35 25-31 12-15

[0037] Table 2

[0038] As can be seen from the above table, the overall mortality rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com