Instantaneous Pressure Difference Sterilization Method and Its Application in Apple Powder Sterilization

A technology of apple powder and differential pressure, applied in the fields of application, food science, food preservation, etc., can solve the problems of restricting the production and sales of irradiated food, and achieve the effects of mature production equipment, improved rehydration characteristics, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

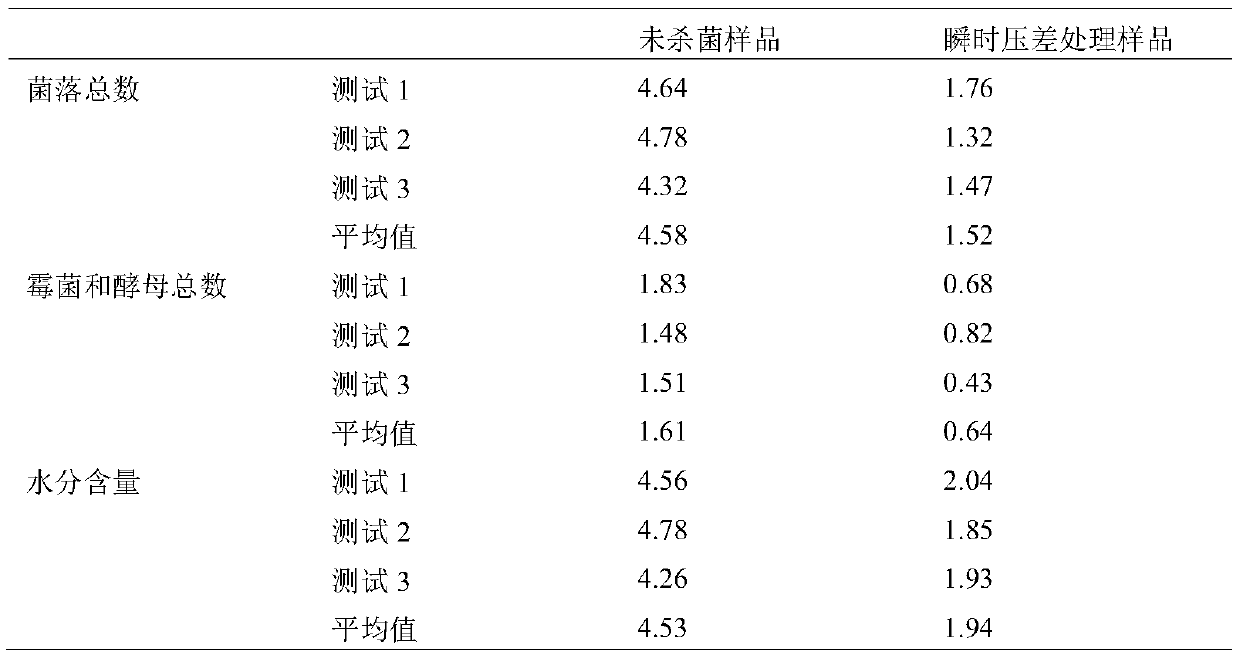

Embodiment 1

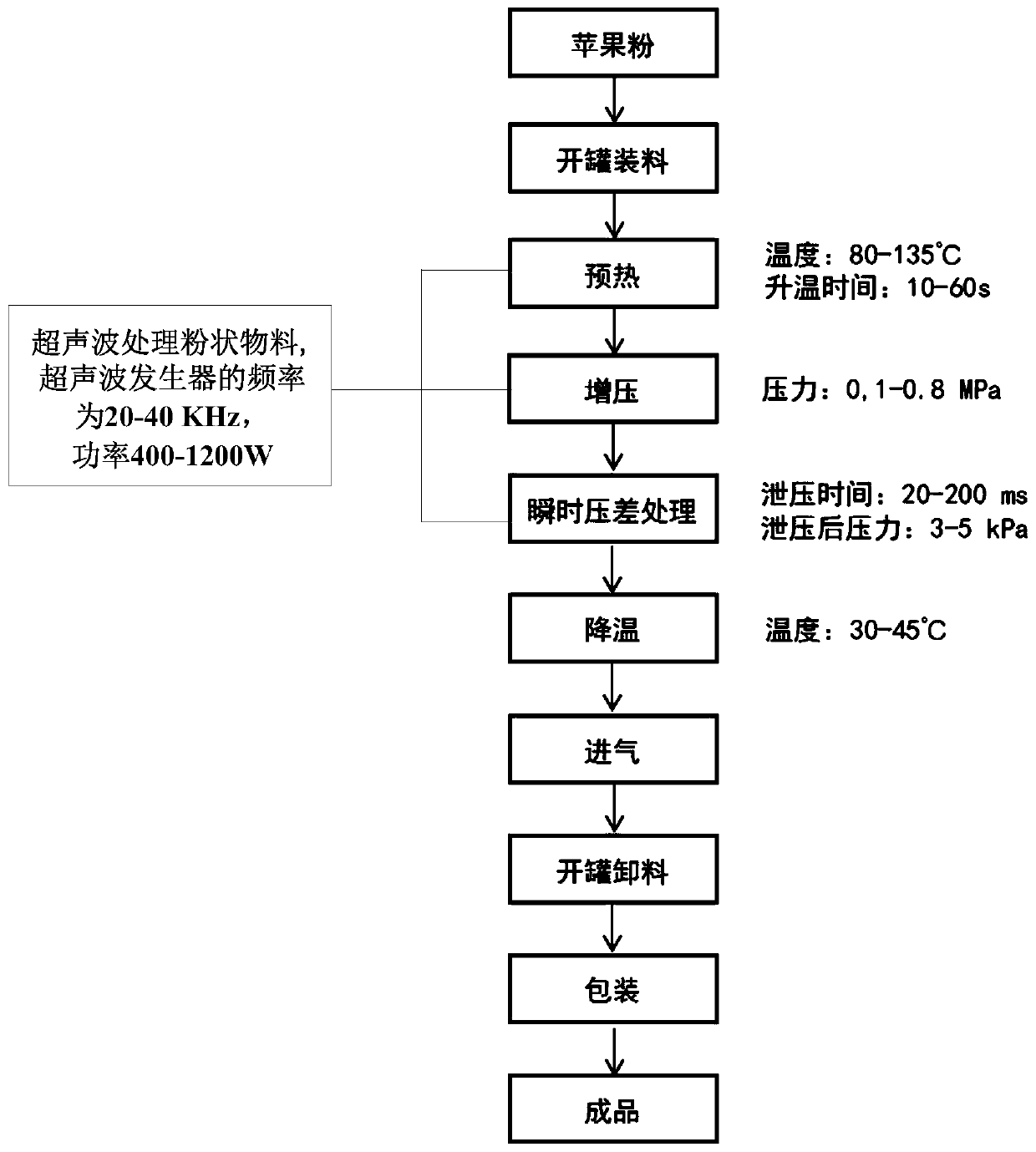

[0054] Such as figure 1 Shown, the present invention provides the present invention provides a kind of method utilizing instantaneous differential pressure treatment that apple powder is sterilized, mainly comprises the following steps:

[0055] (1) Put the apple powder in the processing chamber of the instantaneous pressure difference equipment, preheat the apple powder, and directly inject saturated steam to heat the material, and the specific temperature after heating is 120°C, and the heating time is 30s ; While preheating, turn on the ultrasonic generator, adjust the frequency to 20KHz, and power to 400W;

[0056](2): Use high-pressure air to pressurize the processing chamber, wherein the pressurization time is 90s, and the pressure of the processing chamber after pressurization is 0.3MPa;

[0057] (3): Open the pressure relief valve to perform instantaneous differential pressure treatment on the materials in the processing bin, wherein the pressure relief time is 80ms, ...

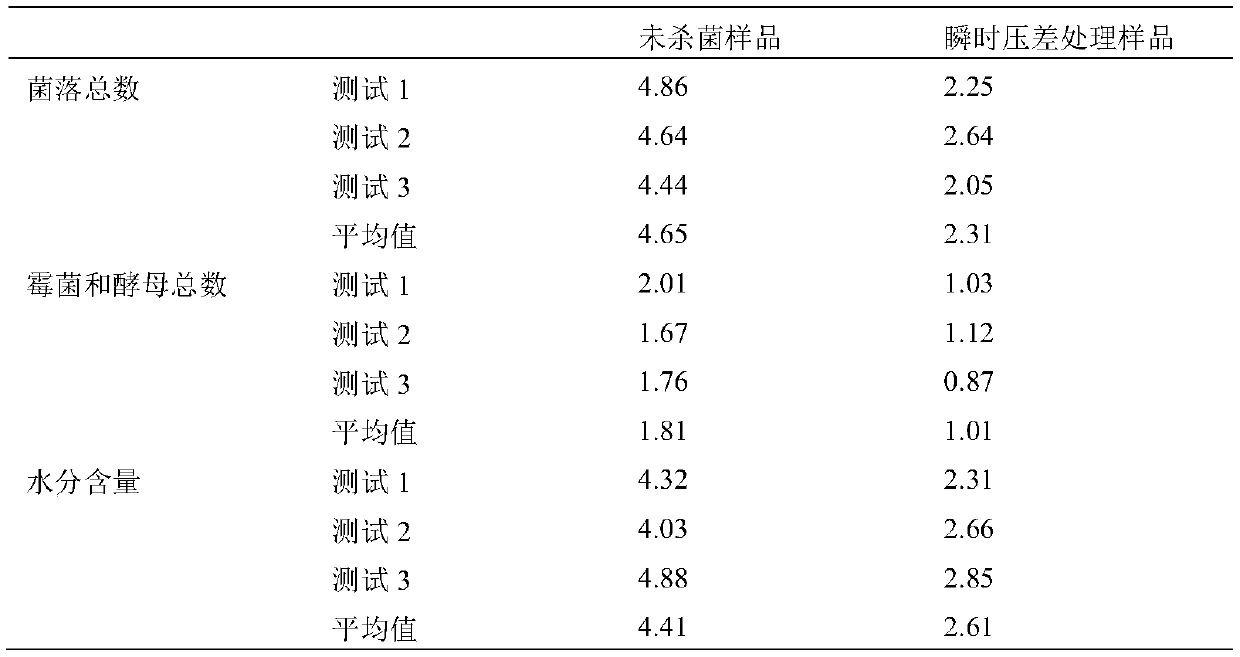

Embodiment 2

[0067] Such as figure 1 Shown, the present invention provides the present invention provides a kind of method utilizing instantaneous differential pressure treatment that apple powder is sterilized, mainly comprises the following steps:

[0068] (1) Put the apple powder in the processing chamber of the instantaneous pressure difference equipment, preheat the apple powder, and use the steam pipe to heat indirectly. Generator, adjustable frequency is 40KHz, power 1200W;

[0069] (2): Use high-pressure air to pressurize the processing chamber, wherein the pressurization time is 10s, and the pressure of the processing chamber after pressurization is 0.6MPa;

[0070] (3): Open the pressure relief valve to perform instantaneous differential pressure treatment on the materials in the processing bin, wherein the pressure relief time is 120ms, and the pressure after pressure relief is 4kPa; after the pressure relief is completed, turn off the ultrasonic generator;

[0071] (4): cooli...

Embodiment 3

[0079] Such as figure 1 Shown, the present invention provides the present invention provides a kind of method utilizing instantaneous differential pressure treatment that apple powder is sterilized, mainly comprises the following steps:

[0080] (1) Put the apple powder in the processing chamber of the instantaneous pressure difference equipment, preheat the apple powder, and use saturated steam to directly contact the material for heating. The specific temperature of the temperature rise is 135°C, and the temperature rise time is 40s; Turn on the ultrasonic generator, adjust the frequency to 28KHz, and the power to 800W;

[0081] (2): Use high-pressure air to pressurize the processing chamber, wherein the pressurization time is 60s, and the pressure of the processing chamber after pressurization is 0.6MPa;

[0082] (3): Open the pressure relief valve to perform instantaneous differential pressure treatment on the materials in the processing bin, wherein the pressure relief t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com