Slab separating membrane and preparation method thereof

A technology for separating membrane and flat plate, which is applied in the field of membrane separation and can solve problems such as filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] In this example, an ultrafiltration membrane with a molecular weight cut off of 5KD was prepared.

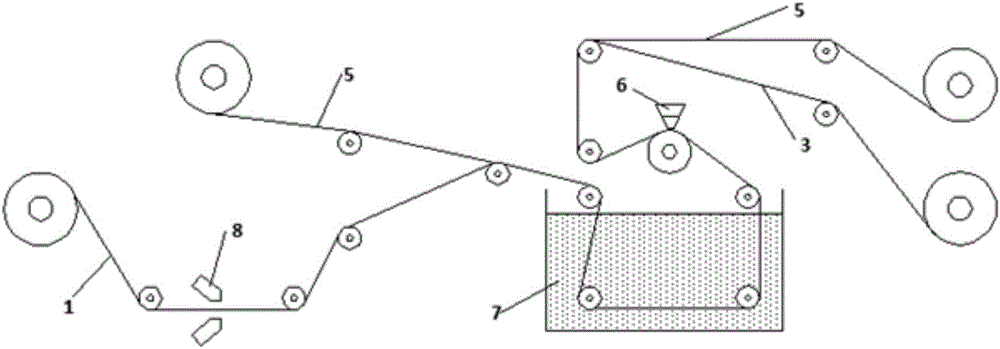

[0093] Using a film coating machine, the casting solution containing 28wt% polyethersulfone, 65wt% formamide and 7wt% polyethylene glycol 600 was stirred at 60°C for 5 hours, and then placed at room temperature for 72 hours. Remove the air bubbles.

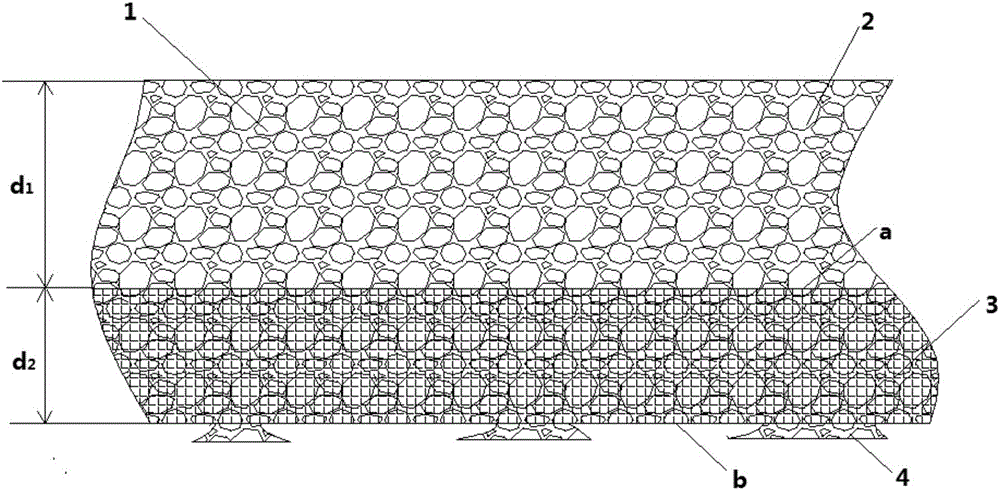

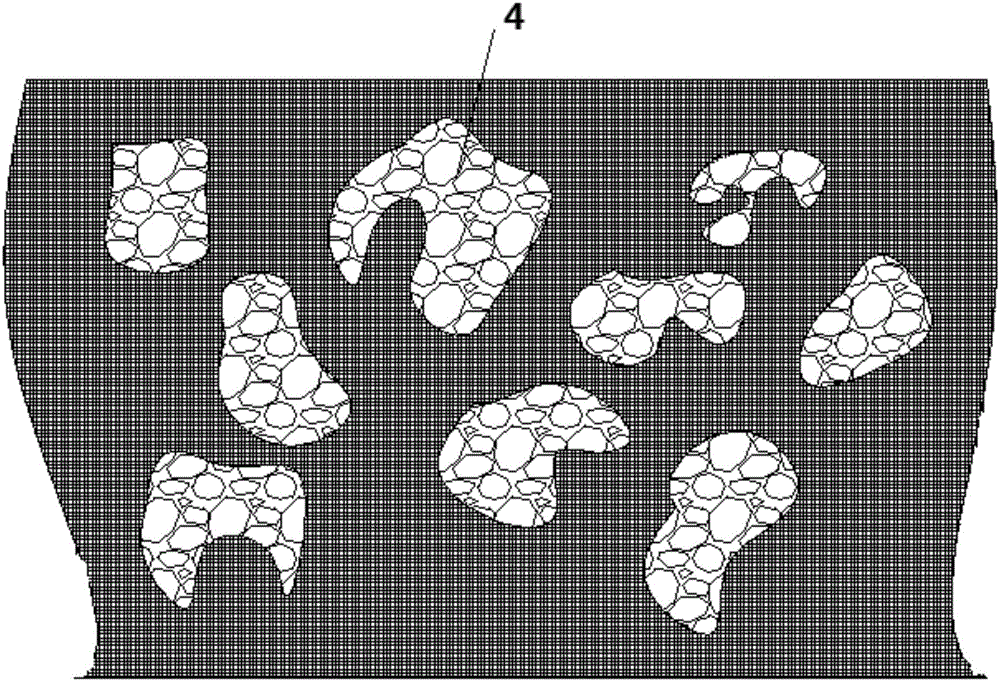

[0094] Under the action of the film coating machine, the casting solution is coated on a polypropylene and polyethylene polymer non-woven fabric with a thickness of about 0.12 mm (purchased from Freudenberg Baoling Non-woven Fabric (Suzhou) Co., Ltd., model : 2470) on one side a, the other side b of the non-woven fabric is pasted with a peelable film, the thickness of the film is 0.15 mm, and hollow areas are distributed on the film (or the side of the film in contact with the non-woven fabric) spaced with recessed areas). The coating speed is 5 meters per minute, and the coating thickness of the casting solution on the non...

Embodiment 2

[0102] The present embodiment is an ultrafiltration membrane with a molecular weight cut off of 50KD.

[0103] Using a film coating machine, the casting solution containing 21wt% polyacrylonitrile, 59wt% formamide and 20wt% polyvinylpyrrolidone was stirred at 50°C for 5 hours, and then placed at room temperature for 72 hours to remove it. bubble.

[0104] Under the action of the film coating machine, the casting solution is coated on one side a of a polyester (purchased from Teijin Co., Ltd., model: E55080-60) non-woven fabric with a thickness of about 0.08mm, and the other side of the non-woven fabric b is pasted with a peelable film, the thickness of which is 0.2 mm, and hollow areas are distributed on the film at intervals (or recessed areas are distributed at intervals on the side of the film in contact with the non-woven fabric). The film coating speed is 12 meters per minute, and the film thickness is controlled to be about 0.15mm.

[0105] The residence time before en...

Embodiment 3

[0110] In this example, an ultrafiltration membrane with a molecular weight cut off of 100KD was prepared.

[0111] Using a coating machine, the casting solution containing 18wt% cellulose acetate, 36wt% dioxane, 40wt% formamide and 6wt% lithium chloride was stirred at 50°C for 5 hours, and then placed in a normal temperature environment Place it for 72 hours to remove the air bubbles.

[0112] Under the action of the coating machine, the casting solution is coated on one side a of a polyester non-woven fabric with a thickness of 0.15 mm (purchased from Awa Paper Co., Ltd., model: 150), and the other side b of the non-woven fabric A peelable film is pasted, the thickness of the film is 0.3mm, and hollow areas are distributed on the film at intervals (or recessed areas are distributed at intervals on the side of the film in contact with the non-woven fabric). The coating speed is 5 meters per minute, and the thickness of the coating film is controlled to be about 0.26mm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com