Electroplastic cross wedge mill

A cross wedge rolling mill and electroplastic technology, applied in metal rolling and other directions, can solve the problems of difficult to achieve cold rolling process, ununiform temperature of rolling pieces, low surface quality of products, etc., to save additional equipment, oxidation phenomenon, etc. Reduced, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

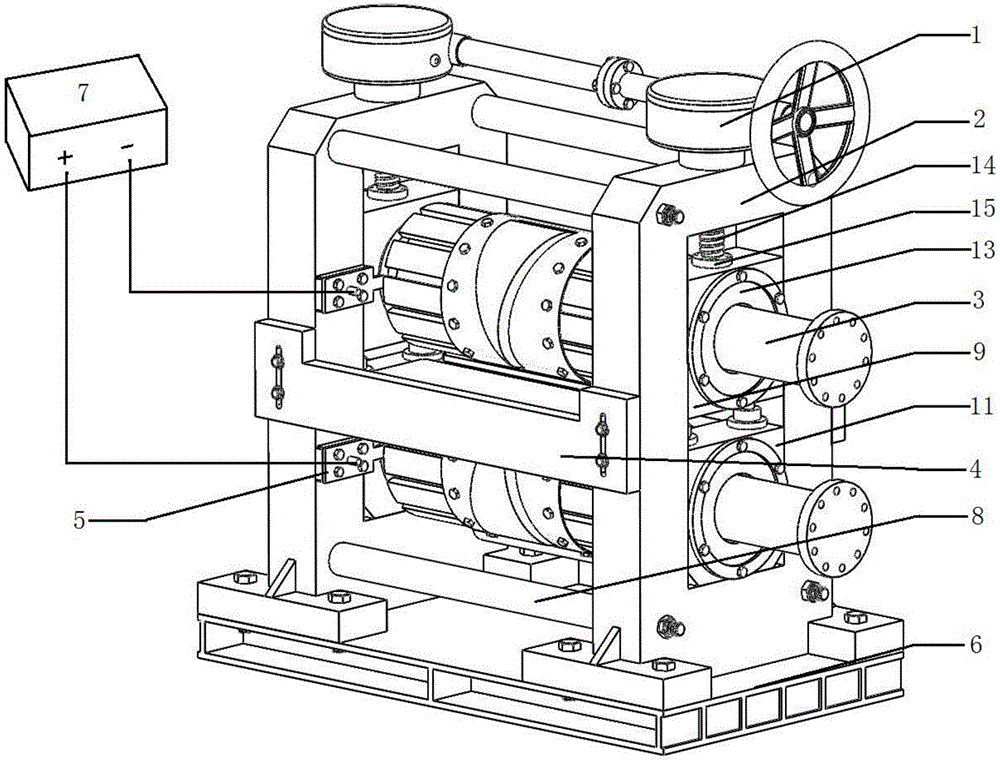

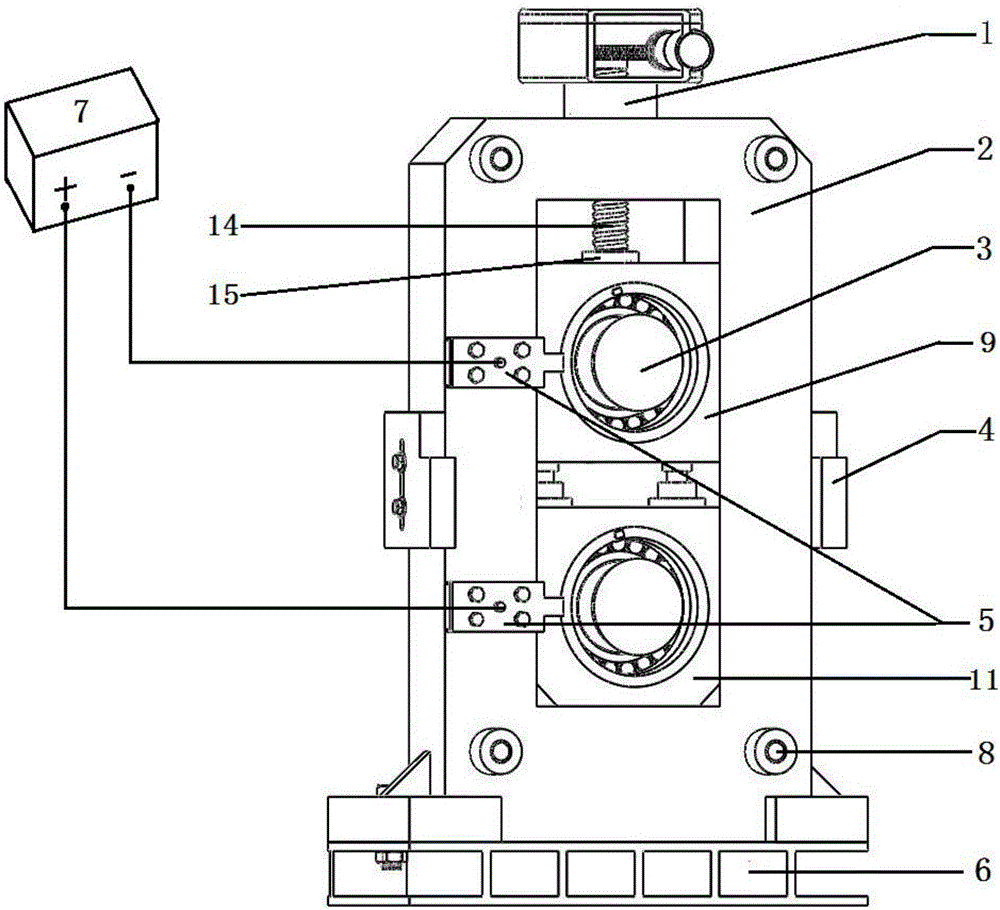

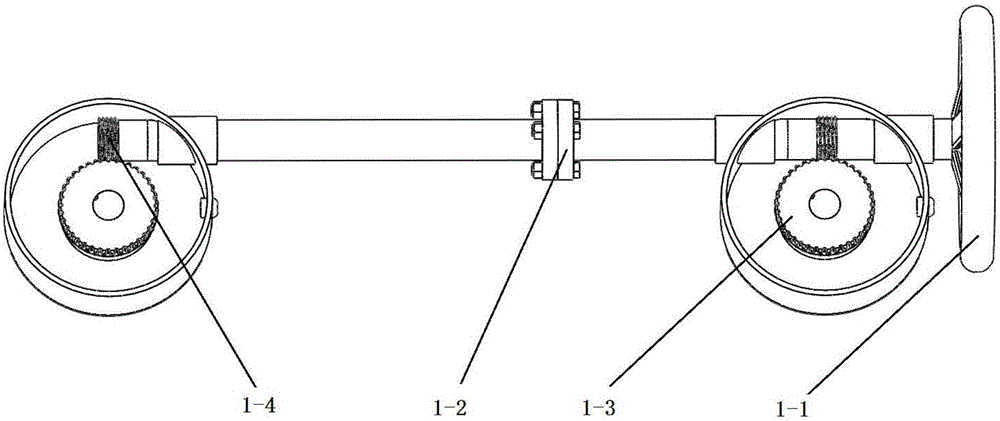

[0026] exist figure 1 , figure 2 , image 3 and Figure 4In the schematic diagram of the electroplastic cross wedge rolling mill shown, the base 6 is a hollow shell, and the upper part of the base is fixedly connected with two frames 2 by bolts. The frame is a rectangular frame, and four connecting rods 8 are connected by bolts between the two frames. A radial adjustment mechanism 1 is arranged on the upper part of the frame. The radial adjustment mechanism adopts worm gear transmission, the handwheel 1-1 is connected with the worm 1-4, and the two worms are connected through the coupling 1-2, and the worm and the worm gear 1-3 mesh with each other. A left guide plate and a right guide plate are respectively arranged between the side walls of the two racks, and the structures of the left guide plate and the right guide plate are the same. Left guide plate is made up of fixed plate 4-1, adjusting plate 4-2 and support plate 4-3, and fixed plate is a rectangular flat plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com