Surface treatment method for sputtering target material

A sputtering target and surface treatment technology, applied in the target field, can solve the problems of difficult cleaning and removal, slow water evaporation, etc., and achieve the effect of high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

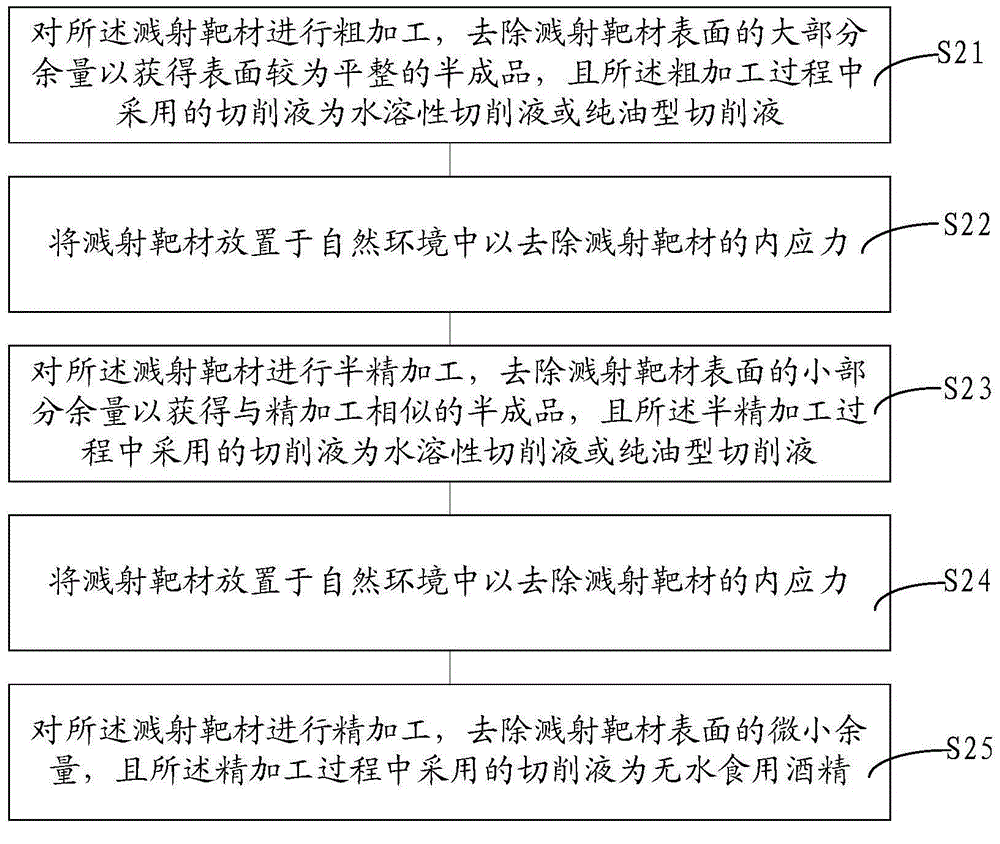

[0029] Through the analysis of the inventor, it is found that the turning process of the existing sputtering target surface treatment technology uses pure oil or water-soluble or pure water as the cutting fluid, but the pure oil or water-soluble cutting fluid may or Will react with the aluminum material of the sputtering target, or contain oily substances, which is difficult to clean, resulting in the formation of cutting fluid residues or water marks on the surface of the sputtering target. It is difficult to use cutting fluid dedicated to aluminum materials. Make sure that no cutting fluid remains on the surface of the sputtering target after processing, which will affect the final use of the sputtering target.

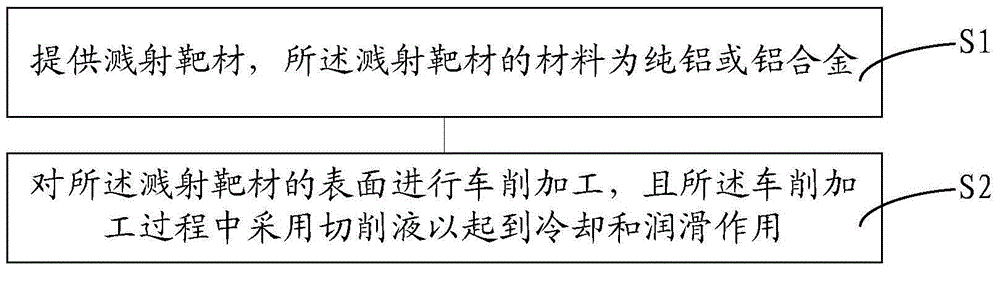

[0030] In order to solve the problem that cutting fluid residues or water marks are easily formed on the surface of the sputtering target when the cutting fluid of the existing turning technology is used, the inventor of the present invention has made further research o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com