Oil storage tank crude oil sampling device

A sampling device and oil storage tank technology, applied in the field of crude oil sampling devices in oil storage tanks, can solve problems such as electrostatic sparks prone to flashover, slippery operation surface of tank mouths, high-altitude falling accidents, etc., so as to improve the working conditions of employees and ensure The effect of explosion-proof safety and improving sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

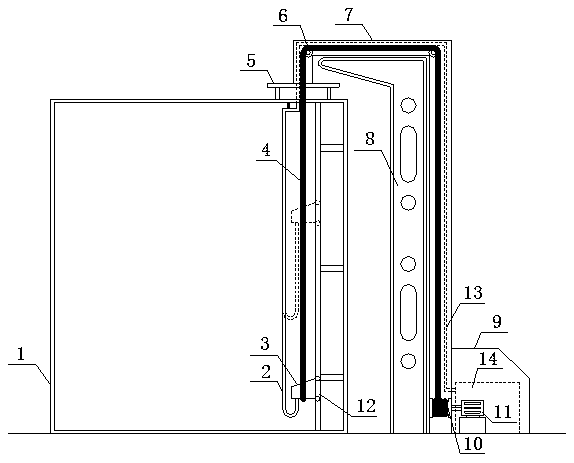

[0031] Such as figure 1 As shown, the crude oil sampling device of the oil storage tank, the device includes a lifting guide rail 12 arranged on the inner wall of the oil tank 1, a shell with a built-in bearing column 8 outside the oil tank 1, and a gas-liquid integrated pipe containing compressed air pipes and oil delivery pipes. 13. The sampling platform 9 connected with the casing.

[0032] A sealing groove 7 is provided inside the casing; a diaphragm pump 3 is provided inside the lifting guide rail 12, and a pipeline towline 2 is connected to the diaphragm pump 3; one end of the pipeline towline 2 is connected to the flange 5 fixed on the top of the oil tank 1 connected; the lifting guide rail 12 is provided with a pulley 6, and the pulley 6 is provided with a lifting wire 4 embedded in the sealing groove 7; On the wire winch 10 at the bottom, the wire winch 10 is connected with a traction motor 11; a part of the pipeline of the gas-liquid integrated pipe 13 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com