High temperature heat conduction water plasma generation system

A plasma and high-temperature heat pipe technology, applied in the field of ions, can solve the problem of not finding HHO fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

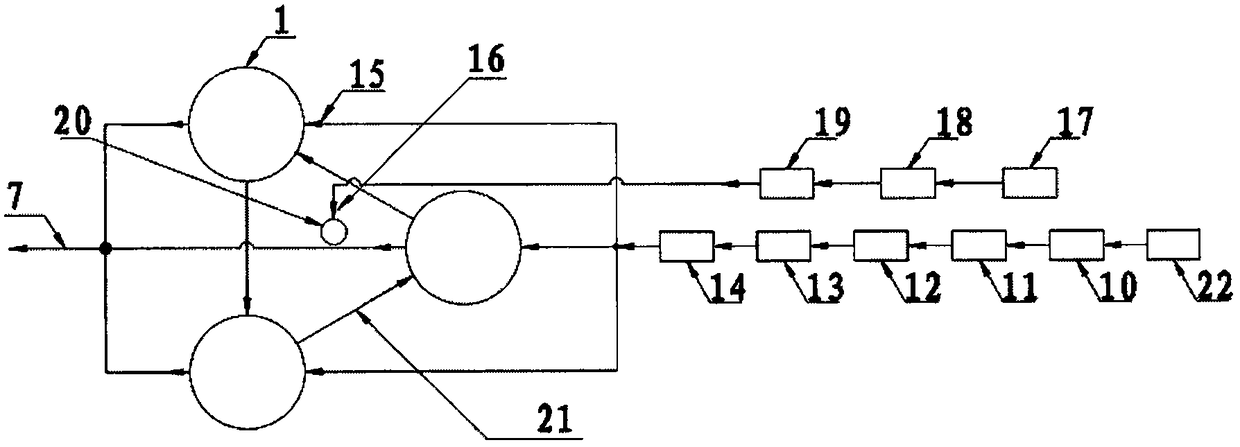

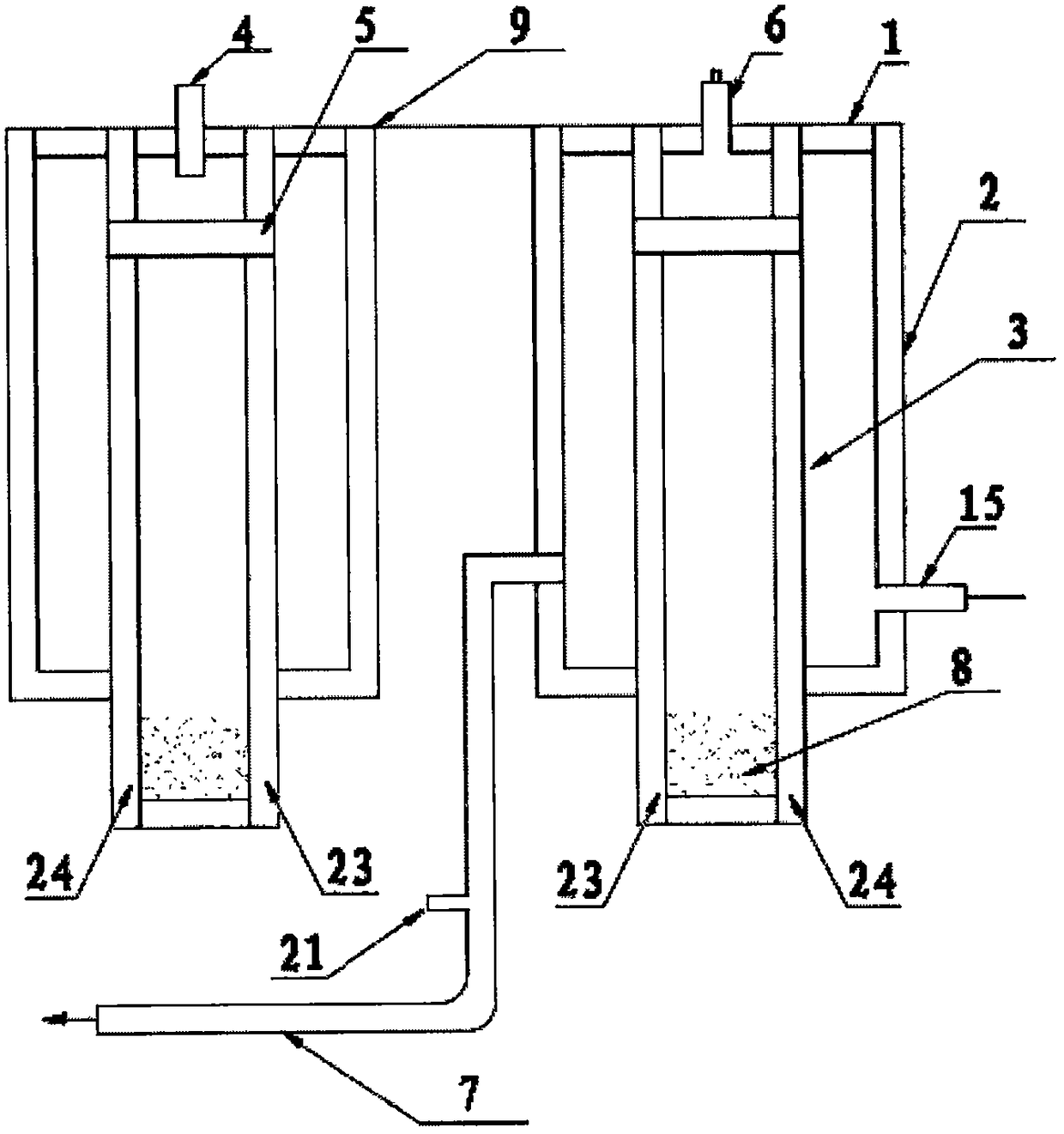

[0022] Embodiment 1, the high temperature heat pipe water (HHO) plasma generation system is installed on the automobile engine

[0023] The high temperature heat pipe water (HHO) plasma generator is installed on the engine exhaust outlet pipe. The water tank is sequentially connected with a filter, a high-pressure diaphragm water pump (specification: 12 volts or 24 volts. 2A, 30W-60W, 6MPA), a solenoid valve, a check valve, a hot water tank, and a water mist nozzle. Three superconducting high-temperature water (HHO) plasma generators are arranged in a triangle, and high-temperature heat pipes are equipped with high-temperature heat transfer medium (specification: metal sodium, working temperature 500°C-1200°C) for rapid heat transfer.

[0024] The working principle of the high-temperature heat pipe water (HHO) plasma generation system device is as follows: the engine is first started to work with methanol fuel oil, and the high-temperature gas from the outlet pipe of the engin...

Embodiment 2

[0025] Example 2, the high temperature heat conduction water (HHO) plasma generation system is installed on a 1 ton boiler

[0026] The water tank of the high-temperature heat conduction water (HHO) plasma generation system is sequentially connected with a filter high-pressure diaphragm water pump (specification: 12V or 24V DC, 2A, 30w-60w / 6Mpa), solenoid valve, check valve, hot water Box, water mist nozzle, and 3 high-temperature heat conduction water (HHO) plasma generators are arranged in a triangle. Metal sodium, a high-temperature heat transfer medium, is also installed in the high-temperature heat pipe.

[0027] Specifications of the heat preservation nozzle of the high-temperature heat pipe water (HHO) plasma generator: its plasma flow rate is one-sixth of the total flow rate of the plasma outlet pipe, and is used for outputting plasma. The high-temperature heat pipe is equipped with a high-temperature heat transfer medium specification: metal sodium, and the working t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com