Novel microwave-based cement production method capable of generating power with waste gas

A new method, cement technology, applied in the field of cement technology, can solve problems such as difficult uniformity of raw material composition, low production heat consumption, and large dust in the workshop, and achieve the effects of shortened firing time, less dust, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

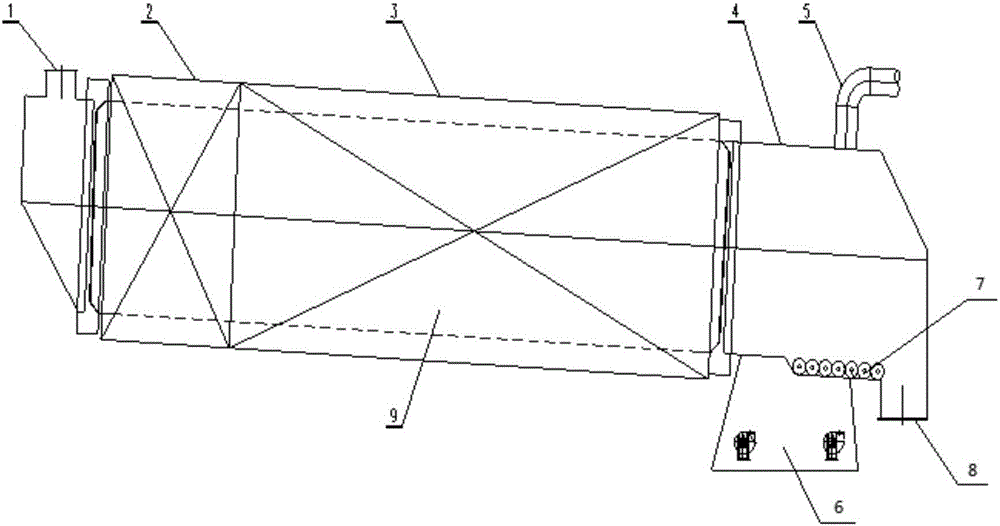

Image

Examples

Embodiment Construction

[0025] This design provides a new method of microwave cement production with waste gas power generation function, the steps are as follows:

[0026] S1: Mixing: Put cement raw meal powder, carbon powder and additives in a certain proportion and put them into a grinder for crushing;

[0027] S2: Shaping: Utilize the ball forming machine to shape the compound after pulverizing in the step S1, and make it into a pellet;

[0028] S3: Combustion and decomposition: put the pellet-shaped mixture into a microwave combustion furnace for calcination and decomposition to generate cement clinker;

[0029] S4: Exhaust gas power generation: collecting the tail gas decomposed in step S3, and transporting these high-temperature tail gases into a thermal generator for power generation;

[0030] S5: Tail gas treatment: desulfurize and denitrify the low-temperature tail gas after power generation in step S4, and then discharge it into the atmosphere;

[0031] S6: cooling and feeding: the cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com