Patents

Literature

35results about How to "Has a catalytic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

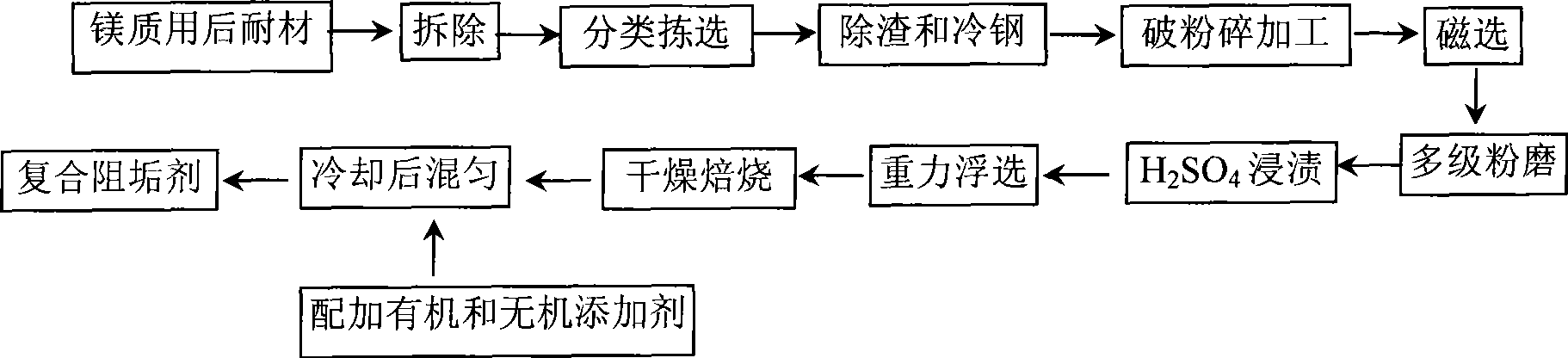

Use of magnesium used refractory, preparation and use method of composite scale inhibitor

ActiveCN101396634AReduce manufacturing costEasy to processDispersed particle separationTreatment using complexing/solubilising chemicalsSlagStrong acids

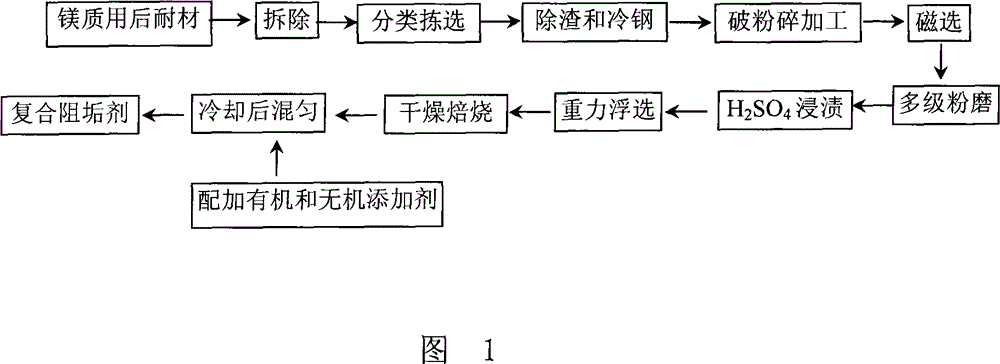

The invention discloses a usage of magnesium used refractory material as well as the preparation and using method of a compound scale inhibitor, and is characterized in that the magnesium used refractory material which is the waste of industry is used for preparing the compound scale inhibitor. The method for preparing the compound scale inhibitor comprises the steps: 1) the magnesium used refractory material which is the waste of industry is sequentially treated by sorting, removing slag and chilled steel, grounding processing, magnetic separation and removal of iron as well as multilevel grounding, and then made into powder; 2) acid cleaning and dipping, the obtained powder is dipped in strong acid solution and treated by gravity-floatation; 3) drying and roasting; 4) additive is evenly mixed. When in use, the compound scale inhibitor is not only can be mixed with limestone / lime solid material to be prepared into solution for synchronous adding, but also can be prepared into solution to be directly added into a desulfurizing tower. The invention has simple processing, saves the resources and reduces the preparation cost of the compound scale inhibitor; the compound scale inhibitor can improve the desulfurization degree, the utilization rate of absorbent and the reliability of system operation, while the desulphurization system is prevented from scale formation.

Owner:BAOSHAN IRON & STEEL CO LTD

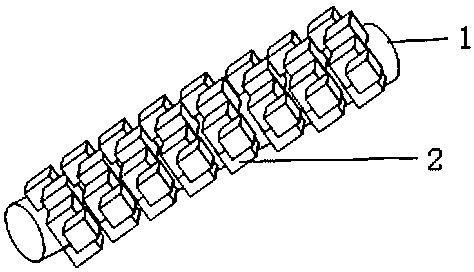

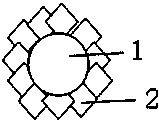

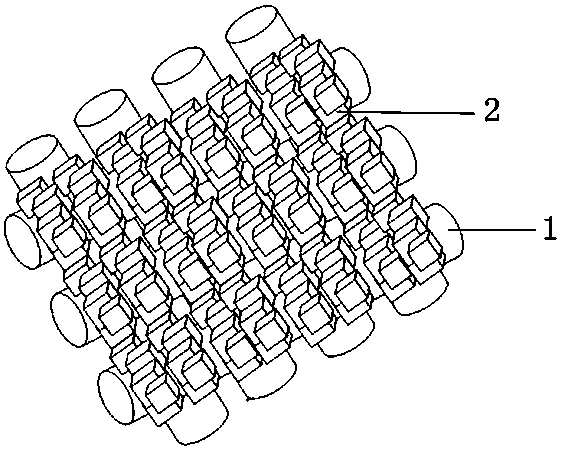

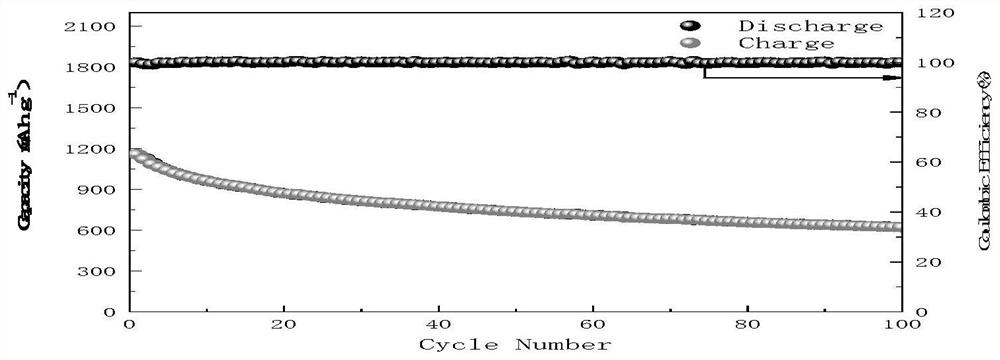

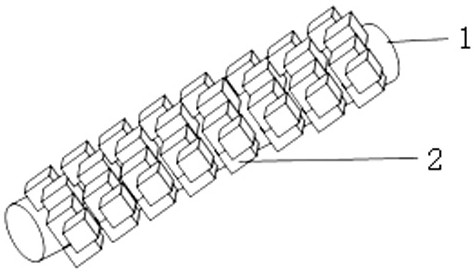

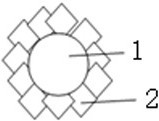

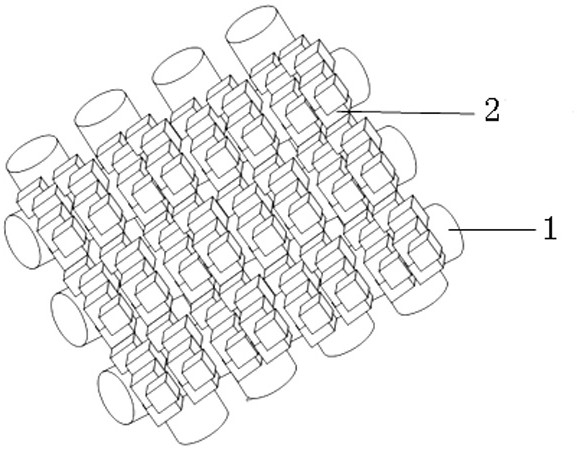

ZIF-9-based porous carbon/carbon fiber composite material and preparation method thereof

ActiveCN109192985AHigh porosityLarge specific surface areaMaterial nanotechnologyElectrode carriers/collectorsFiberPorous carbon

A ZIF-9-based porou carbon / carbon fiber composite material and preparation method thereof belongs to the technical field of a preparation method of a metal nanoparticle doped porous carbon / carbon fiber conductive composite material, can solve the problems of poor conductivity and poor stability of the existing composite carbon material, wherein the carbon fiber of a carbon fiber fabric is taken asa growth substrate, and high-density arranged ZIF is grown on the growth substrate; 9, carbonize at high temperature in an inert gas atmosphere to generate porous carbon / carbon fib composite material, and that invention realizes a ZIF-9-based porous carbon and conductive substrate integrated conductive network structure, lithium sulfide batteries, sodium sulfide batteries, lithium-air batteries and fuel cells, electrocatalysis and other fields have a wide range of applications.

Owner:清创人和生态工程技术有限公司

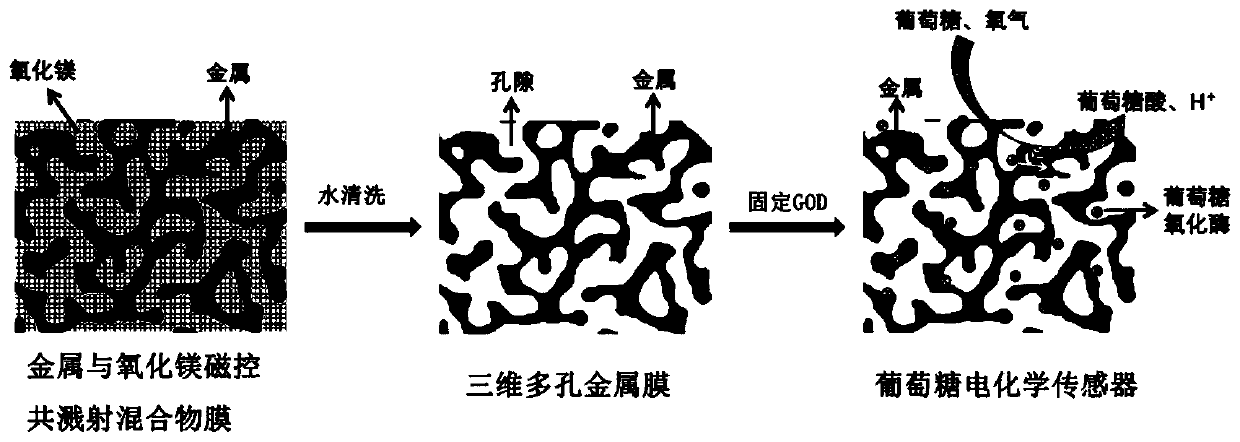

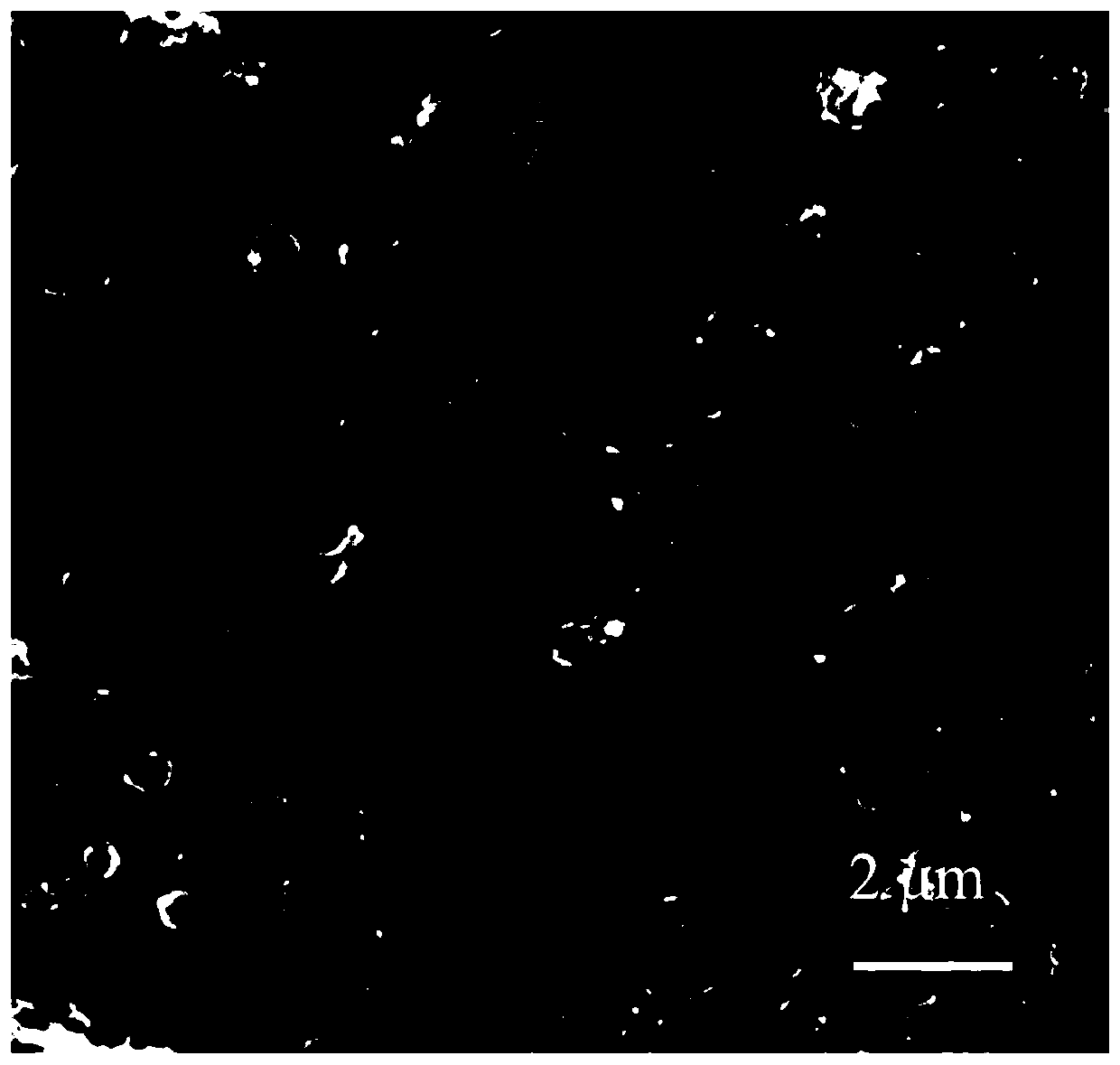

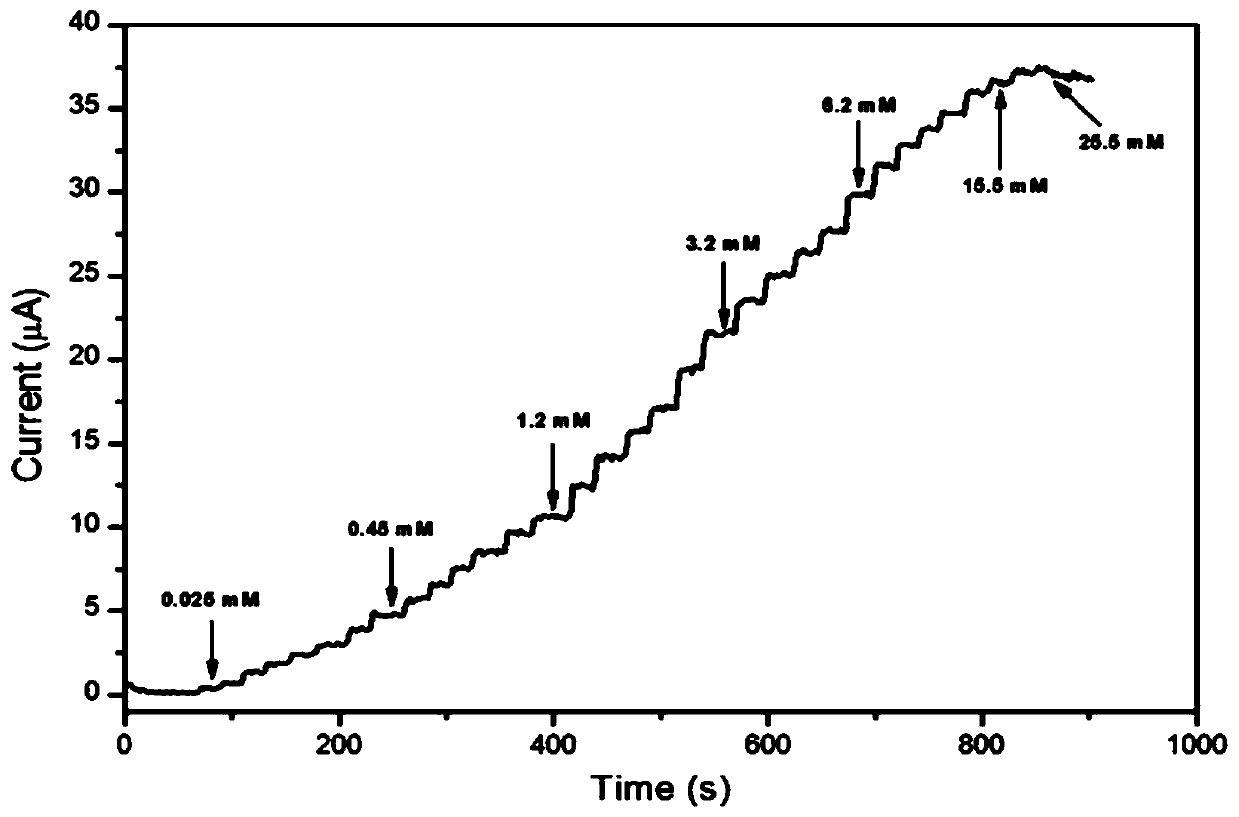

Glucose electrochemical microelectrode sensor based on nano porous metal film

PendingCN110618179AHigh sensitivityLarge linear rangeMaterial electrochemical variablesElectrochemistryPolymer

The invention discloses a preparation method of a nano porous metal film and a microelectrode sensor loaded with glucose oxidase (GOD) on the porous film for blood glucose monitoring, and relates to aprocessing technology of the porous metal film and a sensor technology. Metal and metal oxides of different proportions and thicknesses are subjected to magnetron co-sputtering on a polyimide substrate, treatment is conducted through deionized water or a weak acid solution to remove the metal oxides, metal layers which are each of a three-dimensional porous network structure and are interconnected are left to serves as a support layer and a conductive layer which are loaded with the GOD, the other side of the insulated substrate is coated with Ag / AgCl to serve as a reference-counter electrode, thus an electrochemical two-electrode system is constituted, then the substrate is coated with a high-molecular polymer to serve as a diffusion-limiting layer and an anti-interference hydrophilic layer, and then a glucose sensing microelectrode is constituted. The nano porous metal film is large in specific surface area, the active area of the electrode and the load amount of the GOD are effectively increased, permeability is good, conductivity is high, and physical damage to a microelectrode enzyme film sensing layer can be further prevented to a certain extent. The microelectrode sensor iswide in linear range and good in long-term stability.

Owner:ZHENGREN BEIJING MEDICAL INSTR CO LTD

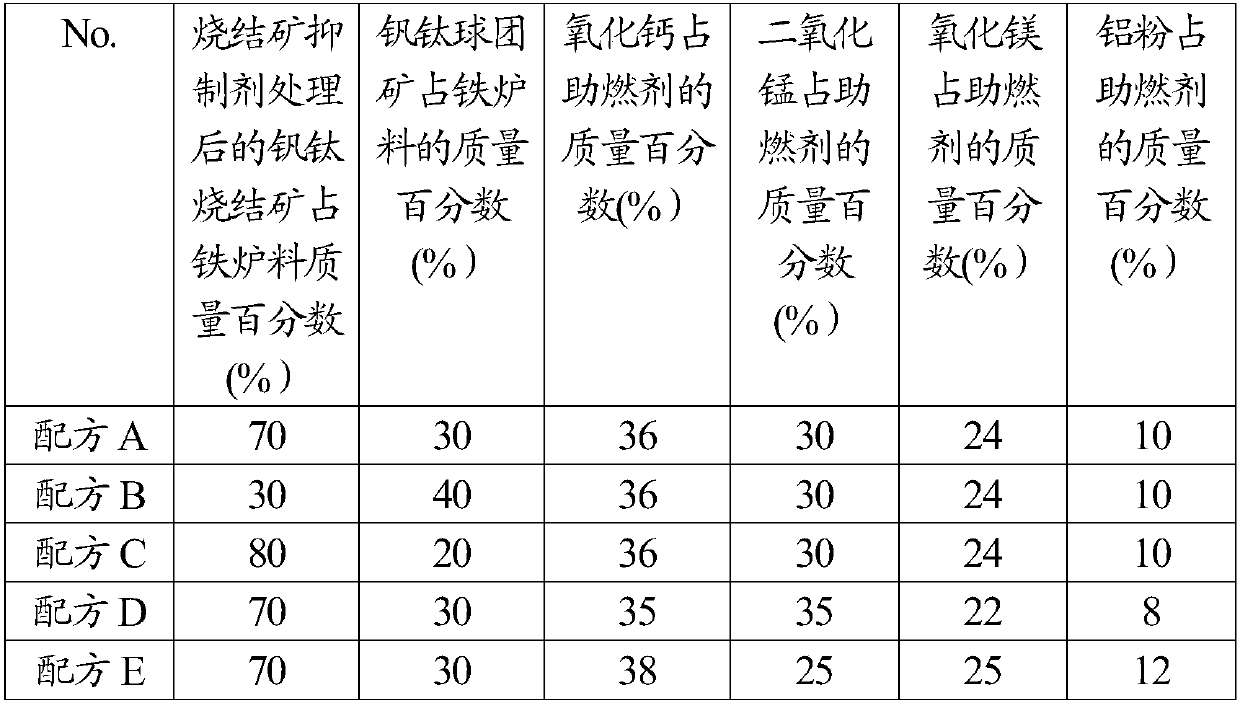

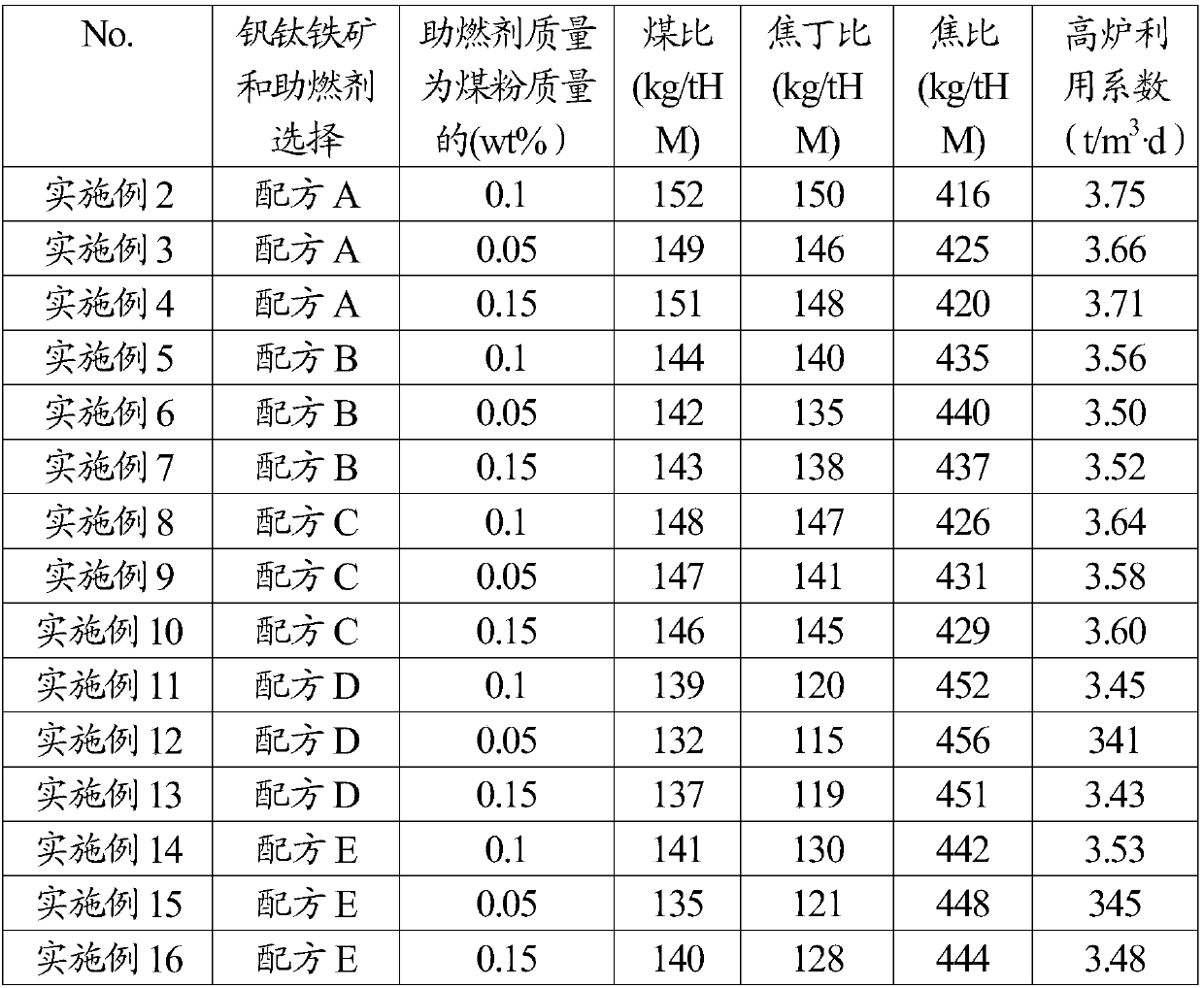

Blast furnace smelting method capable of lowering coke ratio and increasing coal ratio

InactiveCN107641670AEliminate internal stressReduce the pulverization rate of low temperature reductionBlast furnace detailsSmelting processBlast furnace smelting

The invention discloses a blast furnace smelting method capable of lowering coke ratio and increasing coal ratio. The blast furnace smelting method comprises the following steps: uniformly mixing vanadium-titanium sinter, vanadium-titanium pellets and coking ore processed by a sinter inhibitor to form an ore layer, wherein the vanadium-titanium sinter in the ore layer accounts for 60% to 80% of the total mass of iron furnace charge, and the vanadium-titanium pellets account for 20% to 40% of the total mass of the iron furnace charge; alternately distributing coke and the ore layer into a blastfurnace to form the alternate layer structure of the ore layer and the coke; mixing a combustion improver with pulverized coal to obtain a mixture; injecting the mixture into the blast furnace to becombusted; the combustion improver comprises 35% to 38% of calcium oxide, 25% to 35% of manganese dioxide, 22% to 25% of magnesium oxide and 8% to 12% of aluminum powder calculated in percentage by mass; the combustion improver accounts for 0.05 to 0.15% of the mass of coal calculated in percentage by mass; the technical indexes of the smelting process are that the coke ratio is 416 to 456 kg / tHM,the coking ratio is 115 to 150 kg / tHM, the coal ratio is 132 to 152kg / tHM, the blast temperature is 1150 to 1250 DEG C, and oxygen enrichment is greater than 2500m<3> / h; by adopting the blast furnacesmelting method, the coke ratio can be lowered, and the coal ratio and utilization coefficients of the blast furnace are increased.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

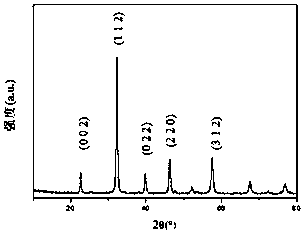

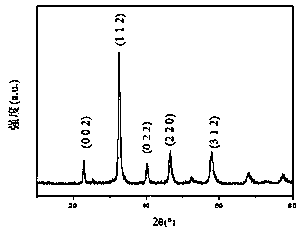

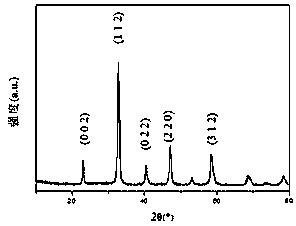

Preparation method of perovskite catalyst and product and application thereof

InactiveCN109092313AEasy accessEasy to operateHeterogenous catalyst chemical elementsElectrolytic organic productionCobalt metalCatalytic effect

The invention provides a preparation method of a perovskite catalyst and a product and an application thereof. The perovskite catalyst has a general formula LaFexCo1-xO3, wherein 0<x<1. The preparation comprises an iron metal precursor solution, a lanthanum metal precursor solution, a cobalt metal precursor solution, a palladium metal precursor solution and a citric acid solution. The method includes mixing the iron metal precursor solution, the lanthanum metal precursor solution, the cobalt metal precursor solution and the palladium metal precursor solution uniformly in a certain molar ratioand a certain mixing order; adding the citric acid solution to the uniformly mixed precursor solution; placing the mixture solution in an oven for drying to concentrate the mixture solution; keeping the temperature of the concentrated mixture at 700 DEG C for 4 hours in a muffle furnace to obtain the perovskite catalyst. The preparation method is simple and efficient, easy to operate and high in atomic utilization rate. The catalyst is applied to electrocatalysis to verify the catalytic effect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

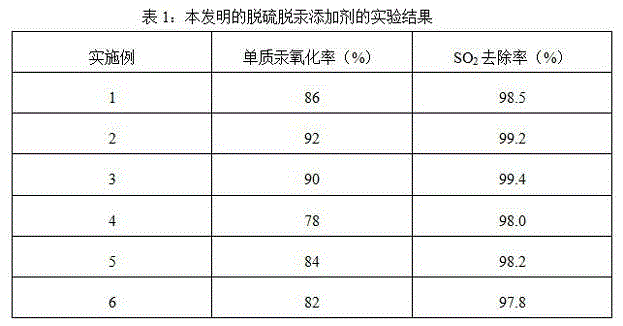

Additive capable of simultaneous desulphurization and demercuration and preparation method thereof

ActiveCN103143252AImprove desulfurization and mercury removal efficiencyReduce pollutionDispersed particle separationIron sulfatePhthalaldehyde

The invention discloses an additive capable of simultaneous desulphurization and demercuration. The additive comprises sodium benzoate, ferric sulfate, adipic acid and ortho-phthalaldehyde. The invention further discloses a preparation method for the additive capable of simultaneous desulphurization and demercuration. The additive can realize simultaneous desulphurization and demercuration, has high desulphurization and demercuration efficiency and has the advantages of improvement of activity of limestone, capacity of preventing fouling and blocking of a WFGD system and reduction of system energy loss.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Treatment technology for inner cavity surface of cylinder cover

ActiveCN104174570AImprove corrosion resistanceImprove high temperature resistancePretreated surfacesCoatingsCylinder headLaser scanning

The invention discloses a treatment technology for an inner cavity surface of a cylinder cover. The treatment technology comprises processes as follows: cleaning the inner cavity surface of the cylinder cover to remove oil and dust; preheating the inner cavity surface of the cylinder cover to 70-90 DEG C in a far-infrared heating manner; performing spraying: spraying paint onto the inner cavity surface of the cylinder cover, wherein the thickness of the coating is in a range of 60-90 mu m; performing drying: continuously keeping the temperature of the inner cavity surface of the cylinder cover in a range of 70-90 DEG C and continuously drying the coating for 5-10 min in the far-infrared heating manner; performing sintering: performing high-temperature sintering on the coating of the inner cavity surface of the cylinder cover in a laser scanning heating manner at the temperature of 190-200 DEG C for 20-25 min to form a corrosion-resistant high-temperature-resistant ceramic film layer on an inner cavity of the cylinder cover. The treatment technology has the advantages that the coating is high-temperature-resistant and corrosion-resistant and has a catalytic combustion effect, so that the combustion efficiency of an engine is improved.

Owner:福建力宝动力机械有限公司

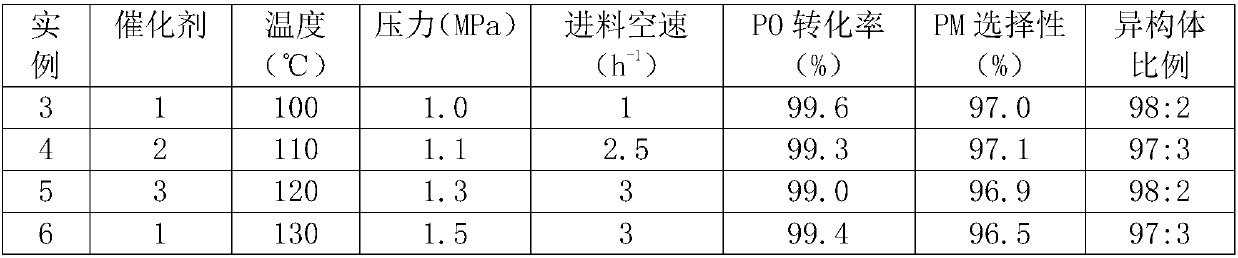

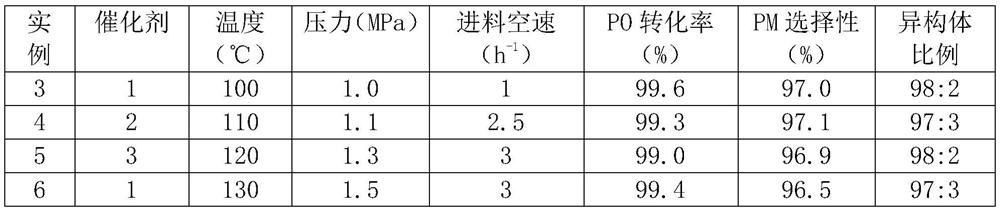

A preparation method of propylene glycol monoalkyl ether

ActiveCN109867589AIncrease alkalinityExtended service lifeEther preparation from oxiranesMetal/metal-oxides/metal-hydroxide catalystsAlcoholEther

The invention discloses a preparation method of propylene glycol monoalkyl ether. Propylene oxide and alcohol are used as raw materials and react under the catalysis of a modified magnetic solid basecatalyst to prepare the propylene glycol monoalkyl ether. The catalyst is obtained by taking nickel ferrite as a magnetic core, magnesium-aluminum oxide as a carrier and cesium as an active componentthrough transition metal modification. The method improves the reaction activity and selectivity, and alleviates the operation conditions; and the catalyst is long in service lifetime, easy to recoverand regenerate and low in production product, overcomes various defects in the prior art, and can be used for industrial production.

Owner:WANHUA CHEM GRP CO LTD

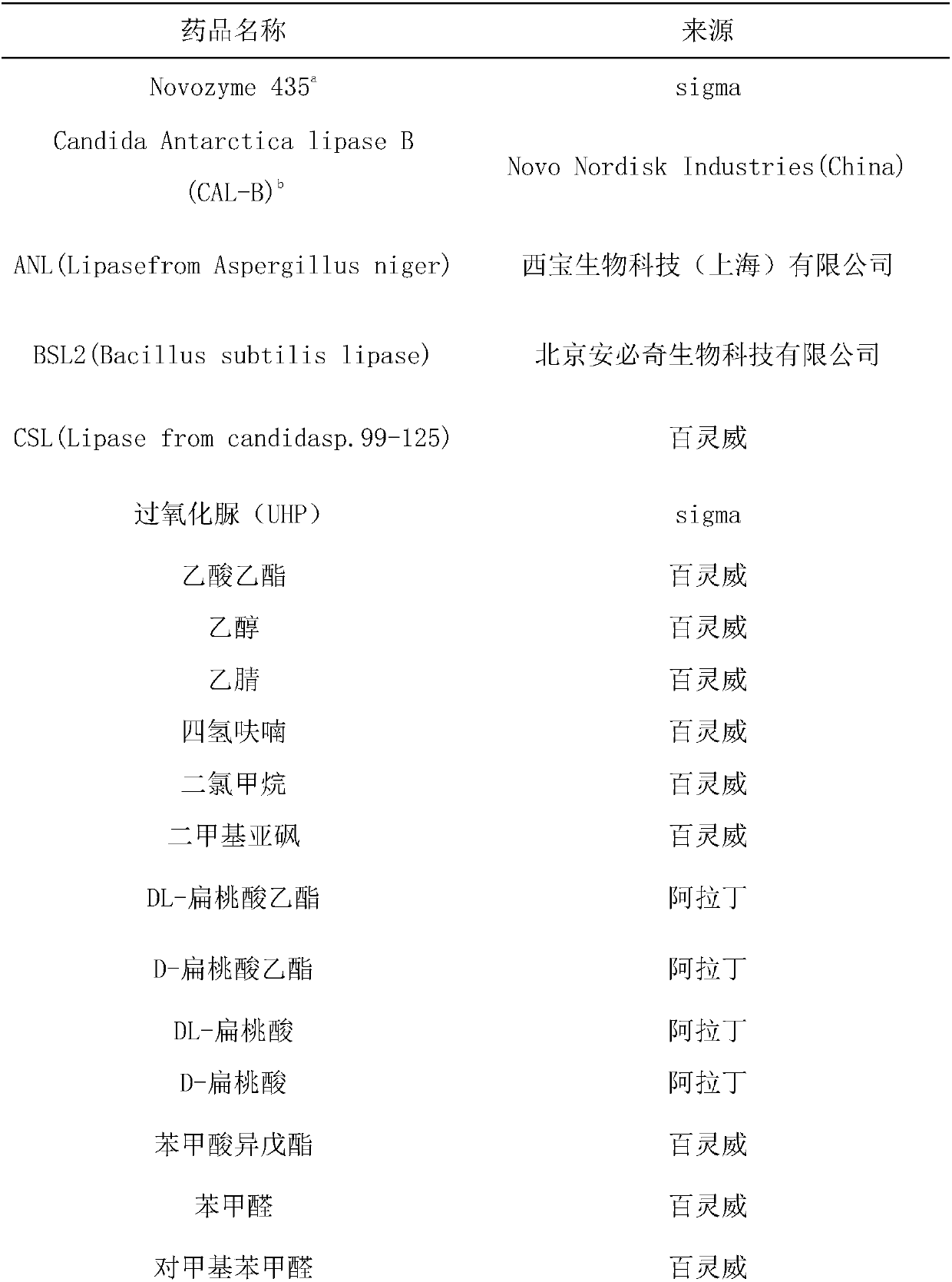

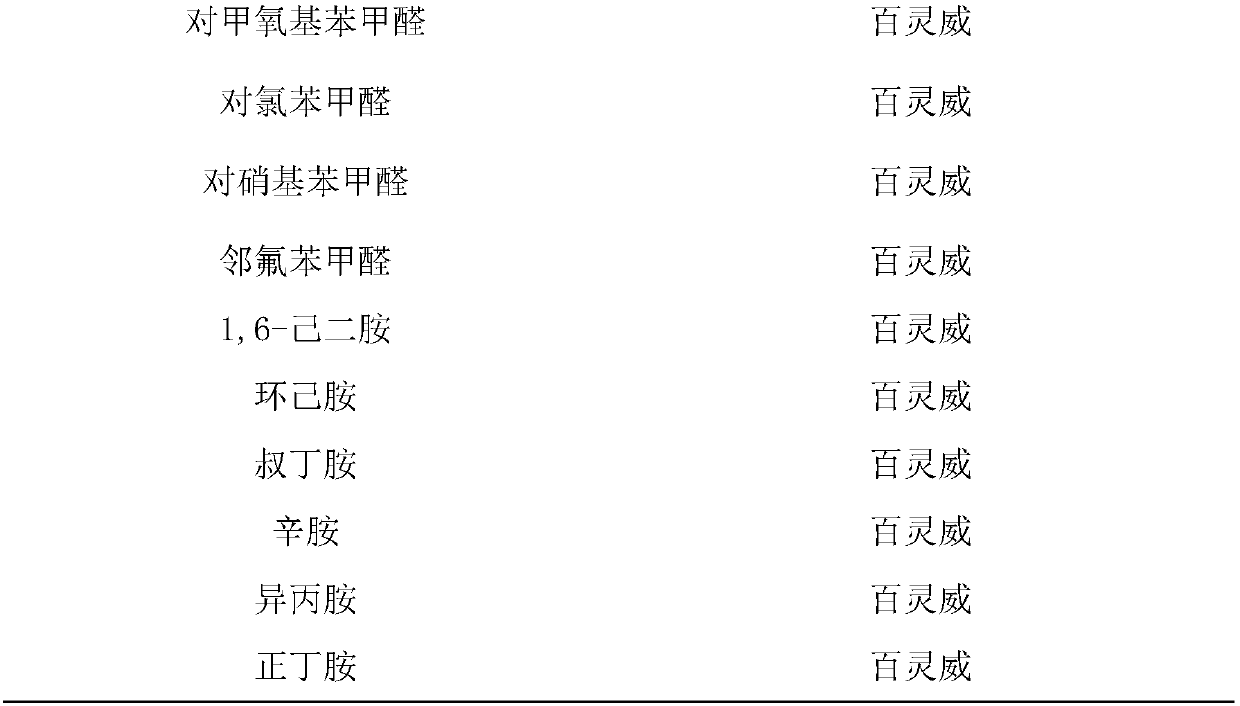

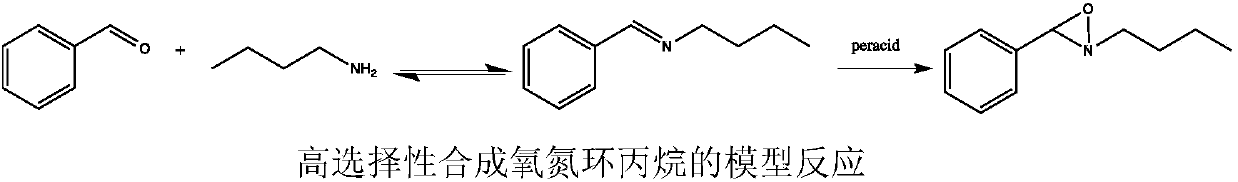

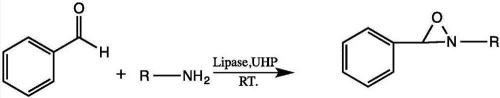

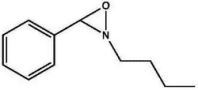

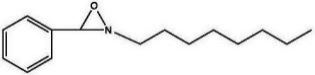

Method for synthesizing high-selectivity oxaziridine through chemical enzyme process

ActiveCN107739741AHas a catalytic effectNo useFermentationEnvironmental resistanceChemical synthesis

The invention discloses a method for synthesizing high-selectivity oxaziridine through a chemical enzyme process and belongs to the technical field of chemical synthesis. According to the method, aromatic aldehyde and fatty amine are used as reaction substrates, acetonitrile is used as a solvent and D-ethyl mandelate is used as a peroxy-acid precursor. The method comprises the following operationsteps: adding enzyme, an oxidizing agent, the reaction substrates, the peroxy-acid precursor and the solvent into a reaction container, stirring and reacting for 2 hours under the room-temperature condition to obtain the high-selectivity oxaziridine. The experiment proves that lipase has an obvious catalyzing effect of the reaction and can reach high cis-trans selectivity which is greater than 90%or more; no by-product is generated in the reaction process. Compared with the conventional chemical synthesis method, the method has the advantages of metal-free catalysis, green and environmental protection, low cost, high efficiency and high selectivity; a new method is provided for synthesizing oxaziridine compounds with cis-trans selectivity.

Owner:JILIN UNIV

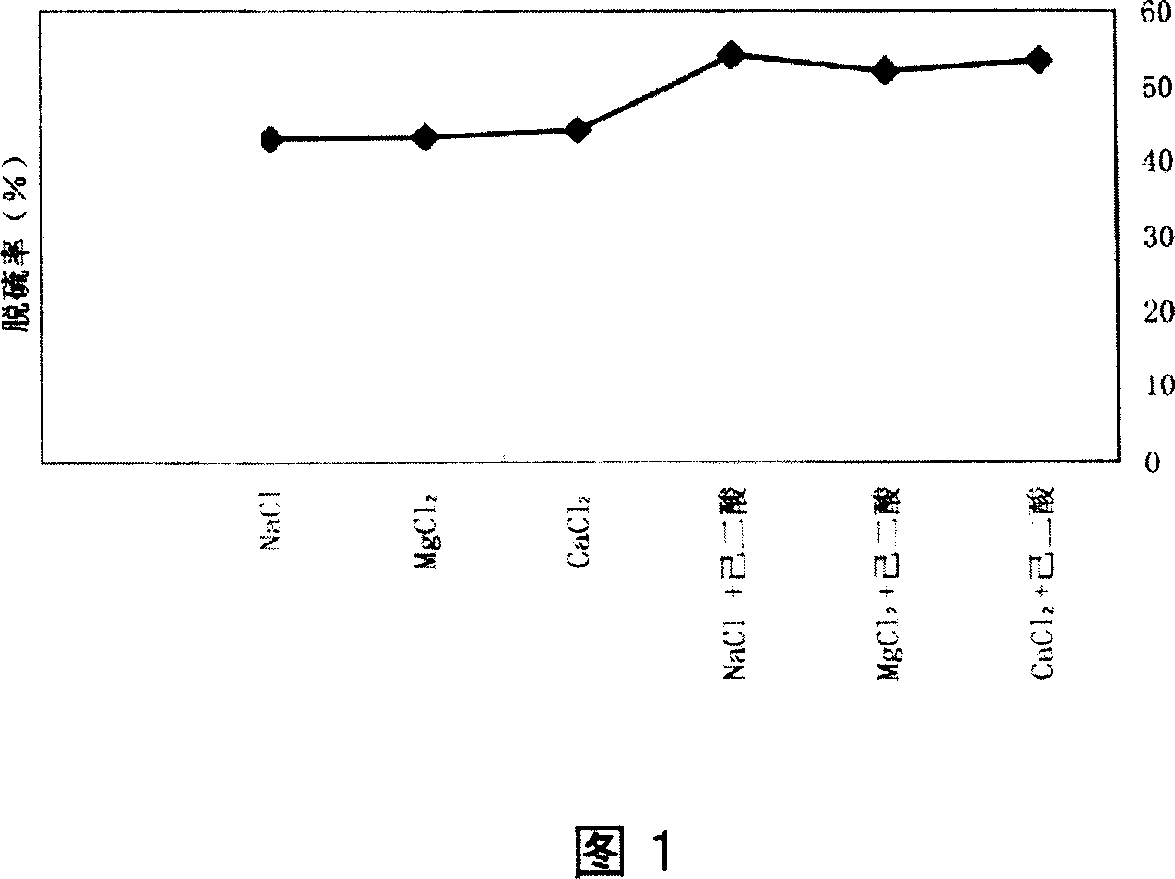

Method for reinforcing lime stone slurry activity in smoke desulfurizing process and combined additive

The present invention relates to method of reinforcing limestone slurry activity in fume desulfurizing process and the combined additive. Into limestone slurry, two kinds of matter are added, including adipic acid in 1000 + / -15%mg / L and chlorine salt in (1000-3000) + / -15%mg / L, with the weight ratio between adipic acid and chlorine salt being 1 to 1-3, and the chlorine salt being NaCl, MgCl2 or CaCl2. The present invention has reaction catalyzing effect to raise the reaction activity by over 50 %, and is favorable to the dissolving of gas and the creation of solid product in desulfurizing reaction. It has also 10 % raised desulfurizing rate, lowered limestone consumption, reduced slag amount, lowered operation cost and raised system operation flexibility, and may be applied in fume desulfurizing limestone / lime-gypsum process for thermal power plant.

Owner:国能朗新明环保科技有限公司

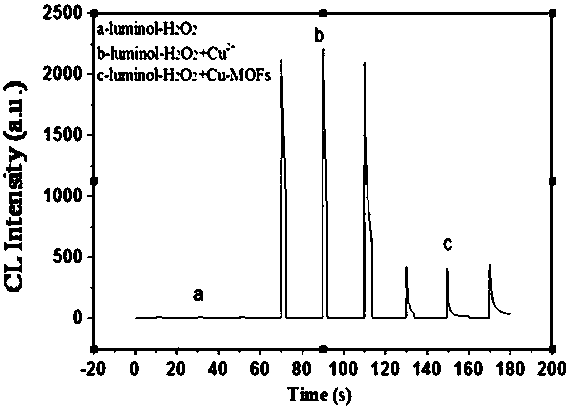

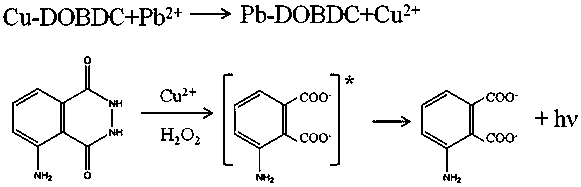

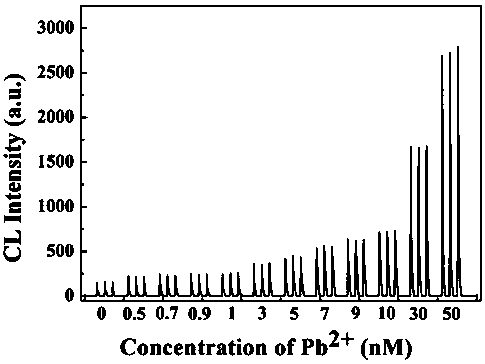

Method for detecting Pb < 2 + > by Cu-MOF-luminol-H2O2 chemiluminescence system

ActiveCN111474167AHas a catalytic effectEnhanced chemiluminescenceChemiluminescene/bioluminescencePreparing sample for investigationReactive siteLuminol chemiluminescence

The invention discloses a method for detecting Pb < 2 + > by a Cu-MOF-luminol-H2O2 chemiluminescence system, belongs to the field of chemical detection, and can solve the problems that the existing detection method has low sensitivity and is not suitable for detection of trace or even lower-concentration lead ions and has high requirements on detection equipment in the prior art. Cu-DOBDC is obtained from a divalent metal ion Cu (II) and an organic ligand 2, 5-dihydroxy terephthalic acid (H2DOBDC) by using a hydrothermal method, and is introduced into a luminol-H2O2 chemiluminescence system toform the Cu-DOBDC-luminol-H2O2 chemiluminescence system. When Pb < 2 + > exists, Pb < 2 + > and Cu-DOBDC have stronger coupling capacity, Cu at an active site in Cu-DOBDC is released, chemiluminiscence of a luminol-H2O2 system is enhanced, and the signal enhancement degree is in direct proportion to the concentration of Pb < 2 + >. The method is easy to operate, high in sensitivity, low in detection limit, high in selectivity and suitable for on-site rapid detection.

Owner:中晋环境科技有限公司

Method for producing molecular sieve by fly ash and molecular sieve prepared thereby

InactiveCN108298555AReduce manufacturing costImprove the effect of adsorption and purificationFaujasite aluminosilicate zeoliteVacuum dryingAdsorption effect

The invention relates to a method for producing molecular sieve by fly ash and a molecular sieve prepared thereby. The molecular sieve is prepared from the following raw materials in parts by weight:60-70 parts of fly ash, 20-30 parts of a nano negative ion powder, 8-12 parts of plant ash, 5-8 parts of caustic soda, 8-12 parts of water glass, 15-25 parts of a cold catalyst liquid and 30-60 partsof water. The fly ash is subjected to magnetic separation, roasting and cooling pretreatment, then mixed and stirred with other solid raw materials and liquid raw materials, next subjected to crystallization treatment by a thermal autoclave, and subjected to vacuum negative pressure drying and molding in a vacuum drying oven, and thus the molecular sieve is obtained. With the fly ash as the main raw material, the construction cost is low, the raw materials are sufficient, the solid waste fly ash resources is effectively utilized, secondary utilization of the resources is achieved, the environmental pollution caused by the accumulation of fly ash is also avoided, and he prepared molecular sieve has the inner crystal surface highly polarized and has good adsorption effect.

Owner:LIUZHOU LIUJING TECH CO LTD

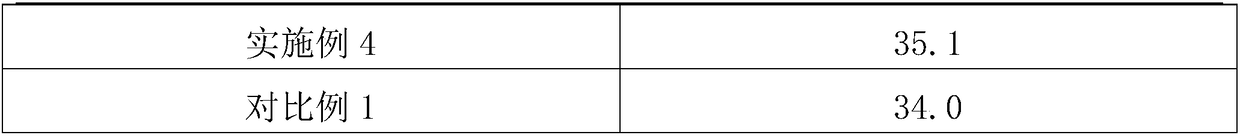

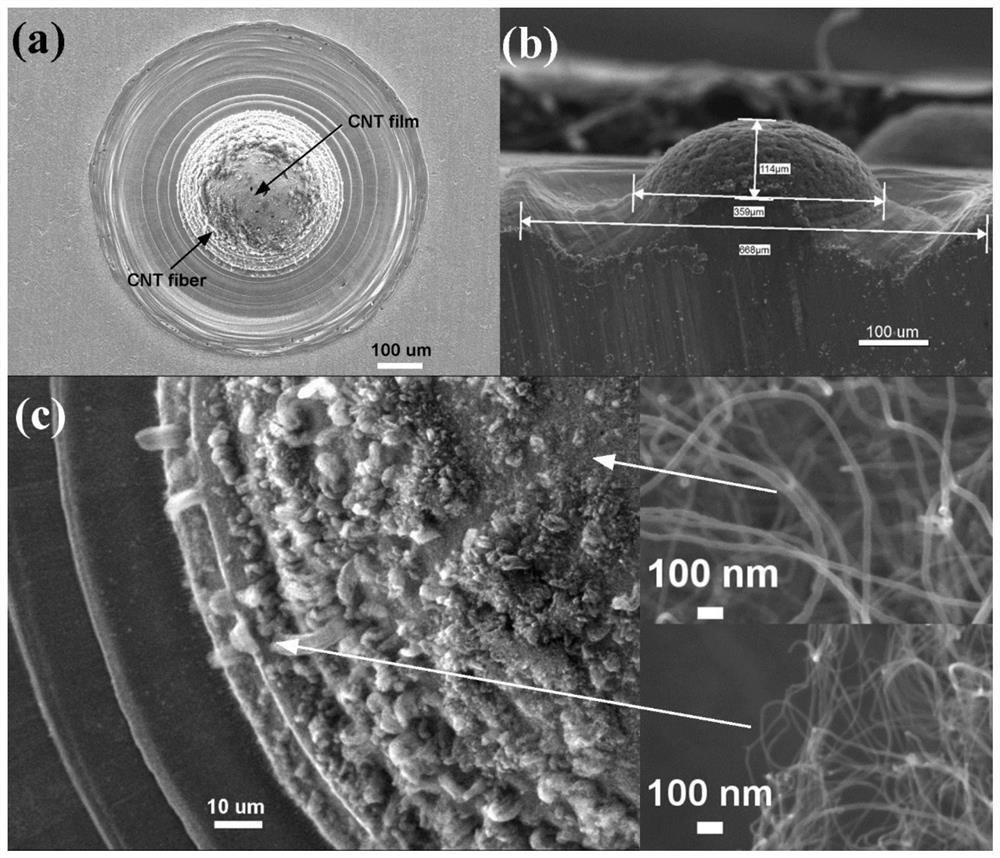

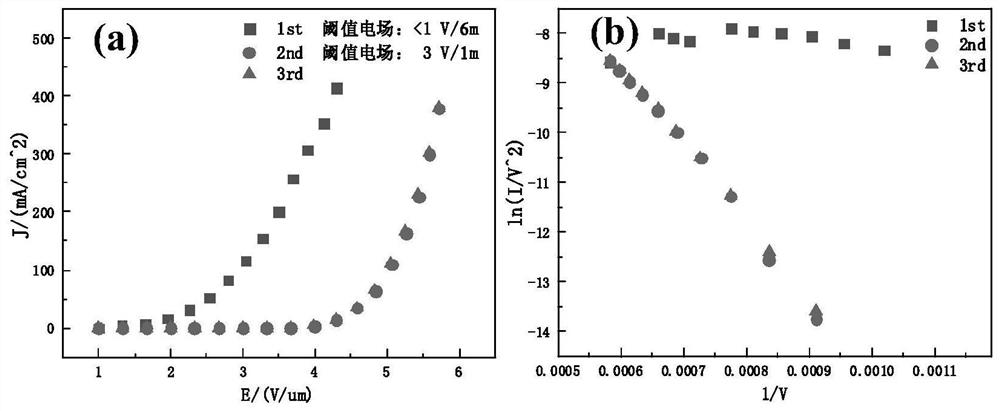

Microfocus field emission electron source based on carbon nanotubes and preparation method thereof

ActiveCN113380597AHas a catalytic effectReduce the turn-on electric fieldElectric discharge tubesCold cathode manufactureHigh current densityChemical physics

The invention discloses a microfocus field emission electron source based on a carbon nanotube and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: (1) plating a metal platinum layer on the surface of a nickel substrate; (2) under the protection of protective gas, performing point ablation on the surface of the nickel substrate plated with metal platinum by using pulse laser in a negative defocusing mode, wherein the laser focus is in the nickel substrate during negative defocusing ablation, so that internal nickel metal is molten, and the molten nickel metal flows to the surface of the nickel substrate under the pushing action of nickel metal steam and is cooled to form a spherical shell; and (3) directly growing a carbon nanotube cathode film on the spherical shell formed by laser ablation of the nickel substrate by using a chemical vapor deposition method. According to the invention, the microfocus electron source has the advantages of low starting electric field (less than 1V / [mu] m), high current density (about 1A / cm<2>), good high-pressure emission working stability and the like.

Owner:WENZHOU UNIVERSITY

Novel microwave-based cement production method capable of generating power with waste gas

The invention relates to a novel microwave-based cement production method capable of generating power with waste gas. The method comprises the following steps: S1: mixing; S2: forming; S3: combustion and decomposition; S4: power generation with waste gas; S5: tail gas treatment; and S6: cooling and feeding. The microwaves are utilized for heating, thereby enhancing the calcination decompose work efficiency; and the decomposed waste gas is recycled to generate power, thereby performing the functions of lowering the cost and protecting the environment.

Owner:南京戈德水泥技术工程有限责任公司

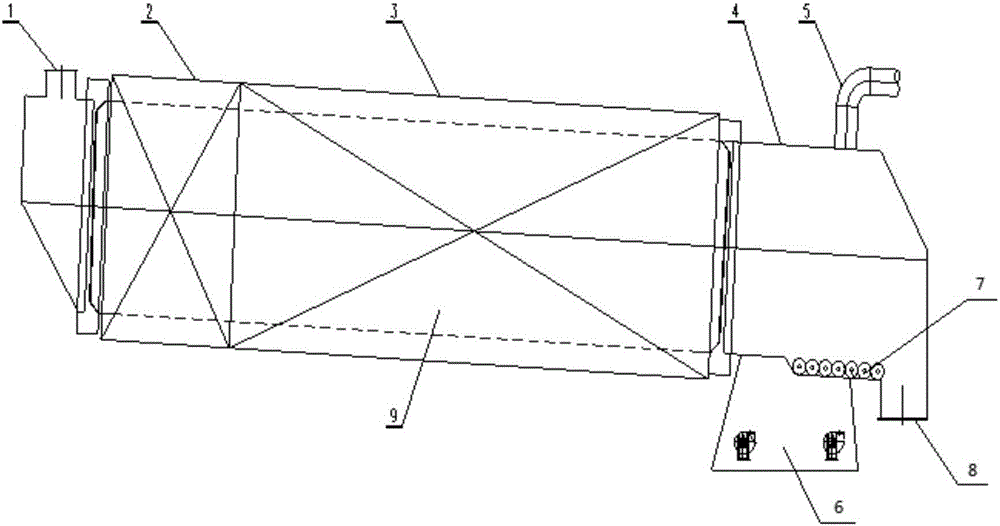

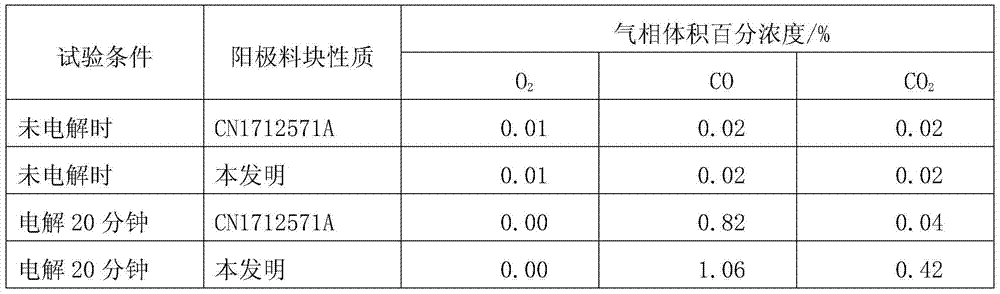

Preparation method of composite anode during electrolytic extraction of titanium metal

The invention relates to a method for producing metal by molten salt electrolytic metallurgy, in particular to a method for extracting metal titanium by molten salt electrolysis, and in particular to a method for preparing a composite anode when electrolytically extracting metal titanium. The method of the present invention comprises the following steps: a, raw material preparation: measuring the titanium content M in the titanium liquid obtained in the process of producing titanium white by the sulfuric acid method; b, mixing composite anode materials: adding a reducing agent and viscose to the titanium liquid obtained in step a binder, rinsing to obtain a uniformly mixed mixed material; c, preparation of composite anode: press the mixed material under a pressure of 0.5 to 1.5 MPa, dry, and calcinate to obtain a titanium-containing composite anode; d, preparation of metal titanium: The titanium-containing composite anode is used as the battery anode, carbon steel is used as the cathode, and metal titanium is obtained on the battery cathode according to the molten salt electrolysis method. The method for preparing the anode material is simple, the energy consumption is low, and the reaction rate of the anode material is fast.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for improving glass feeling of surface of diammonium phosphate

InactiveCN109279976AVisibly crystal clearStrong sense of glassAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiammonium phosphatePhosphoric acid

The invention discloses a method for improving glass feeling of the surface of diammonium phosphate. The method comprises the following steps that in a conventional method for producing diammonium phosphate by using phosphoric acid, boric acid which accounts for 0.05-0.20% by mass of the phosphoric acid in a neutralization tank is added into the neutralization tank, wherein the boric acid is a weak acid. The method disclosed by the invention is mainly used for improving performance such as transparency, luster, strength and the like of diammonium phosphate particles, and meanwhile, diammoniumphosphate can contain boron microelements, has fertilizer efficiency to many crops, can improve the crop quality and increase the yield, and also has insecticidal and catalyst effects.

Owner:HUBEI FORBON TECH

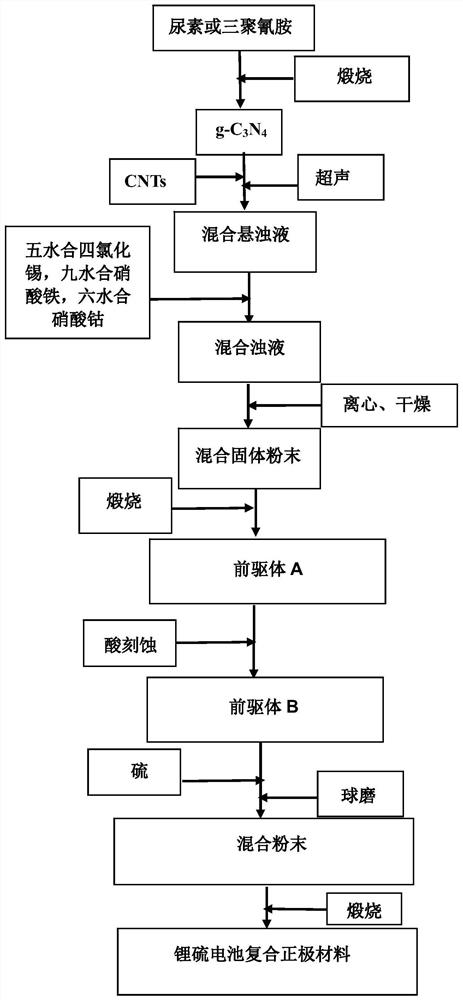

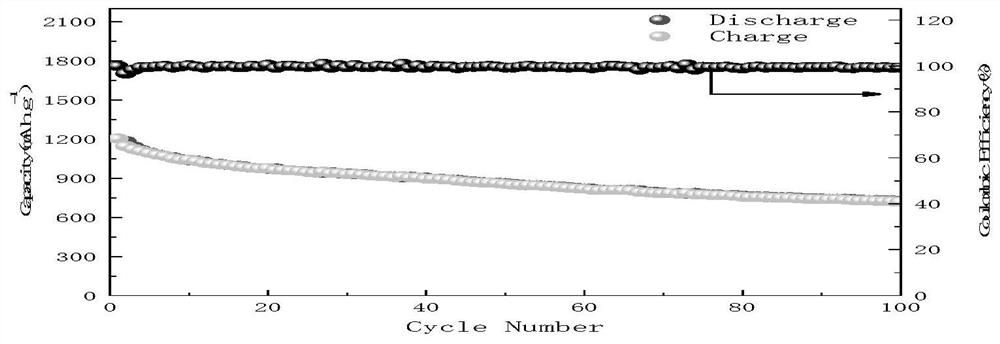

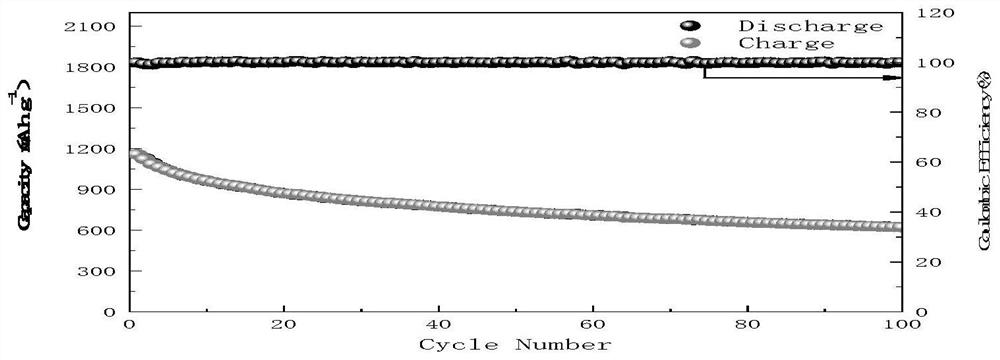

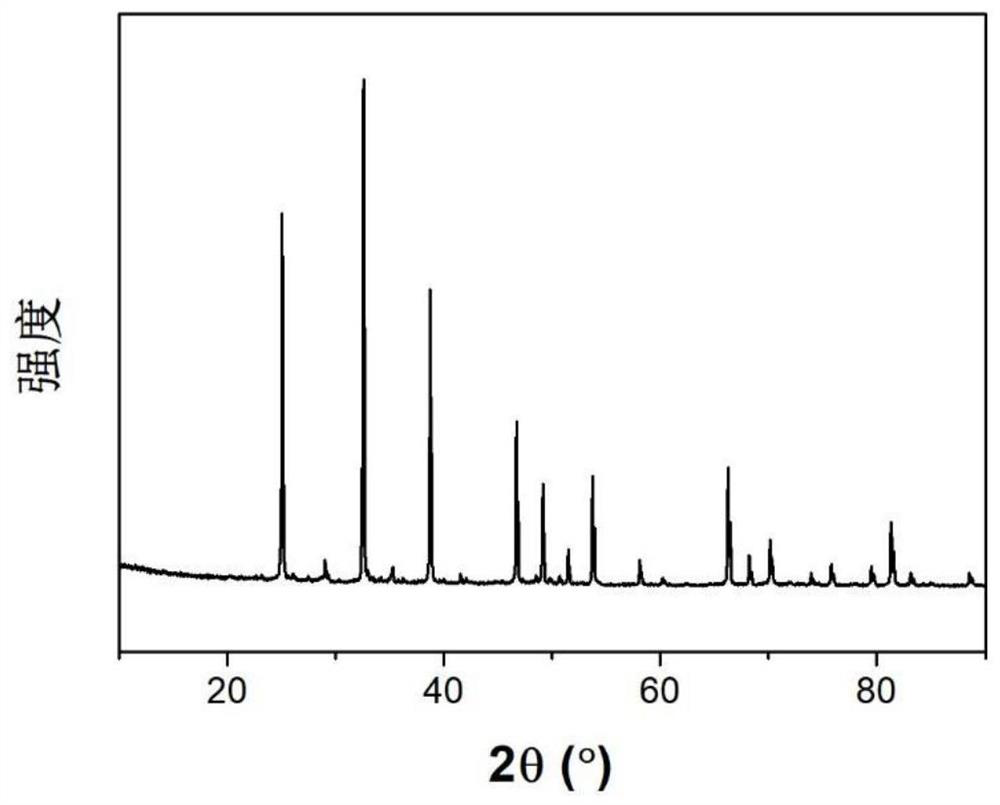

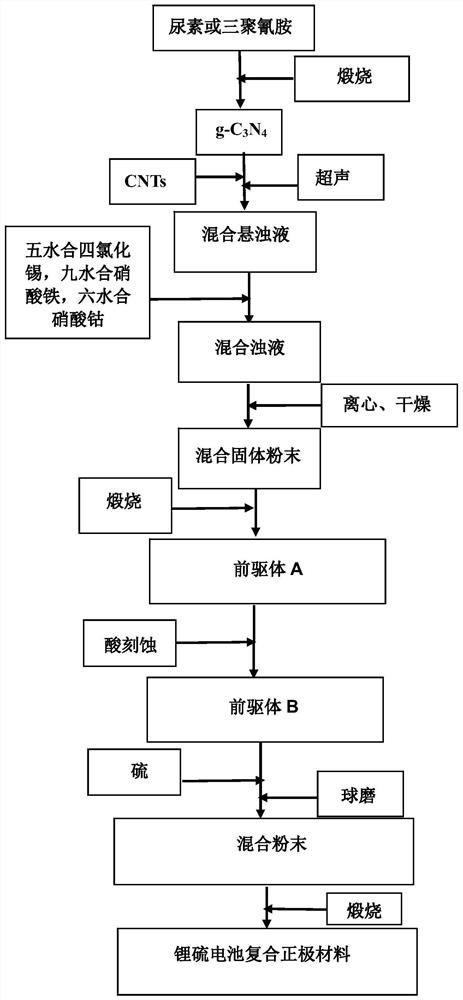

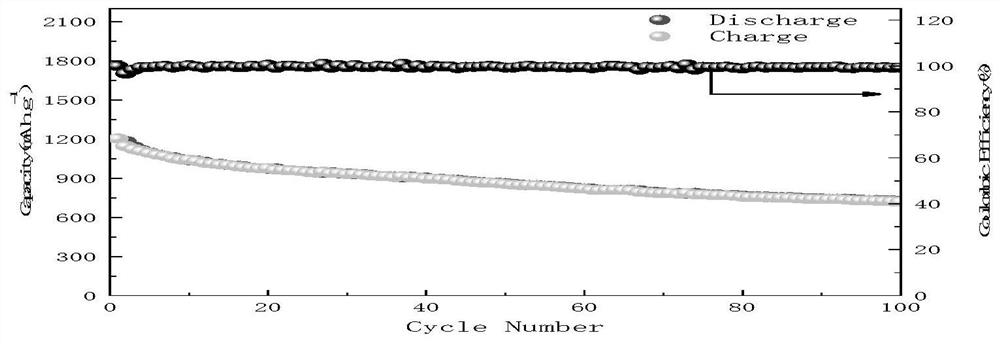

Preparation method of lithium-sulfur battery composite positive electrode material

ActiveCN113471421APrevent oxidationImprove protectionPositive electrodesLi-accumulatorsAcid etchingElectrical battery

The invention belongs to the technical field of lithium-sulfur battery preparation, and particularly relates to a preparation method of a lithium-sulfur battery composite positive electrode material. The preparation method comprises the following steps: dispersing g-C3N4 and carbon nanotubes in deionized water to obtain a mixed suspension; dissolving tin tetrachloride pentahydrate, ferric nitrate nonahydrate and cobalt nitrate hexahydrate in deionized water to obtain a mixed solution; stirring, mixing and reacting the mixed solution and the mixed turbid liquid to obtain a precipitate; drying and calcining the precipitate to obtain a precursor A; performing acid etching on the precursor A to obtain a precursor B; mixing the precursor B with sulfur, and carrying out ball milling to obtain mixed powder; and calcining the mixed powder to obtain the lithium-sulfur battery composite positive electrode material. Based on the defect of electrochemical performance of a single doped material of the lithium-sulfur battery, the SnO2 template and the g-C3N4 frame are creatively doped with the raw material of the lithium-sulfur battery at the same time, so that the battery performance is greatly improved.

Owner:SHANDONG UNIV OF TECH

Preparation method of rare earth sulfide pigment

ActiveCN113415818AThe synthesis process is simpleLow equipment requirementsRare earth metal sulfidesRare earth metal compounds preparation/treatmentPhysical chemistryProcess engineering

The invention discloses a preparation method of a rare earth sulfide pigment, which comprises the following steps: carrying out high-temperature solid-phase reaction on zinc sulfide as a sulfur source and rare earth oxide in a reducing atmosphere to obtain rare earth sulfide powder. The preparation steps are simple, toxic, flammable and explosive vulcanizing agents such as H2S, CS2 or elemental sulfur powder are not used, and the preparation method is a green preparation method suitable for the rare earth sulfide pigment.

Owner:HUNAN NORMAL UNIVERSITY

Flue gas desulfurization additive

ActiveCN102114385BHigh reactivityReduce consumptionDispersed particle separationDissolutionSilicon dioxide

The invention discloses a flue gas desulfurization additive, and relates to a desulfurization additive added into a wet desulfurization absorbent. The desulfurization additive consists of the following components in percentage by weight: 22 to 26 percent of sodium carbonate, 19 to 22 percent of aluminum sulfate, 12 to 17 percent of ferric oxide, 16 to 19 percent of aluminum oxide, 4 to 6 percent of sodium carboxymethylcellulose, 14 to 16 percent of silicon dioxide micropowder, and 3 to 5 percent of sodium polyacrylate. The desulfurization additive is favorable for dissolution of gas and generation of solid products in a limestone desulfurization reaction, has reaction catalysis effect at the same time, and increases the reaction activity of limestone by over 50 percent; and the desulfurization additive improves the desulfurization rate of a wet desulfurization process, shortens the time of the desulfurization reaction, improves the desulfurization efficiency by over 20-25 percent, reduces the consumption of the limestone, reduces residue amount, and lowers operation cost.

Owner:洛阳万山高新技术应用工程有限公司

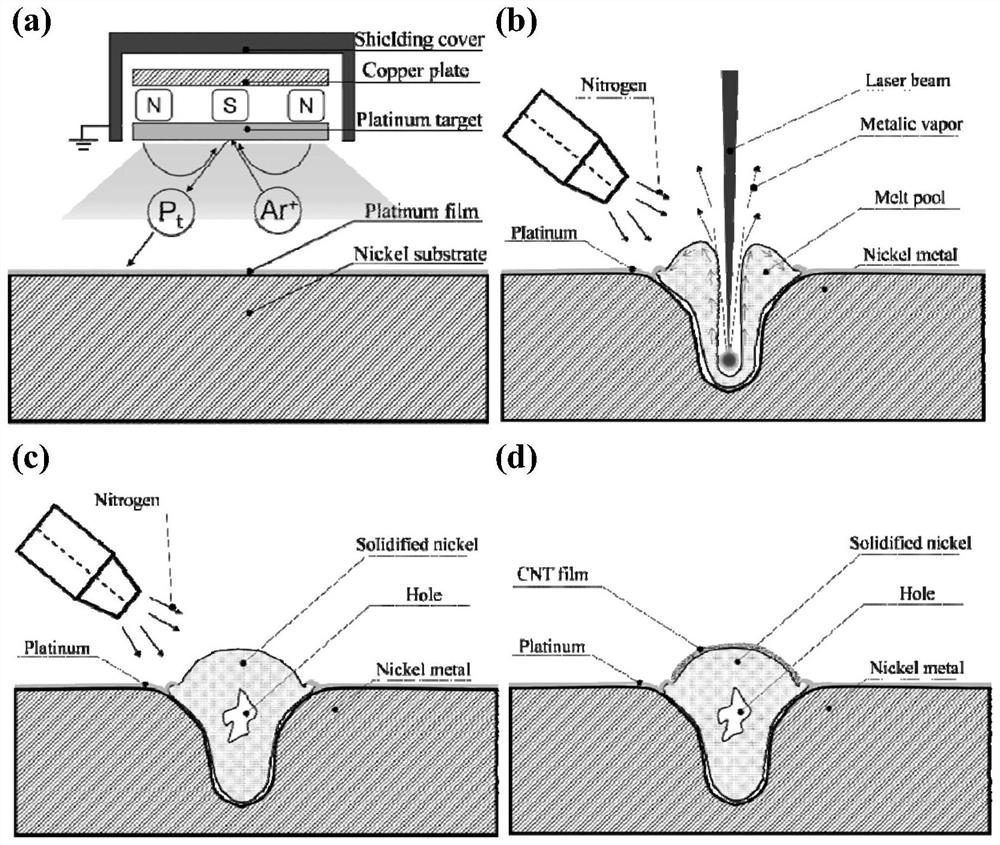

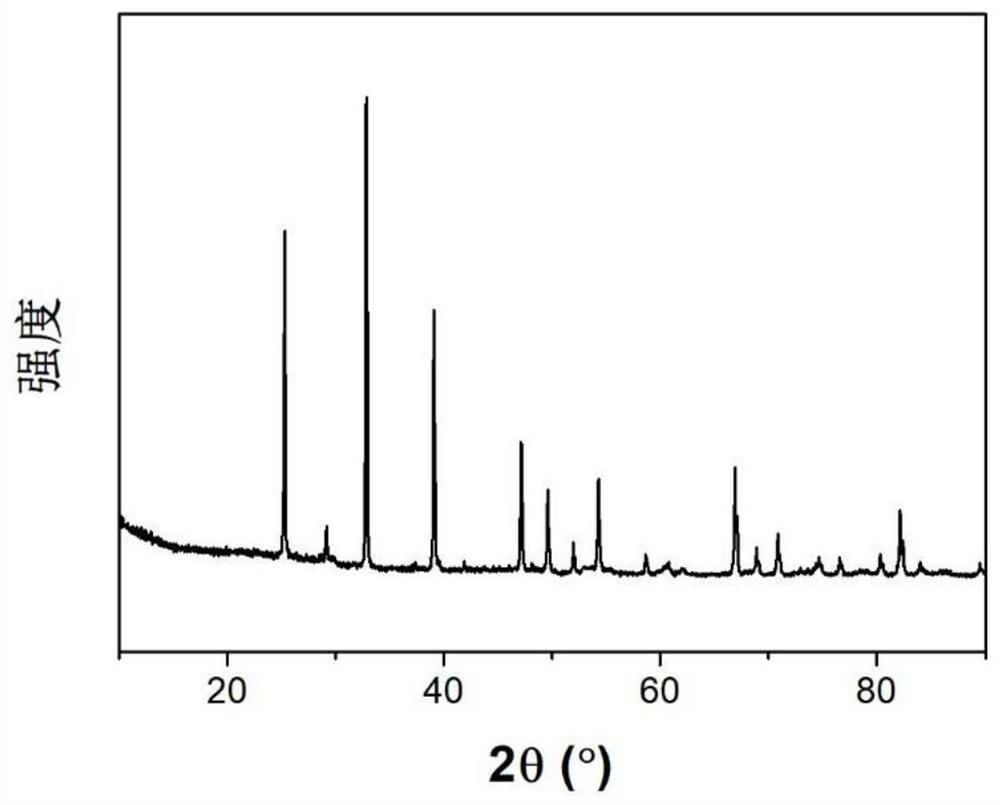

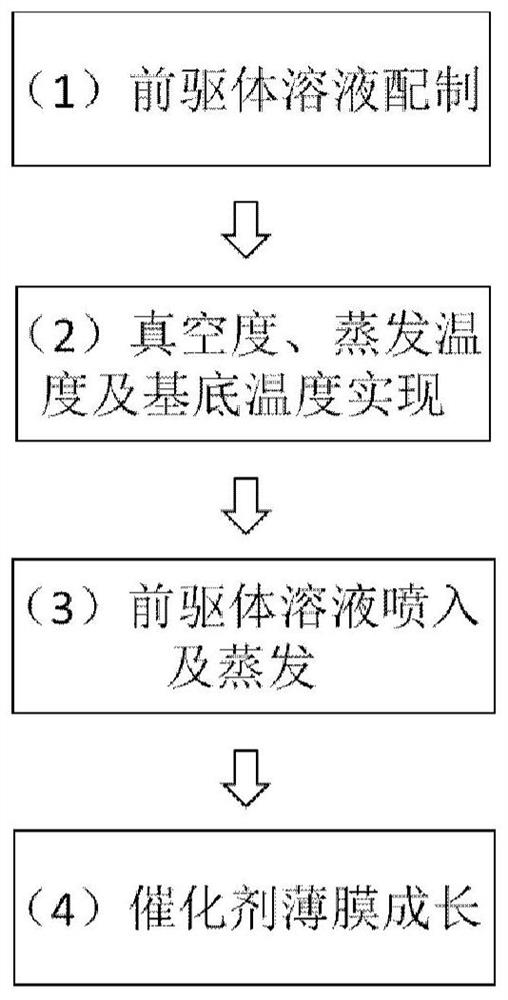

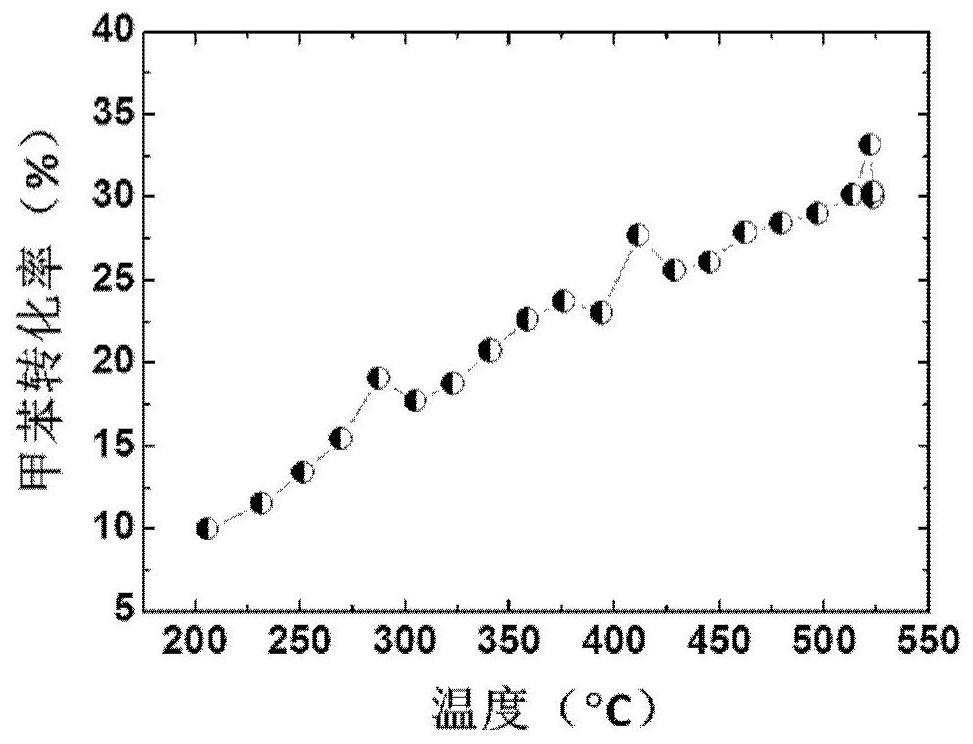

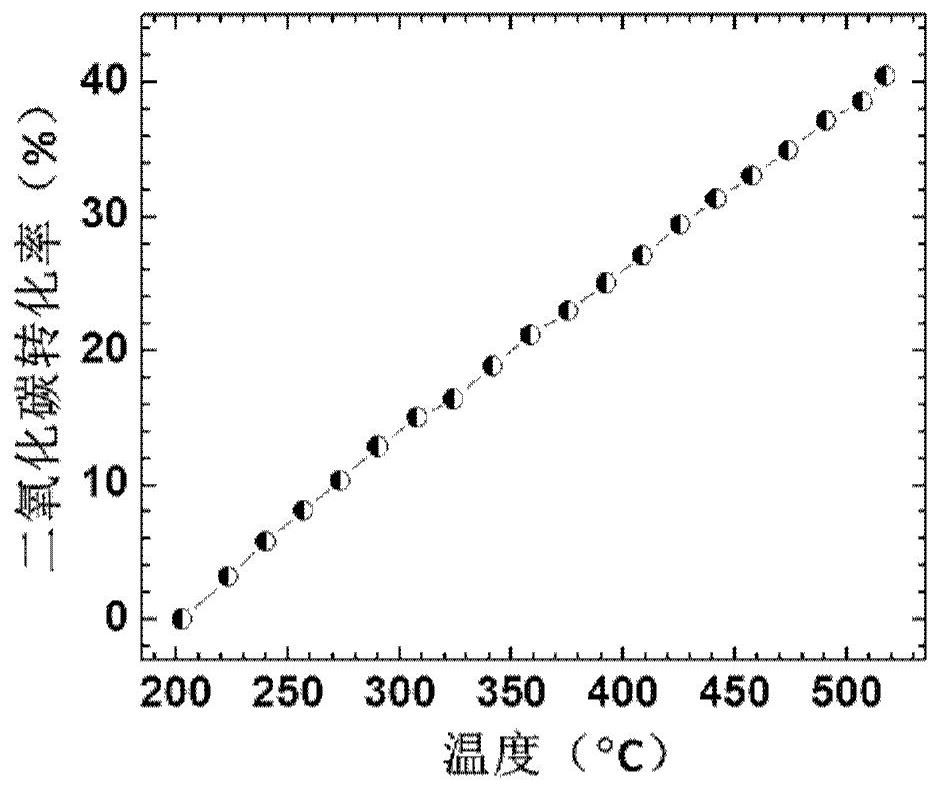

Ternary metal oxide thin film catalyst and preparation method thereof

ActiveCN109513445BTwo-way catalytic function hasPlay a catalytic roleGas treatmentHeterogenous catalyst chemical elementsMischmetalPtru catalyst

A ternary metal oxide thin film catalyst and a preparation method thereof, the catalyst includes a substrate and a ternary metal oxide thin layer deposited on the substrate, wherein the ternary metal oxide thin layer contains three metal oxides, each independently Oxides selected from noble metals, transition metals or rare earth metals can be prepared specifically by pulse atomization thermal evaporation chemical vapor deposition. The invention not only can catalyze the oxidative removal of volatile organic pollutants, but also has a certain catalytic effect on the hydrogenation conversion of carbon dioxide, and a relatively large catalyst specific surface area can be obtained with a small amount of catalyst, which is beneficial to the progress of the catalytic reaction.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Use of magnesium used refractory, preparation and use method of composite scale inhibitor

ActiveCN101396634BReduce manufacturing costWide adaptabilityDispersed particle separationTreatment using complexing/solubilising chemicalsSlagRefractory

The invention discloses a usage of magnesium used refractory material as well as the preparation and using method of a compound scale inhibitor, and is characterized in that the magnesium used refractory material which is the waste of industry is used for preparing the compound scale inhibitor. The method for preparing the compound scale inhibitor comprises the steps: 1) the magnesium used refractory material which is the waste of industry is sequentially treated by sorting, removing slag and chilled steel, grounding processing, magnetic separation and removal of iron as well as multilevel grounding, and then made into powder; 2) acid cleaning and dipping, the obtained powder is dipped in strong acid solution and treated by gravity-floatation; 3) drying and roasting; 4) additive is evenlymixed. When in use, the compound scale inhibitor is not only can be mixed with limestone / lime solid material to be prepared into solution for synchronous adding, but also can be prepared into solution to be directly added into a desulfurizing tower. The invention has simple processing, saves the resources and reduces the preparation cost of the compound scale inhibitor; the compound scale inhibitor can improve the desulfurization degree, the utilization rate of absorbent and the reliability of system operation, while the desulphurization system is prevented from scale formation.

Owner:BAOSHAN IRON & STEEL CO LTD

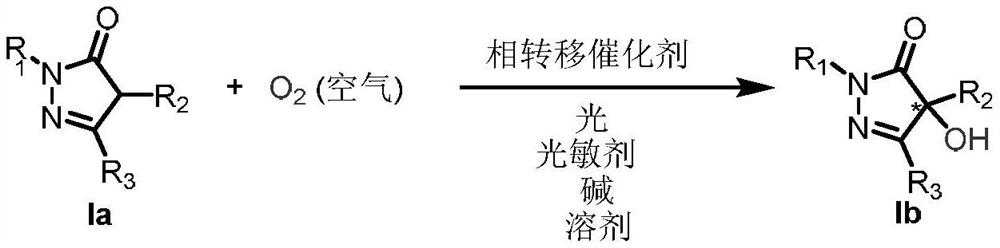

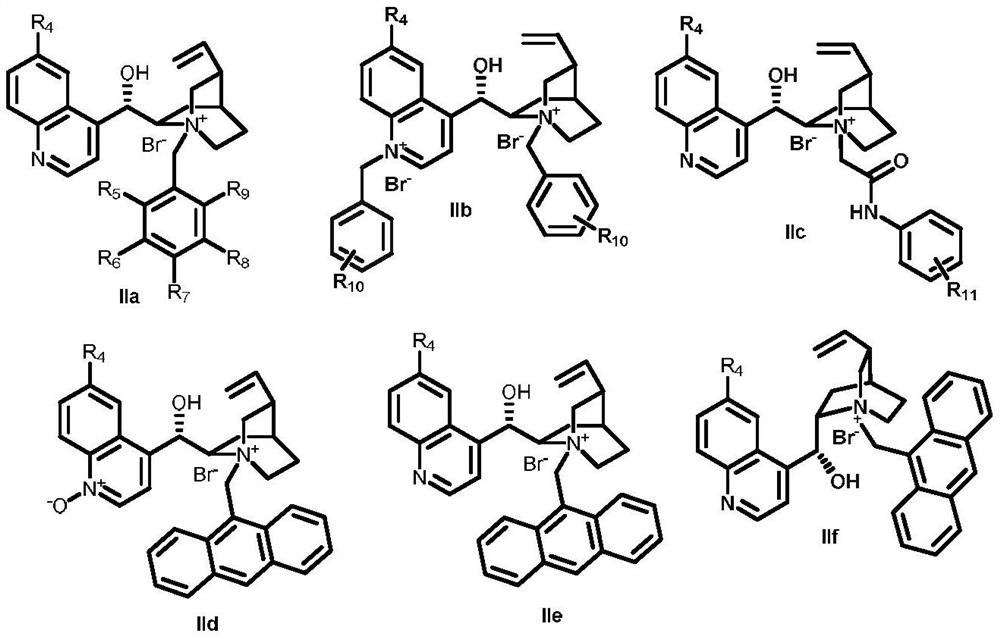

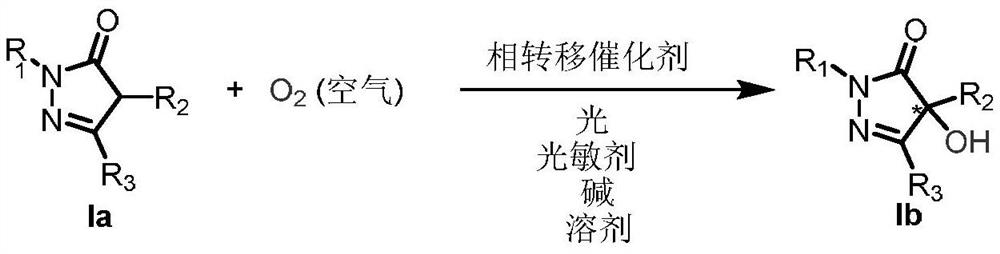

Method for realizing asymmetric alpha-hydroxylation of pyrazolone compounds through phase-transfer catalyzed photosensitized molecular oxygen

ActiveCN113956202AAchieve asymmetric α-hydroxylationEasy to separateOrganic chemistryPtru catalystPhotosensitizer

The invention discloses a method for realizing asymmetric alpha-hydroxylation of pyrazolone compounds by phase-transfer catalyzed photosensitized molecular oxygen, and belongs to the technical field of synthesis of chiral alpha-hydroxypyrazolone compounds in organic synthesis. According to the technical scheme, the preparation method is characterized by comprising the following steps: uniformly stirring and mixing the pyrazolone compounds, a phase transfer catalyst and a photosensitizer in a solvent, then adding alkali, and reacting at -78-60 DEG C under the condition of visible light and air or oxygen to prepare the chiral alpha-hydroxy pyrazolone compound. The method is mild in reaction condition, simple to operate, good in substrate applicability and environmental friendliness, low in cost and suitable for large-scale production.

Owner:XINXIANG MEDICAL UNIV

A kind of method for synthesizing oxaziridine by chemical enzymatic method

The invention discloses a method for synthesizing oxaziridine by chemical enzymatic method, belonging to the technical field of chemical synthesis, using aromatic aldehydes and aliphatic amines as reaction substrates, acetonitrile as a solvent, and ethyl D-mandelate as a peroxyacid precursor . The operation steps include adding enzyme, oxidant, reaction substrate, peroxyacid precursor, and solvent into a reaction vessel, and stirring and reacting at room temperature for 2 hours. It is proved by experiments that the lipase has a significant catalytic effect on the reaction, and can achieve a high cis-trans selectivity of more than 90%, and no by-products are generated during the reaction. Compared with traditional chemical synthesis methods, the method of the present invention has the advantages of metal-free catalysis, environmental protection, low cost, high efficiency, high selectivity, etc., and provides a new method for synthesizing oxaziridine compounds with cis-trans selectivity. train of thought.

Owner:JILIN UNIV

A surface treatment process for the inner cavity of a cylinder head

ActiveCN104174570BImprove corrosion resistanceImprove high temperature resistancePretreated surfacesCoatingsCylinder headLaser scanning

The invention discloses a treatment technology for an inner cavity surface of a cylinder cover. The treatment technology comprises processes as follows: cleaning the inner cavity surface of the cylinder cover to remove oil and dust; preheating the inner cavity surface of the cylinder cover to 70-90 DEG C in a far-infrared heating manner; performing spraying: spraying paint onto the inner cavity surface of the cylinder cover, wherein the thickness of the coating is in a range of 60-90 mu m; performing drying: continuously keeping the temperature of the inner cavity surface of the cylinder cover in a range of 70-90 DEG C and continuously drying the coating for 5-10 min in the far-infrared heating manner; performing sintering: performing high-temperature sintering on the coating of the inner cavity surface of the cylinder cover in a laser scanning heating manner at the temperature of 190-200 DEG C for 20-25 min to form a corrosion-resistant high-temperature-resistant ceramic film layer on an inner cavity of the cylinder cover. The treatment technology has the advantages that the coating is high-temperature-resistant and corrosion-resistant and has a catalytic combustion effect, so that the combustion efficiency of an engine is improved.

Owner:福建力宝动力机械有限公司

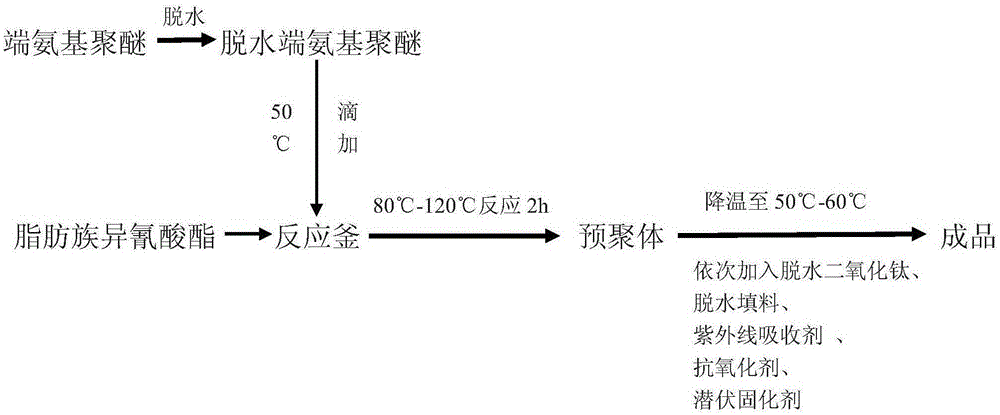

A kind of moisture curing one-component exposed polyurethane and its preparation method

ActiveCN103819647BHas a catalytic effectAvoid it happening againPolyurea/polyurethane coatingsAntioxidantUltraviolet lights

The invention relates to the technical field of polyurethane coatings, in particular to a moisture-curable one-component exposure-type polyurethane and a preparation method thereof. The moisture-curable one-component exposure-type polyurethane comprises fatty-group isocyanate, amine-terminated polyether, a latent curing agent, titanium dioxide, a filling material, an ultraviolet light absorber and an antioxidant. The preparation method comprises the following steps: dripping amine-terminated polyether subjected to vacuum dehydration into the fatty-group isocyanate, performing heat preservation when heating is carried out to obtain a prepolymer through polymerization, then sequentially adding dehydrated titanium dioxide, the filling material, the ultraviolet light absorber, the antioxidant and the latent curing agent into the prepolymer, uniformly stirring to form a finished product, and enabling the finished product to be in contact with and react with moisture in air to form a film. According to the method, the fatty-group isocyanate and the amine-terminated polyether are utilized, and the prepared polyurethane has the characteristics of compactness, high strength, high elasticity, wear resistance and corrosion resistance, is foamless, avoids yellowing, and can be applied to outdoor protective coatings. The fatty-group isocyanate and the latent curing agent have an excellent storage effect, and the storage period of the fatty-group isocyanate and the latent curing agent is longer than six months.

Owner:HEBEI YUYANGZELI WATERPROOF MATERIAL

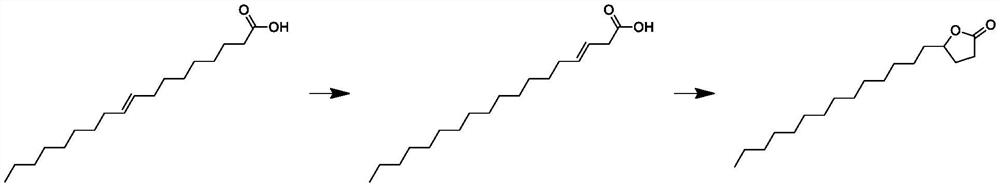

Synthesis method of biomass-based gamma-octadecalactone

ActiveCN113480498AUniform microporous structurePromote absorptionOrganic chemistryChemical recyclingPtru catalystDiethyl ether

The invention relates to a synthesis method of biomass-based gamma-octadecalactone, and belongs to the technical field of perfume synthesis. The synthesis method specifically comprises the following steps: 1, mixing a solvent and oleic acid, adding a catalyst and an additive at the temperature of 0-5 DEG C, and conducting heating and refluxing at the temperature of 70-85 DEG C for 8-10 hours; and 2, after the reaction is finished, conducting filtering, extracting the filtrate with deionized water and diethyl ether, concentrating the obtained organic phase under reduced pressure, and conducting drying to obtain gamma-octadecalactone. In the synthesis process, an additive is also prepared, the additive takes the diatomite as a raw material, after roasting, the microporous structure of the diatomite is more uniform, peculiar smell generated in the reaction process can be better absorbed, the product quality is improved, on the one hand, the alkali solution can react with metal oxides in the diatomite, the content of metal oxide is reduced, the content of silicon dioxide is increased, and the yield of the product is improved.

Owner:ANHUI HYEA AROMAS

A kind of preparation method of propylene glycol monoalkyl ether

ActiveCN109867589BHigh yieldHigh ratio of primary and secondary ethersEther preparation from oxiranesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPropanediol

The invention discloses a preparation method of propylene glycol monoalkyl ether. Propylene oxide and alcohol are used as raw materials to react under the catalysis of a modified magnetic solid base catalyst to prepare propylene glycol monoalkyl ether. The catalyst uses nickel ferrite as the magnetic core, magnesium aluminum oxide as the carrier, and cesium as the active component, and is obtained through transition metal modification. The method improves the reaction activity and selectivity, eases the operating conditions, and at the same time, the catalyst has a long service life, is easy to recycle and regenerate, has low production cost, overcomes various defects in the prior art, and can be used in industrialized production.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of composite cathode material for lithium-sulfur battery

ActiveCN113471421BImprove electrochemical performancePrevent oxidationPositive electrodesLi-accumulatorsTetrachlorideElectrical battery

The invention belongs to the technical field of lithium-sulfur battery preparation, and in particular relates to a preparation method of a lithium-sulfur battery composite cathode material. Will g‑C 3 N 4 and carbon nanotubes are dispersed in deionized water to obtain a mixed suspension; tin tetrachloride pentahydrate, ferric nitrate nonahydrate and cobalt nitrate hexahydrate are dissolved in deionized water to obtain a mixed solution; the mixed solution and the mixed suspension The solution was mixed and reacted to obtain a precipitate; the precipitate was dried and calcined to obtain a precursor A; the precursor A was etched with acid to obtain a precursor B; the precursor B was mixed with sulfur and ball milled to obtain a mixed powder; the mixed powder was calcined, A composite cathode material for a lithium-sulfur battery is obtained. Based on the defect of the electrochemical performance of the single doping material of lithium-sulfur battery, the present invention innovatively combines SnO 2 Templates and g‑C 3 N 4 The frame is also doped with lithium-sulfur battery raw materials, which greatly improves the battery performance.

Owner:SHANDONG UNIV OF TECH

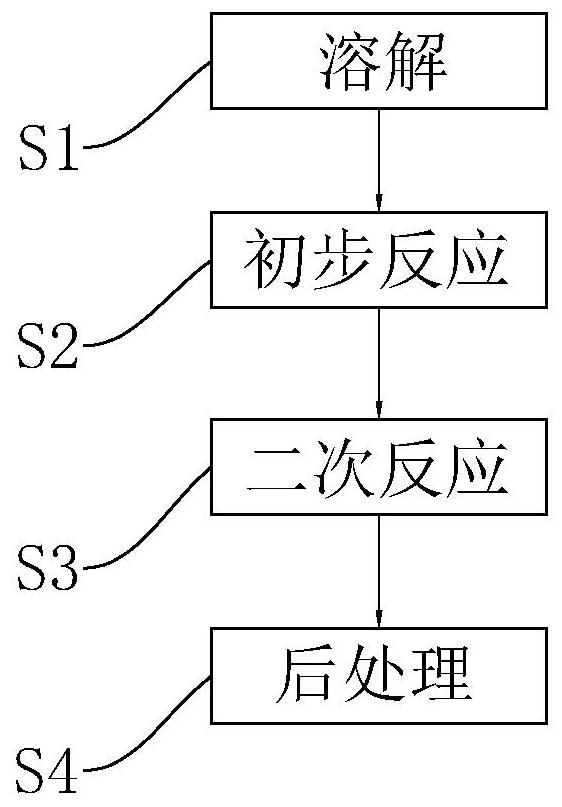

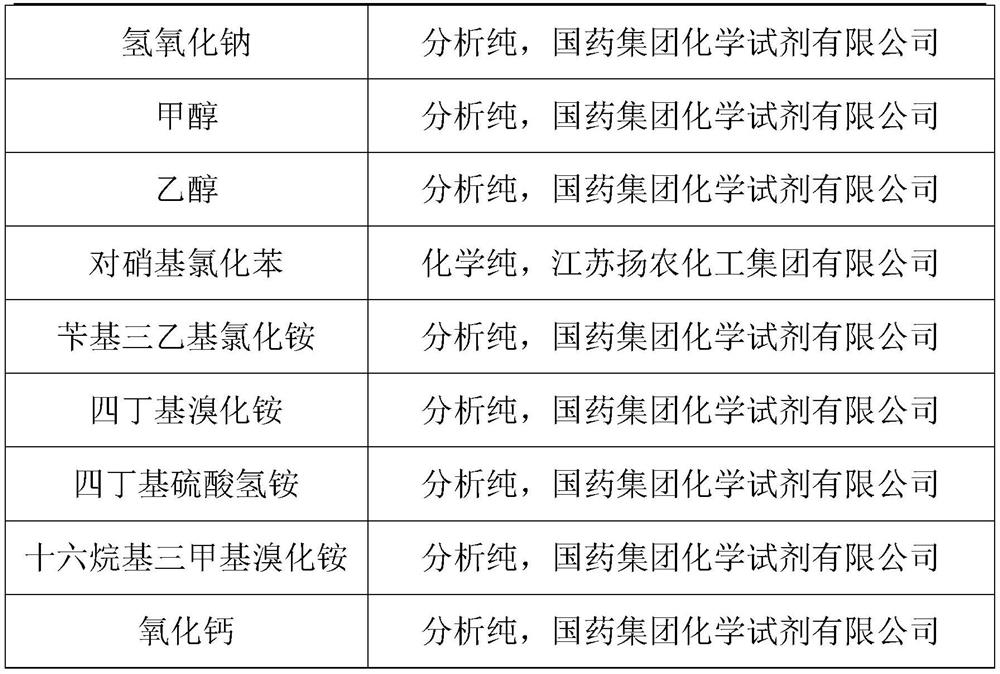

Synthetic method of p-nitroanisole

PendingCN112479891AHigh yieldHas a catalytic effectOrganic chemistryOrganic compound preparationPtru catalystP-nitroanisole

The invention relates to the technical field of organic intermediates, and particularly discloses a p-nitroanisole synthesis method. The method includes the steps: S1 dissolving p-nitroanisole, and dissolving sodium hydroxide and methanol in an organic solvent to form a first mixed solution, wherein the molar ratio of sodium hydroxide to methanol is (1.3-2): 8; S2, performing preliminary reaction,wherein p-nitrochlorobenzene is added into the first mixed solution for 2-3 h, and a second mixed solution is formed, and the molar ratio of the p-nitrochlorobenzene to the addition amount of the methanol in S1 is 1: 8; S3, carrying out secondary reaction: a catalyst is added into the second mixed solution, a quaternary ammonium salt catalyst is selected as the catalyst for 4-8 h, and the molar ratio of the addition amount of the catalyst to the addition amount of the methanol in S1 is (0.003-0.006): 8; S4, carrying out post-treatment, and carrying out post-treatment to obtain p-nitroanisole.By adding the quaternary ammonium salt catalyst, the final yield of p-nitroanisole can be improved.

Owner:ZHEJIANG HONGSHENG CHEM IND

A kind of ZIF-9 base porous carbon/carbon fiber composite material and preparation method thereof

ActiveCN109192985BHigh porosityLarge specific surface areaMaterial nanotechnologyElectrode carriers/collectorsPorous carbonLithium sulfur

A ZIF-9-based porou carbon / carbon fiber composite material and preparation method thereof belongs to the technical field of a preparation method of a metal nanoparticle doped porous carbon / carbon fiber conductive composite material, can solve the problems of poor conductivity and poor stability of the existing composite carbon material, wherein the carbon fiber of a carbon fiber fabric is taken asa growth substrate, and high-density arranged ZIF is grown on the growth substrate; 9, carbonize at high temperature in an inert gas atmosphere to generate porous carbon / carbon fib composite material, and that invention realizes a ZIF-9-based porous carbon and conductive substrate integrated conductive network structure, lithium sulfide batteries, sodium sulfide batteries, lithium-air batteries and fuel cells, electrocatalysis and other fields have a wide range of applications.

Owner:清创人和生态工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com