A kind of preparation method of propylene glycol monoalkyl ether

A technology of propylene glycol monoalkyl ether and propylene oxide, which is applied in the field of preparation of propylene glycol monoalkyl ether, can solve the problems of low product yield, poor catalyst stability, unsatisfactory isomer ratio, etc., and achieve high product yield, Less equipment corrosion, improved catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the magnetic solid base catalyst used in the present invention.

[0041] The modified magnetic solid base catalyst is prepared by impregnation and roasting, and the specific steps are as follows:

[0042] 1. Preparation of magnetic core: 0.1mol NiSO 4 .6H 2 O and 0.1mol Fe 2 (SO 4 ) 3 , prepare a salt solution with de-carbonated deionized water, add 1.5mol / L NaOH solution to the above solution under nitrogen protection, the end point pH=7, crystallize in a water bath at 40°C for 4 hours, and then wash with deionized water for 2 hours Once, washed twice with ethanol, dried at 100°C for 5h to obtain the magnetic core precursor, then in the muffle furnace, the temperature was raised to 900°C at 10°C / min and kept for 2h, cooled to room temperature to obtain NiFe 2 o 4 . Take 10g of glucose, dissolve it completely in 150mL of water, add NiFe 2 o 4 , mixed with ultrasound for 20min, put the obtained suspension into a 200mL autoclave, and car...

Embodiment 2

[0049] 15 mL of catalyst 1 obtained in Example 1 was loaded into a stainless steel fixed-bed reaction. The reactor was a stainless steel tube with an inner diameter of 8 mm and a length of 1 m, and stainless steel fillers were filled at both ends of the catalyst. Raw material propylene oxide and methanol are metered into the reactor through advection pump. At 100°C, the reaction pressure is 1.0MPa, the molar ratio of alkanol to alkanes is 4, and the liquid space velocity of the reaction bed is 2.0h -1 . The obtained product was analyzed and determined by GC, and the conversion rate of propylene oxide was 99.1%, the selectivity of propylene glycol methyl ether was 97.0%, and the ratio of primary and secondary ether isomers was 98:2.

Embodiment 3~6

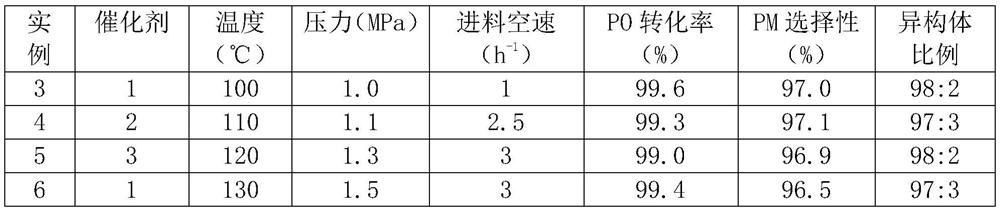

[0051] Compared with Example 2, the raw materials are still propylene oxide and methanol, and the catalyst and process conditions are changed. The experimental results are shown in the following table.

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com