Preparation method of rare earth sulfide pigment

A technology of rare earth sulfides and rare earth oxides, which is applied in the preparation/processing of rare earth metal compounds, rare earth metal sulfides, etc., can solve problems such as unfavorable expansion of production, and achieve low equipment requirements, lower reaction temperature, and shorter reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix 0.01mol of lanthanum carbonate, 0.035mol of zinc sulfide, 0.0006mol of sodium sulfate and 0.008mol of calcium chloride uniformly, H 2 / N 2 Reaction at 1100°C for 6 hours under the atmosphere to obtain yellow La 2 S 3 powder.

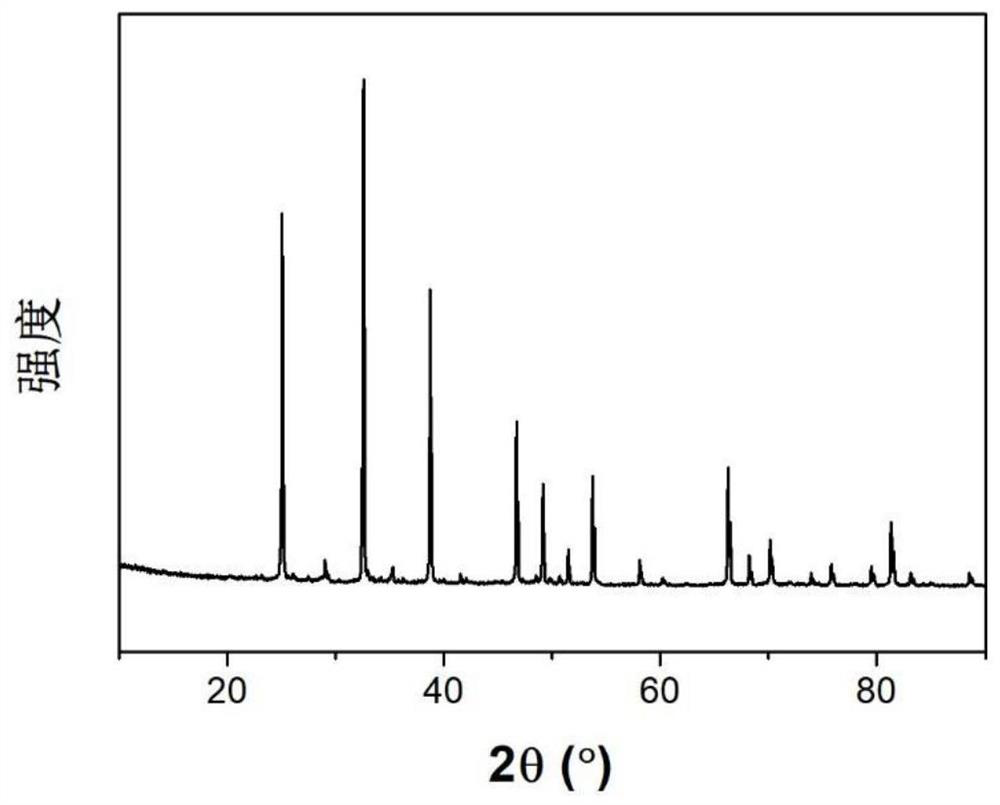

[0034] figure 1 La in Example 1 2 S 3 Product XRD diffraction pattern.

Embodiment 2

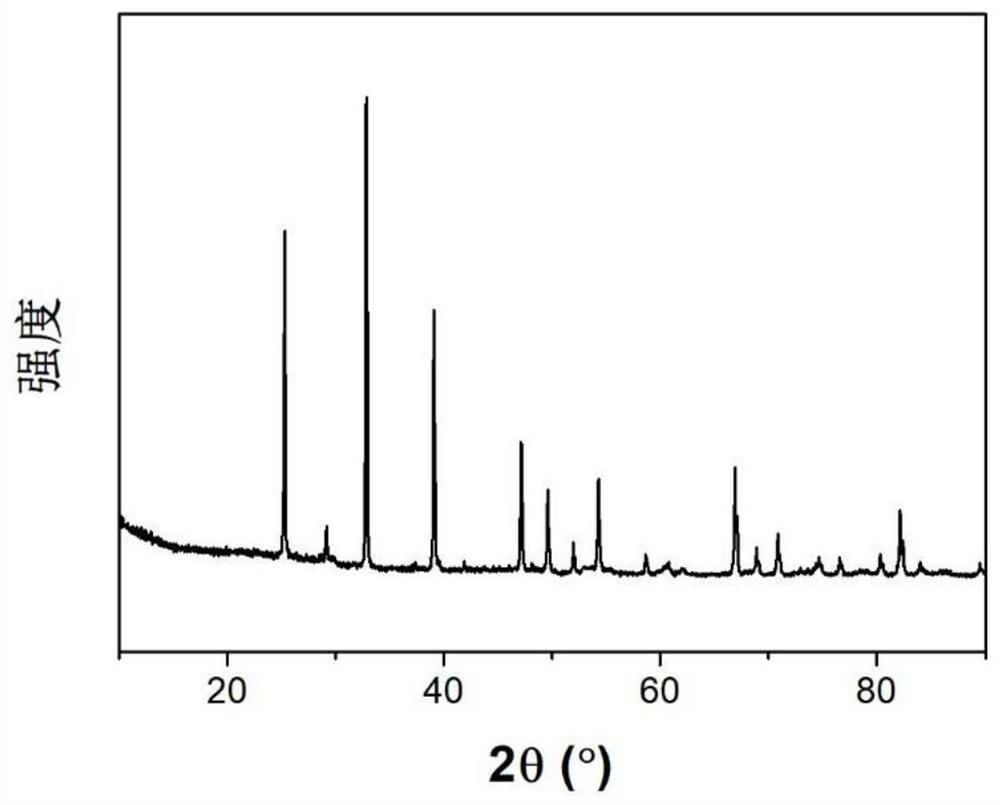

[0036] Mix 0.005mol lanthanum oxide, 0.02mol zinc sulfide, and 0.001mol sodium carbonate evenly, and 2 / N 2 Reaction at 1200°C for 6 hours under the atmosphere to obtain yellow La 2 S 3 powder.

Embodiment 3

[0038] Mix 0.005mol cerium oxalate, 0.02mol zinc sulfide and 0.001mol borax evenly, H 2 / Ar atmosphere at 1150°C for 8 hours to obtain red Ce 2 S 3 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com