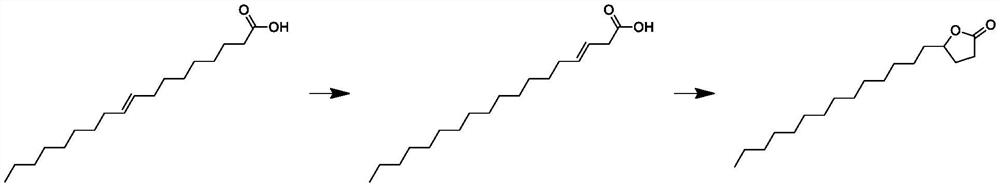

Synthesis method of biomass-based gamma-octadecalactone

A synthesis method and biomass technology, applied in organic chemistry and other directions, can solve problems such as affecting quality and complicated procedures, and achieve the effects of improving quality, uniform microporous structure, and reducing synthesis procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of additives:

[0024] Step S11, mixing diatomaceous earth and deionized water, stirring and mixing at 50°C for 30 minutes, passing through a 100-mesh sieve, drying at 40°C to constant weight, and then roasting at 700°C for 2 hours, Then cool to room temperature to obtain solid A; wherein, the mass ratio of diatomaceous earth and deionized water is 1:20;

[0025] Step S12, mix solid A and alkali solution, and react at a temperature of 50°C for 1 hour. After the reaction, wash the reacted solution with distilled water until the washing liquid is neutral. , dried to constant weight to obtain the additive. The alkali solution is an aqueous sodium hydroxide solution, and the mass fraction of the alkali solution is 15%; the dosage ratio of the solid A to the alkali solution is 1 g: 3 mL.

Embodiment 2

[0027] Preparation of additives:

[0028] Step S11, mixing diatomaceous earth and deionized water, then stirring and mixing at 75°C for 50 minutes, passing through a 100-mesh sieve, drying at 40°C to constant weight, and then roasting at 800°C for 2 hours, Then cool to room temperature to obtain solid A; wherein, the mass ratio of diatomaceous earth and deionized water is 1:20;

[0029] Step S12, mix the solid A and the alkali solution, and react at a temperature of 60°C for 1 hour. After the reaction, wash the reacted solution with distilled water until the washing liquid is neutral. , dried to constant weight to obtain the additive. The alkali solution is ammonia water, and the mass fraction of the alkali solution is 15%; the dosage ratio of the solid A and the alkali solution is 1g:3mL.

Embodiment 3

[0031] The synthetic method based on biomass-based gamma-octadecalactone comprises the following steps:

[0032] The first step is to mix the solvent and oleic acid, add the catalyst and additives at a temperature of 0°C, and heat to reflux at a temperature of 70°C for 8 hours;

[0033] In the second step, after the reaction is completed, filter, and extract the filtrate with deionized water and ether, concentrate and dry the obtained organic phase under reduced pressure to obtain γ-stearactone.

[0034] Wherein, the catalyst is concentrated sulfuric acid with a mass fraction of 98%; the solvent is n-hexane. The temperature during drying was 30°C. The additive is prepared in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com