Use of magnesium used refractory, preparation and use method of composite scale inhibitor

A technology of composite scale inhibitor and refractory material, applied in the field of flue gas desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

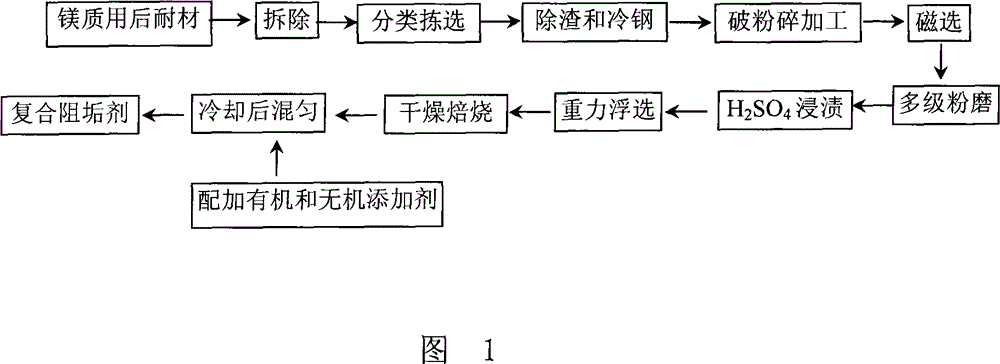

[0045] figure 1 It is the preparation process of composite antiscalant. In this example, the magnesia-carbon brick (chemical composition: MgO, 71.85%, F.C., 14.34%, CaO, 2.26%, Al 2 o 3 , 4.43%, SiO 2 , 3.10%, FeO, 0.36%) After sorting and sorting, removing surface slag and cold steel, crushing and crushing, magnetic separation and iron removal, and multi-stage grinding, it is made into 100-mesh powder. 2 SO 4 Immerse in the solution for 1 hour, remove impurities such as dust and inclusions by gravity flotation, then dry at 60°C for 2 hours, and roast at 600°C for 2 hours, after cooling, add 1wt% acetonitrile to the magnesium refractory powder The diacid, 10wt% sodium humate and 1wt% sodium sulfate are mixed evenly to form a 5.0wt% solution, and added to the desulfurization tower in an appropriate amount.

[0046] The original flue gas is the exhaust gas from a sintering plant of a steel company, with a flow rate of 90,000m 3 / h, the temperature is 120°C, SO in flue ga...

Embodiment 2

[0049] Such as figure 1 As shown, after the cement industry uses magnesia-calcium bricks (chemical composition is: MgO, 75.57%, CaO, 19.85%, Al 2 o 3 , 0.51%, SiO 2 , 1.15%, Fe 2 o 3 , 0.74%) after sorting and sorting, removing surface slag and cold steel, crushing and crushing, magnetic separation and iron removal, and multi-stage grinding, it is made into a 325-mesh powder. 2 SO 4 Immerse in the solution for 8 hours, remove impurities such as dust and inclusions by gravity flotation, then dry at 200°C for 8 hours, and roast at 1000°C for 8 hours. The diacid, 10wt% sodium humate and 10wt% sodium sulfate are mixed evenly to form a 30.0wt% solution, which is added to the desulfurization tower in an appropriate amount.

[0050] The original flue gas is the exhaust flue gas from a power plant with a flow rate of 720,000m 3 / h, the temperature is 130℃, SO in the flue gas 2 The concentration is 2500~3800mg / Nm 3 . The desulfurizer is limestone slurry, the fineness of lime...

Embodiment 3

[0053] Such as figure 1 As shown, the magnesia-alumina bricks used in the iron and steel industry (chemical composition: MgO, 50.25%, CaO, 1.28%, Al 2 o 3 , 23.51%, SiO 2 , 2.50%, Fe 2 o 3 , 0.44%) after sorting and sorting, removing surface slag and cold steel, crushing, magnetic separation and iron removal, and multi-stage grinding, it is made into 100-mesh powder. 2 SO 4 Immerse in the solution for 4 hours, remove impurities such as dust and inclusions by gravity flotation, then dry at 200°C for 2 hours, and roast at 900°C for 6 hours. After cooling, add 30wt% hexene di After the acid and 10wt% sodium humate are mixed evenly, they are mixed with the limestone solid powder desulfurizer at a ratio of 0.05wt%, and then made into a 20.0wt% solution, and added in an appropriate amount to the desulfurization tower.

[0054] The original flue gas is the exhaust gas from a sintering plant of a steel company, with a flow rate of 60,000m 3 / h, the temperature is 130℃, SO in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com