Ternary metal oxide thin film catalyst and preparation method thereof

A technology of oxide film and ternary metal, applied in the fields of energy and environment, can solve the problems of complex steps, inflexibility, no bidirectional catalysis, etc., and achieve the effect of large specific surface area, wide application range and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

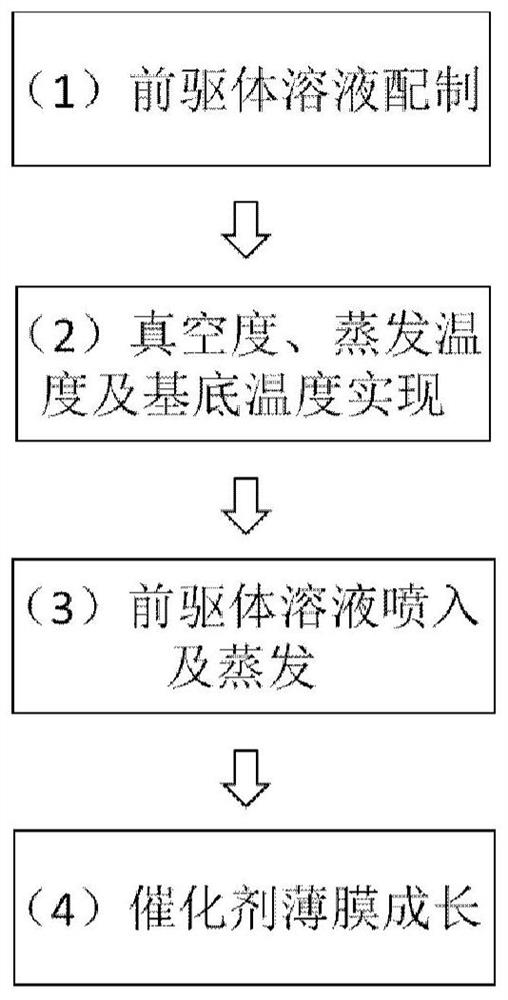

[0026] The present invention also provides a method for preparing the aforementioned ternary metal oxide thin film catalyst, comprising the following steps: (1) configuring metal-organic compound solutions of three metals, mixing them as precursor solutions, and the three metals are independently ground is selected from noble metals, transition metals or rare earth metals; (2) A uniform thin layer of ternary metal oxides is formed on the substrate by pulse atomization thermal evaporation chemical vapor deposition.

[0027] Wherein in step (1), the ratio of the obtained ternary metal oxide is adjusted through the concentration ratio of metal organic compounds of three different metals; the concentration of the three metal organic compounds is in the order of mmol / L.

[0028] Wherein step (2) specifically comprises the following steps:

[0029] Sub-step (21) adjust the evaporation temperature, substrate temperature and vacuum degree in the pulse atomization thermal evaporation c...

Embodiment 1

[0035] Preparation of Zn-Zr-Cu oxide thin film catalysts, such as figure 1 shown, including the following steps:

[0036] (1) The organometallic compound solutions of Zn, Zr and Cu are configured respectively, and mixed as a precursor solution, wherein the concentrations of Zn, Zr and Cu three metals in the precursor solution are 5mmol / L;

[0037] (2) Adjust the evaporation temperature in the pulsed spray evaporation–chemical vapor deposition (PSE-CVD) device to 200°C and the substrate temperature to 350°C, Introduce nitrogen and oxygen to maintain the pressure inside the device at 2kPa;

[0038] (3) Spray into the precursor solution at a frequency of 4 Hz and a pulse width of 2.5 ms for evaporation to obtain precursor vapor;

[0039] (4) Use the nitrogen and oxygen that step (2) feeds to transport the precursor vapor to the surface of 1g metal mesh for chemical reaction, and grow a 150nm thick Zn-Zr-Cu oxide thin layer on it, with a thin layer weight of 14mg.

[0040] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com