A kind of ZIF-9 base porous carbon/carbon fiber composite material and preparation method thereof

A ZIF-9, composite material technology, applied in nanotechnology for materials and surface science, fuel cells, electrode carriers/current collectors, etc., can solve problems such as poor conductivity and poor stability, and achieve high conductivity and high Porosity, solve the effect of low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Implement a kind of preparation method of ZIF-9 base porous carbon / carbon fiber composite material, this preparation method is carried out in order according to the following steps:

[0032] (1) Fiber surface pretreatment of carbon fiber fabrics:

[0033] The carbon fiber fabric was ultrasonically cleaned in isopropanol for 30 min, then dried in an air atmosphere at 80 °C, and heat-treated at 600 °C in an Ar atmosphere for 6 h; then, it was treated with concentrated nitric acid at 150 °C for 12 h in a Rinse with deionized water until neutral, and dry; finally, soak in ethylenediamine at 50°C for 24 h, and dry for later use;

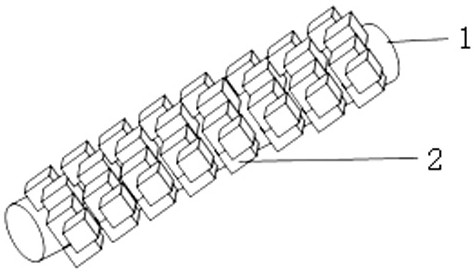

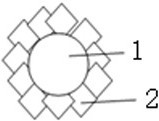

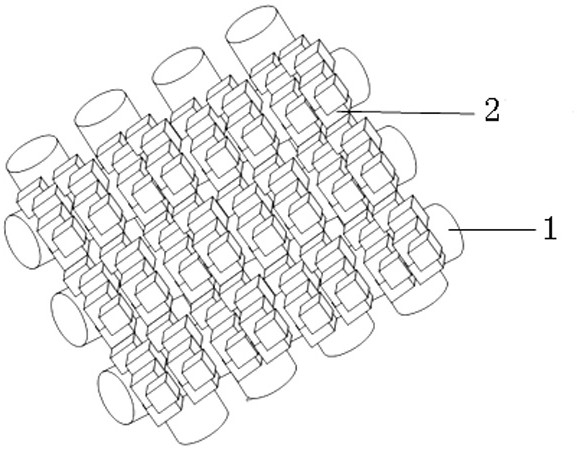

[0034] (2) Preparation of ZIF-9 / carbon fiber three-dimensional composite material:

[0035]Weigh 0.6 g Co(NO 3 ) 2 •6H 2 O (dissolved in 40 mL N,N-dimethylformamide (DMF) (solution Ⅰ), weighed 0.52 g benzimidazole (BIM) and dissolved in 20 mL N,N-dimethylformamide (DMF) In (solution II), solution I was poured into the autoclave, soaked the car...

Embodiment 2

[0039] Implement a kind of preparation method of ZIF-9 base porous carbon / carbon fiber composite material, this preparation method is carried out in order according to the following steps:

[0040] (1) Fiber surface pretreatment of carbon paper:

[0041] Carbon paper with a carbon fiber diameter of 10 μm was ultrasonically cleaned in isopropanol for 60 min, then dried in an air atmosphere at 80 °C, N 2 Heat treatment at 600°C for 10 h in atmospheric atmosphere; then, treat with concentrated nitric acid at 150°C in an autoclave for 24 h, rinse with deionized water until neutral, and dry; finally, soak in hydrazine at 50°C for 24 h , dried for later use;

[0042] (2) Preparation of ZIF-9 / carbon fiber three-dimensional composite material:

[0043] Weigh 1.2 g CoCO 3 •6H 2 O was dissolved in 40 mL of nitrogen-methylpyrrolidone (solution Ⅰ), 1.04 g of benzimidazole (BIM) was weighed and dissolved in 20 mL of nitrogen-methylpyrrolidone (solution Ⅱ), solution Ⅰ was poured into th...

Embodiment 3

[0049] Implement a kind of preparation method of ZIF-9 base porous carbon / carbon fiber composite carbon material, this preparation method is carried out in sequence according to the following steps:

[0050] (1) Fiber surface pretreatment of carbon felt:

[0051] Carbon felt with a carbon fiber diameter of 1 μm was ultrasonically cleaned in isopropanol for 5 min, then dried in an air atmosphere at 80°C, N 2 Heat treatment at 600°C for 6 h in atmospheric atmosphere; then, treat with concentrated nitric acid at 150°C in an autoclave for 12 h, rinse with deionized water until neutral, and dry; finally, soak in triethanolamine at 50°C for 24 h , dried for later use;

[0052] (2) Preparation of ZIF-9 / carbon fiber three-dimensional composite material:

[0053] Weigh 0.9 g CoSO 4 •7H 2 O was dissolved in 40 mL of ethanol (solution Ⅰ), and 0.78 g of benzimidazole (BIM) was weighed and dissolved in 20 mL of ethanol (solution Ⅱ). The carbon felt was soaked in it and kept for 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com