A kind of moisture curing one-component exposed polyurethane and its preparation method

A one-component, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low reactivity, coating bubbling, poor mechanical properties of cured products, etc., to achieve good storage stability, good stability The effect of stability and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

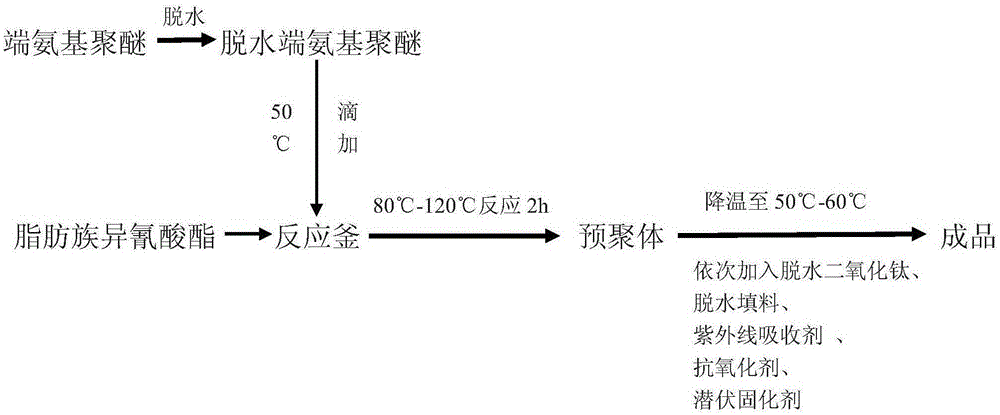

Method used

Image

Examples

Embodiment 1

[0045] Add 10% isophorone diisocyanate into the reaction kettle, heat up to 50-60°C, then drop 50% amino-terminated polyether D2000 to remove moisture, raise the temperature after the dropwise addition, and keep warm at 80°C-120°C for reaction After 2 hours, the prepolymer was prepared, and then the temperature was lowered to 50-60°C, and 5% dehydrated rutile titanium dioxide, 30% filler kaolin, 0.5% ultraviolet absorber UV531, 0.5% antioxidant 1010 and 4% latent curing agent amino Formate diazolidine HardenerVPLS2959, after stirring for 0.5h, the material is discharged to form a finished product, and then reacts to form a film by contacting with moisture in the air.

Embodiment 2

[0047] Add 15% hexamethylene diisocyanate into the reaction kettle, heat up to 50-60°C, then add 35% amino-terminated polyether D2000 to remove moisture dropwise, raise the temperature after the dropwise addition, and keep warm at 80°C-120°C for reaction Prepare the prepolymer after 2 hours, then lower the temperature to 50-60°C, add 5% dehydrated rutile titanium dioxide, 40% filler talcum powder, 0.5% ultraviolet absorber UV327, 0.5% antioxidant 168 and 4% latent curing agent Carbamate diazolidine HardenerVPLS2959, after stirring for 0.5h, it is discharged to form a finished product, and then reacts to form a film by contacting with moisture in the air.

Embodiment 3

[0049] Add 20% xylylene isocyanate or 20% 4,4 dicyclohexylmethane diisocyanate into the reaction kettle, heat up to 50-60°C, then add 40% amino-terminated polyether D2000 to remove moisture, drop After the addition, heat up, keep warm at 80°C-120°C for 2 hours to prepare the prepolymer, then cool down to 50-60°C, add 10% dehydrated rutile titanium dioxide, 20% filler talc powder, 0.2% ultraviolet absorber UV531 , 0.2% antioxidant 168 and 9.6% latent curing agent urethane diazolidine HardenerVPLS2959, after stirring for 0.5h, the material is discharged to form a finished product, and then reacts to form a film by contacting with moisture in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com