Preparation method of composite cathode material for lithium-sulfur battery

A technology for composite positive electrode materials and lithium-sulfur batteries, which is applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of reduced electrical conductivity of materials, and achieve the effects of preventing oxidation, good electrochemical performance, and protecting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

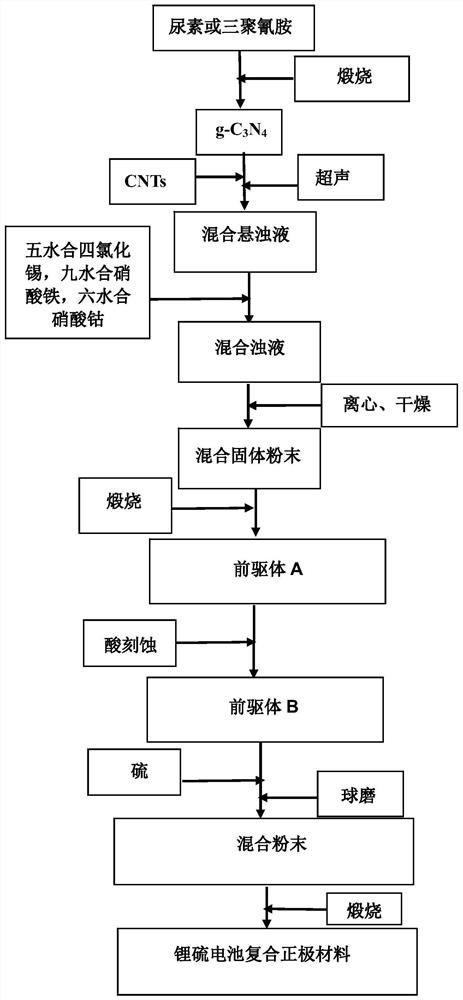

Method used

Image

Examples

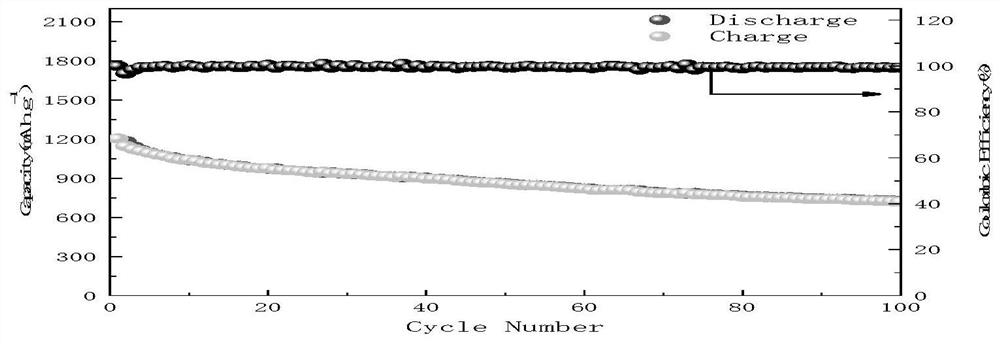

Embodiment 1

[0055] (1) Synthesis of g-C 3 N 4

[0056] Put 5g of urea in a porcelain boat, put the porcelain boat into a tube furnace for calcination, in a nitrogen atmosphere, raise the temperature to 550°C at a rate of 5°C / min, and keep it at this temperature for 3h to obtain g-C 3 N 4 ;

[0057] (2) Synthetic precursor

[0058] 0.15g g-C 3 N 4 After mixing with 0.08g CNTs, add it into 15mL deionized water, and ultrasonically disperse for 30min to obtain a mixed suspension; In ionized water, the mixed solution was obtained; the mixed solution and the mixed suspension were stirred and reacted at 20°C for 12 hours to obtain a precipitate; the precipitate was centrifuged and dried to obtain a powder, and the powder obtained after the centrifuged drying was placed in a porcelain boat, and the porcelain boat was placed Put it into a tube furnace for calcination, in a nitrogen atmosphere, raise the temperature to 500°C at a heating rate of 2°C / min, and keep it at this temperature for 3...

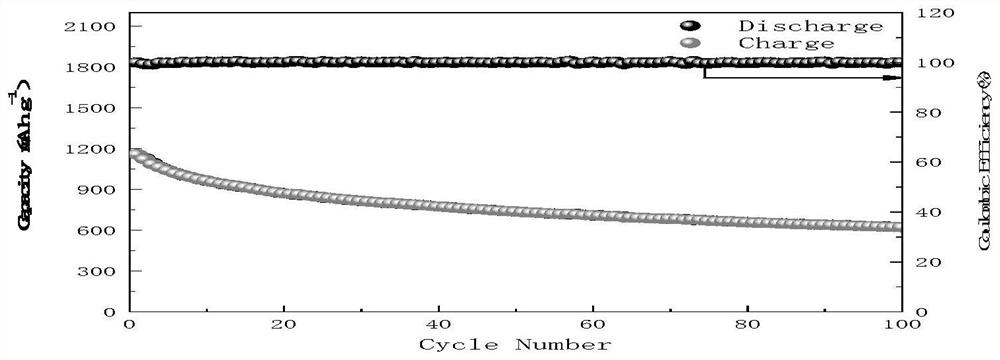

Embodiment 2

[0064] (1) Synthesis of g-C 3 N 4

[0065] Put 5g of urea in a porcelain boat, put the porcelain boat into a tube furnace for calcination, in a nitrogen atmosphere, raise the temperature to 550°C at a rate of 5°C / min, and keep it at this temperature for 3h to obtain g-C 3 N 4 ;

[0066] (2) Synthetic precursor

[0067] 0.15g g-C 3 N 4 After mixing with 0.08g CNTs, add it into 15mL deionized water, and ultrasonically disperse for 30min to obtain a mixed suspension; In ionized water, the mixed solution was obtained; the mixed solution and the mixed suspension were stirred and reacted at 20°C for 12 hours to obtain a precipitate; the precipitate was centrifuged and dried to obtain a powder, and the powder obtained after the centrifuged drying was placed in a porcelain boat, and the porcelain boat was placed Put it into a tube furnace for calcination, in a nitrogen atmosphere, raise the temperature to 500°C at a heating rate of 2°C / min, and keep it at this temperature for 3...

Embodiment 3

[0073] The urea in step (1) in Example 1 was changed to melamine, the calcination temperature was changed to 600° C., the holding time was changed to 2.5 h, and the rest of the steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com