Preparation method of perovskite catalyst and product and application thereof

A catalyst and perovskite technology, applied in the fields of catalysis and material chemistry, can solve the problems of complicated preparation process and lengthy steps, and achieve the effects of high atom utilization, easy acquisition, and simple and efficient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

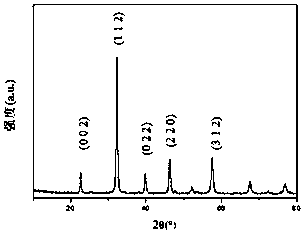

[0030] Weigh the molar ratio as Fe(NO 3 ) 3 9H 2 O:La(NO 3 ) 3 ·6H 2 O:C 4 h 4 CoO 4 4H 2 O:PdCl 2 Citric acid monohydrate = 0.1 : 1 : 0.9 : 1 / 50 : 3, where La(NO 3 ) 3 is 0.01 mol. respectively dissolved in 20ml deionized water, in which PdCl 2 Add 0.2ml of hydrochloric acid dropwise and dissolve in 20ml of deionized water at 50°C. First, fully mix the cobalt metal precursor solution, the iron metal precursor solution and the palladium metal precursor solution, then add the lanthanum metal precursor solution and mix well, and finally add the citric acid solution and mix well. Then put the mixture solution into an oven for drying, the temperature of the oven is 100° C., and bake for 3 hours. Then the mixture was kept warm in a muffle furnace, the heat preservation atmosphere was air, and the heating rate was 5° C. / min. After heat preservation, naturally cool to room temperature to obtain perovskite LaFe 0.1 co 0.9 o 3 material, its XRD pattern is shown in fi...

Embodiment 2

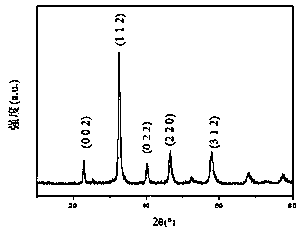

[0033] Weigh the molar ratio as Fe(NO 3 ) 3 9H 2 O:La(NO 3 ) 3 ·6H 2 O:C 4 h 4 CoO 4 4H 2 O:PdCl 2 Citric acid monohydrate = 0.4 : 1 : 0.6 : 1 / 50 : 3, where La(NO 3 ) 3 is 0.01 mol. respectively dissolved in 20ml deionized water, in which PdCl 2 Add 0.2ml of hydrochloric acid dropwise and dissolve in 20ml of deionized water at 50°C. First, fully mix the cobalt metal precursor solution, the iron metal precursor solution and the palladium metal precursor solution, then add the lanthanum metal precursor solution and mix well, and finally add the citric acid solution and mix well. Then put the mixture solution into an oven for drying, the temperature of the oven is 100° C., and bake for 3 hours. Then the mixture was kept warm in a muffle furnace, the heat preservation atmosphere was air, and the heating rate was 5° C. / min. After heat preservation, naturally cool to room temperature to obtain perovskite LaFe 0.4 co 0.6 o 3 Material, LaFe 0.4 co 0.6 o 3 XRD diag...

Embodiment 3

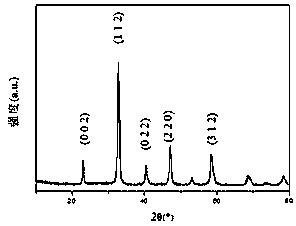

[0036] Weigh the molar ratio as Fe(NO 3 ) 3 9H 2 O:La(NO 3 ) 3 ·6H 2 O:C 4 h 4 CoO 4 4H 2 O:PdCl 2 Citric acid monohydrate = 0.9 : 1 : 0.1 : 1 / 50 : 3, where La(NO 3 ) 3 is 0.01 mol. respectively dissolved in 20ml deionized water, in which PdCl 2 Add 0.2ml of hydrochloric acid dropwise and dissolve in 20ml of deionized water at 50°C. First, fully mix the cobalt metal precursor solution, the iron metal precursor solution and the palladium metal precursor solution, then add the lanthanum metal precursor solution and mix well, and finally add the citric acid solution and mix well. Then put the mixture solution into an oven for drying, the temperature of the oven is 100° C., and bake for 3 hours. Then the mixture was kept warm in a muffle furnace, the heat preservation atmosphere was air, and the heating rate was 5° C. / min. After heat preservation, naturally cool to room temperature to obtain perovskite LaFe 0.9 co 0.1 o 3 Material. The material is prepared as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com