Microfocus field emission electron source based on carbon nanotubes and preparation method thereof

A technology of carbon nanotubes and carbon nanotube cathodes, which is applied in the field of field emission electron sources, can solve the problem that the focus size of micro-focus X-ray sources is not small enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] Preparation Examples:

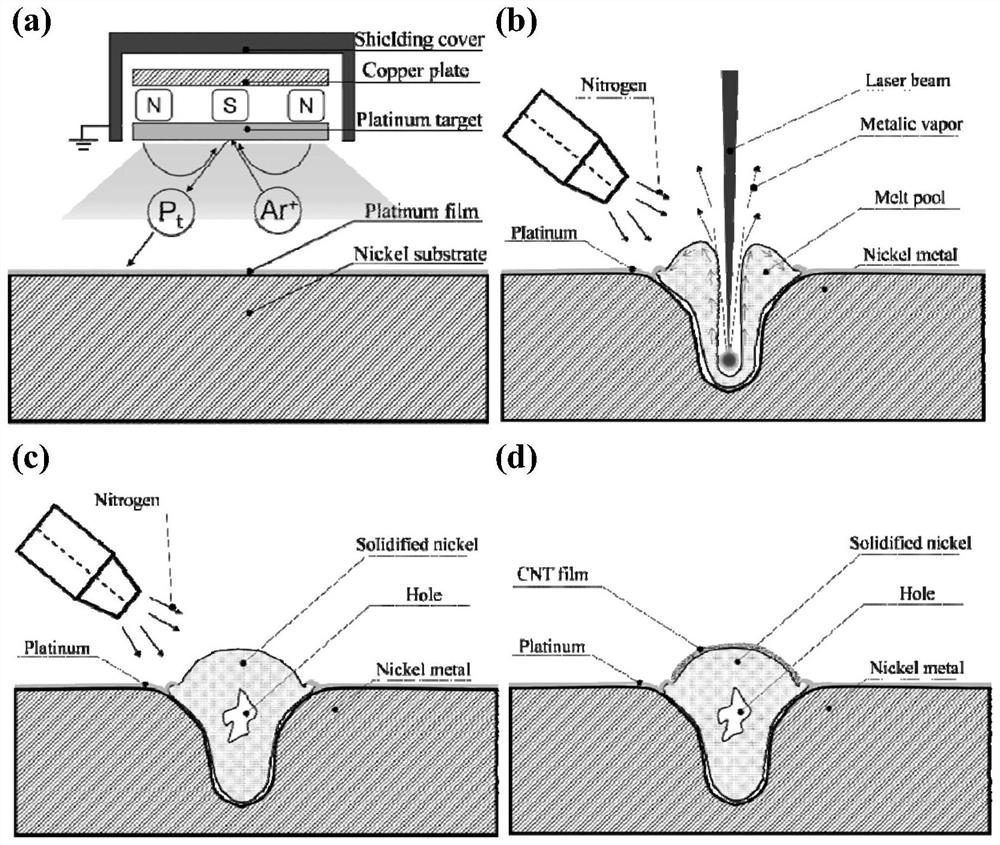

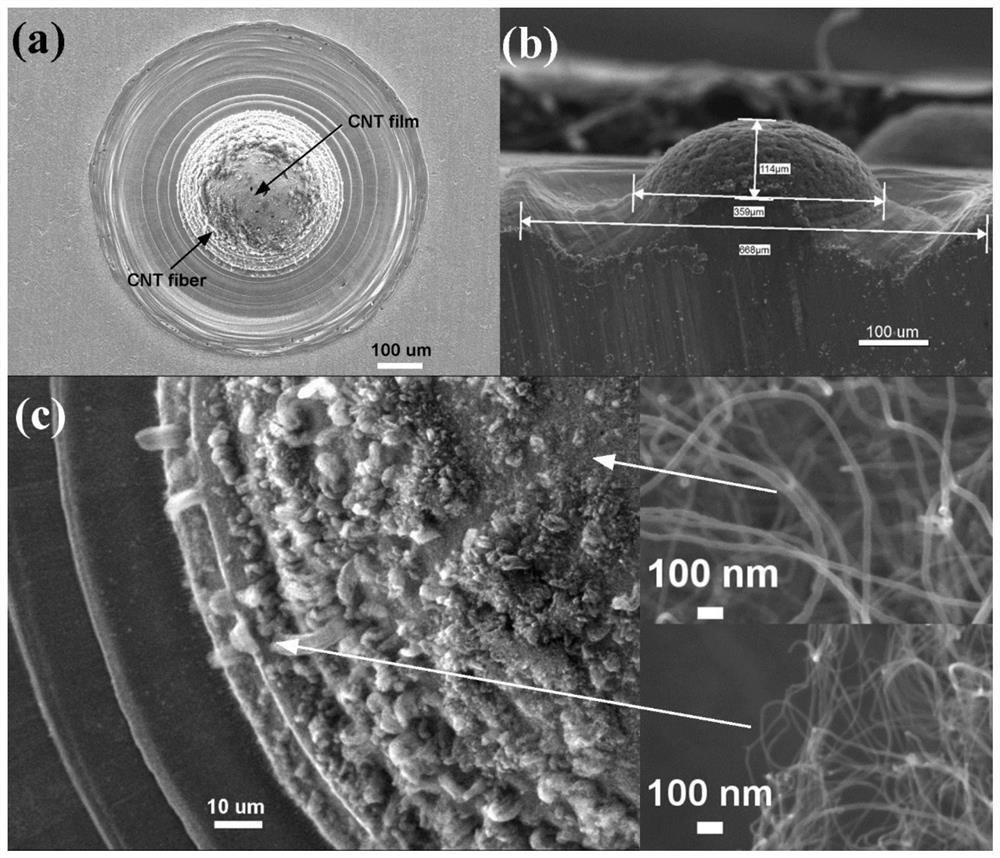

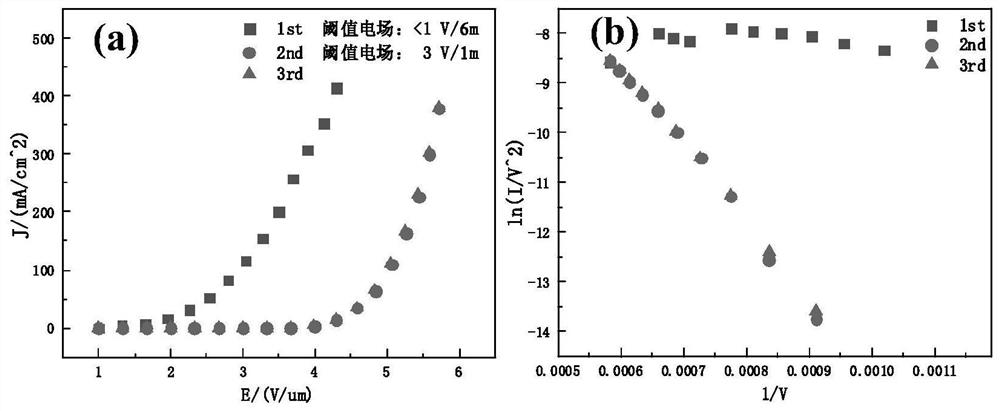

[0032] In the preparation of the carbon nanotube cathode, a layer of metal platinum (vacuum degree: 9Pa, sputtering current: 30mA, sputtering time: 600s) was first plated on the surface of the nickel substrate by magnetron sputtering, such as figure 1 (a). Then the nickel substrate is spot ablated with negative defocus by pulsed laser (wavelength: 1064nm, frequency: 3Hz, output current: 50-150A, negative defocus distance: 0.00-0.50mm). Negative defocusing ablation of pulsed laser can make the internal particles of nickel metal melt and erupt to the surface to form a spherical shell, such as figure 1 b and 1c are shown. During negative defocus ablation, the laser focus is inside the material, which melts the nickel metal inside, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com