Preparation method of composite anode during electrolytic extraction of titanium metal

A composite anode and electrolytic extraction technology, applied in the direction of electrodes, electrolytic process, electrolytic components, etc., can solve the problems of large amount of reducing agent and high energy consumption, and achieve the effects of reducing production costs, accelerating anode reaction, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the composite anode during the electrolytic extraction of metal titanium of the present invention comprises the following steps:

[0020] a. Raw material preparation: measure the titanium content M in the titanium liquid obtained in the process of producing titanium dioxide by the sulfuric acid method;

[0021] b. Mixing of composite anode materials: add 12%M to 20%M reducing agent to the titanium solution obtained in step a, then add 1%M to 5%M binder, and mix evenly to obtain a mixed material; wherein, Reducing agent + binder = 13%M ~ 23%M;

[0022] c. Preparation of composite anode: Press the mixed material obtained in step b under a pressure of 0.5-1.5MPa, dry at 100-120°C for 3-5 hours, and calcinate at 300-350°C for 2 ~4h, is that the crystal water is removed from the material at high temperature to obtain a titanium-containing composite anode;

[0023] d. Production of titanium metal: the titanium-containing composite anode obtained in...

Embodiment 1

[0037] Step 1, anode preparation

[0038] Raw materials: titanium liquid, carbon powder, asphalt;

[0039] According to a certain volume of titanium liquid, according to the determined hydrolysis rate, calculate the Ti content after hydrolysis, add 17% carbon powder and 3% pitch according to the mass ratio, and mix evenly. Rinse according to the existing steps of sulfuric acid titanium dioxide to obtain a titanium-containing mixture. According to 10kg / cm 2 It is formed under high pressure, and then dried at 100-120°C for 3-5 hours. After the free water is released from the formed material block, it is calcined at 300-350°C for 2-4 hours. Composite anode, the obtained sample block falls freely at a height of 1 meter, and the sample block remains intact, which can meet the requirements of the next step of electrolysis. Analysis of this material by means of X-ray diffraction shows that it is still C and TiO 2 mixture.

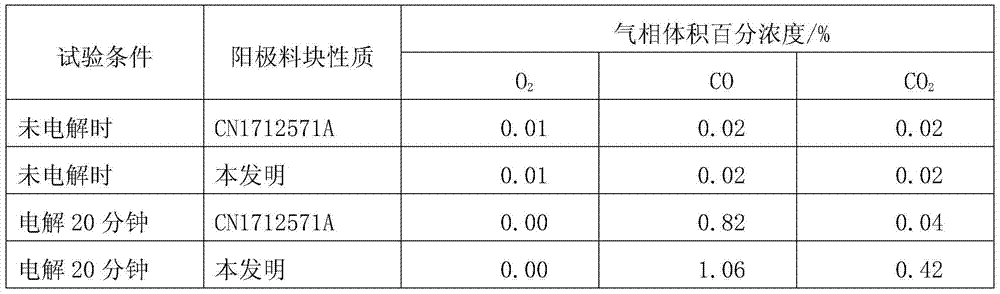

[0040] Step 2, molten salt electrolysis

[0041] The blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com