Method for reinforcing lime stone slurry activity in smoke desulfurizing process and combined additive

A technology for limestone slurry and desulfurization process, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation to achieve the effects of reducing the amount of residue, improving operating flexibility, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In this method of strengthening the activity of limestone slurry in the flue gas desulfurization process, the following two substances are directly added to the limestone slurry at normal temperature and pressure:

[0031] (1) The addition amount of industrial adipic acid can be selected as: 850mg / l, 900mg / l, 1000mg / l, 1050mg / l, 1100mg / l or 1150mg / l.

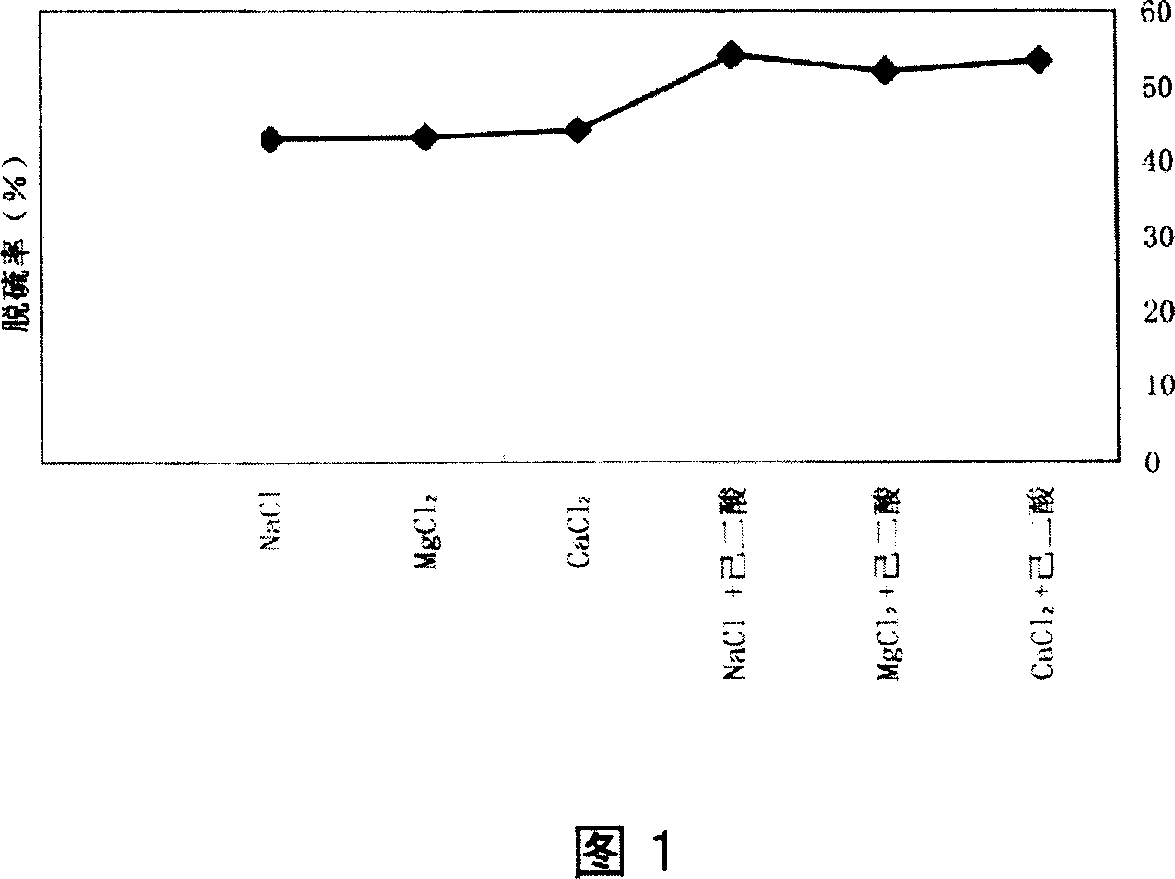

[0032] (2) The amount of industrial sodium chloride can be selected as: 850mg / l, 900mg / l, 950mg / l, 1000mg / l, 1100mg / l or 1200mg / l, 1300mg / l, 1400mg / l, 1500mg / l , 1600mg / l, 1700mg / l, 1800mg / l, 1900mg / l, 2000mg / l, 2100mg / l, 2200mg / l, 2500mg / l, 2700mg / l, 3000mg / l, 3200mg / l, 3400mg / l or 3450mg / l. The above sodium chloride NaCl can use magnesium chloride MgCl 2 or Calcium Chloride CaCl 2 substitute.

[0033] This combined additive for enhancing the activity of limestone slurry in the flue gas desulfurization process, its components and mass ratio can be selected:

[0034] Adipic acid: chloride salt-1:1; adipic acid: chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com