Method for producing molecular sieve by fly ash and molecular sieve prepared thereby

A molecular sieve and fly ash technology, applied in the field of molecular sieve, can solve the problem of high cost and achieve the effects of sufficient raw materials, reduced manufacturing cost and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

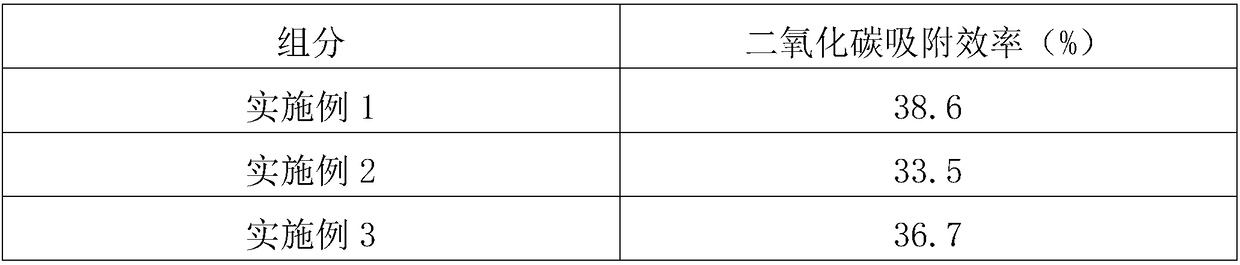

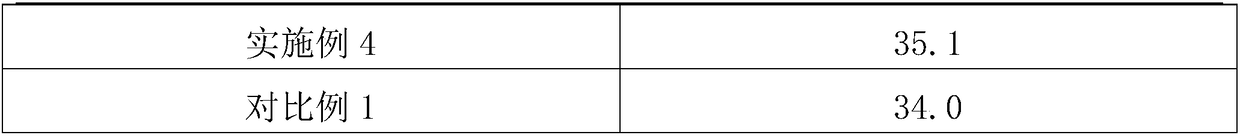

Examples

Embodiment 1

[0033] In this embodiment, the molecular sieve manufactured by fly ash is prepared through the following steps:

[0034](1) Mixing: The fly ash is subjected to magnetic separation-roasting-cooling pretreatment, wherein the magnetic separation adopts a high-efficiency magnetic separator for magnetic separation 5 times, and then it is roasted in a muffle furnace with a roasting temperature of 650 ° C for 3 hours, and cooled to At room temperature, put the pretreated fly ash, nano-anion powder, plant ash and caustic soda into a pulverizer to pulverize to obtain a mixed powder. The particle size of the mixed powder is 45 μm. Add it into a mixer, and stir at a speed of 35 rpm for 30 minutes to obtain a uniform mixed solution with good fluidity;

[0035] (2) Crystallization: the mixed solution obtained in step (1) was put into an autoclave and heated for 25 hours, and the heating temperature was 95°C. The mixed solution in the autoclave crystallized and separated out fly ash molecul...

Embodiment 2

[0040] In this embodiment, the molecular sieve manufactured by fly ash is prepared through the following steps:

[0041] (1) Mixing: the fly ash is subjected to magnetic separation-roasting-cooling pretreatment, wherein the magnetic separation adopts a high-efficiency magnetic separator magnetic separation for 3 times, and then it is roasted in a muffle furnace with a roasting temperature of 550 ° C for 2 hours, and cooled to At room temperature, put the pretreated fly ash, nano-anion powder, plant ash and caustic soda into a pulverizer to pulverize to obtain a mixed powder. The particle size of the mixed powder is 65 μm, and then the mixed powder, water glass, cold catalyst liquid and water Add it into a mixer, and stir at a speed of 25 rpm for 25 minutes to obtain a uniform mixed solution with good fluidity;

[0042] (2) Crystallization: the mixed solution obtained in step (1) was put into an autoclave and heated for 23 hours, the heating temperature was 85°C, the mixed solu...

Embodiment 3

[0047] In this embodiment, the molecular sieve manufactured by fly ash is prepared through the following steps:

[0048] (1) Mixing: the fly ash is subjected to magnetic separation-roasting-cooling pretreatment, wherein the magnetic separation adopts a high-efficiency magnetic separator for magnetic separation 4 times, and then it is roasted in a muffle furnace with a roasting temperature of 600°C for 2.5 hours, and cooled to At room temperature, put the pretreated fly ash, nano-anion powder, plant ash and caustic soda into a pulverizer to pulverize to obtain a mixed powder. The particle size of the mixed powder is 50 μm, and then add the mixed powder, water glass, cold catalyst liquid and water in sequence In the mixer, after stirring for 27 minutes at a speed of 30 rpm, a uniform mixed solution with good fluidity was obtained;

[0049] (2) Crystallization: the mixed solution obtained in step (1) was put into an autoclave and heated for 24 hours, the heating temperature was 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com