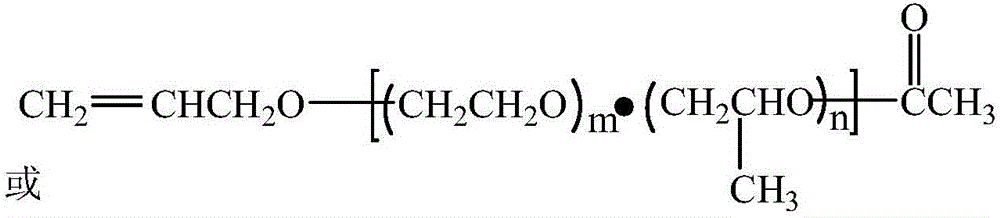

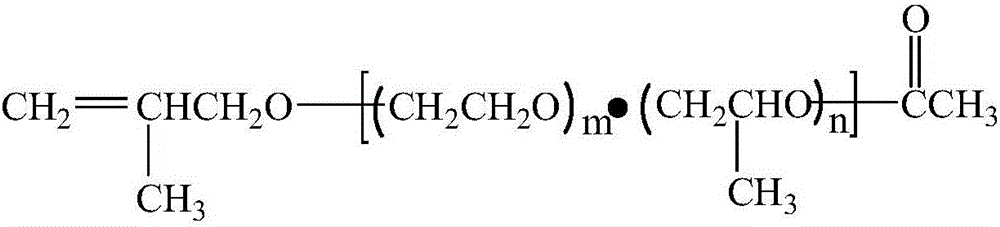

Acetyl terminated polyester and preparation method thereof

A technology of acetyl-terminated polyether, which is applied in the field of acetyl-terminated polyether and its preparation, can solve the problems of increased hydroxyl value and lower capping rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

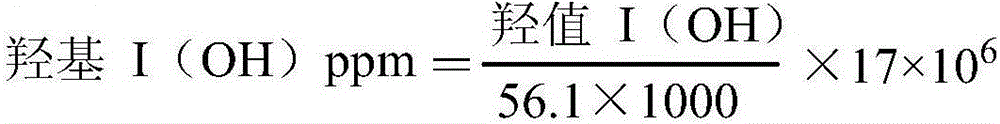

Embodiment 1

[0026] A kind of preparation method of acetyl-terminated polyether of the present embodiment, comprises the steps:

[0027] Add 1600 parts of allyl alcohol atactic polyether (M=5000) and 82 parts of acetic anhydride into the reactor, connect it to a condensing reflux device, raise the temperature to 130°C to 140°C, and reflux for 2.5 hours. Connect to the distillation device, adjust the amount of nitrogen gas, at 120°C ~ 130°C, vacuum degree -0.080MPa ~ -0.085MPa, deacidify by bubbling for 2.5 hours. Cool down to 70°C, transfer to falling film evaporator, deacidify for 1.5 hours under the condition of temperature 100-120°C, vacuum degree ≤100Pa, cool down to 70°C, add 20 parts of heptane, , under the condition of vacuum degree of -0.097MPa, desolventize for 1 hour, and cool down to 60°C to obtain acetyl-terminated allyl alcohol random polyether, with a hydroxyl content of 15ppm, an acetic acid content of 30ppm, an acetic anhydride content of 0ppm, and a moisture content of is...

Embodiment 2

[0031] A kind of preparation method of acetyl-terminated polyether of the present embodiment, comprises the steps:

[0032] Add 1600 parts of allyl alcohol atactic polyether (M=7000) and 68 parts of acetic anhydride to the reactor, connect it to a condensing reflux device, raise the temperature to 130°C-140°C, and reflux for 2.5 hours. Connect to the distillation device, adjust the amount of nitrogen gas to make the vacuum degree be -0.085MPa~-0.090MPa, and deacidify by bubbling for 3.0 hours. Cool down to 70°C, transfer to a falling film evaporator, deacidify at a temperature of 110-130°C, vacuum ≤ 100Pa for 2.0 hours, cool down to 70°C, add 18 parts of octane, at a temperature of 110°C-120°C , under the condition of vacuum degree of -0.098MPa, desolventize for 1.5 hours, and cool down to 60°C to obtain acetyl-terminated allyl alcohol random polyether, with a hydroxyl content of 10ppm, an acetic acid content of 30ppm, an acetic anhydride content of 0ppm, and a moisture conten...

Embodiment 3

[0036] A kind of preparation method of acetyl-terminated polyether of the present embodiment, comprises the steps:

[0037] Add 1600 parts of allyl alcohol polyoxyethylene ether (M=400) and 530 parts of acetic anhydride into the reactor, connect it to a condensing reflux device, raise the temperature to 130°C to 140°C, and reflux for 3.0 hours. Connect to the distillation device, adjust the amount of nitrogen gas to make the vacuum degree be -0.085MPa~-0.090MPa, and deacidify by bubbling for 3.0 hours. Cool down to 70°C, transfer to falling film evaporator, deacidify for 2.0 hours at a temperature of 110-130°C, vacuum degree ≤100Pa, cool down to 70°C, add 30 parts of octane, , under the condition of vacuum degree of -0.098MPa, desolventize for 1.5 hours, and cool down to 60°C to obtain acetyl-terminated allyl alcohol polyoxyethylene ether, the content of hydroxyl is 32ppm, the content of acetic acid is 55ppm, the content of acetic anhydride is 0ppm, and the moisture content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com