Flame-retardant anti-ultraviolet ointment waterproof coating and preparation method thereof

A waterproof coating and anti-ultraviolet technology, used in fire-resistant coatings, asphalt coatings, coatings, etc., can solve problems such as poor aging resistance, hidden safety hazards on construction sites, and waterproof failures, and achieve good waterproof performance and high bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

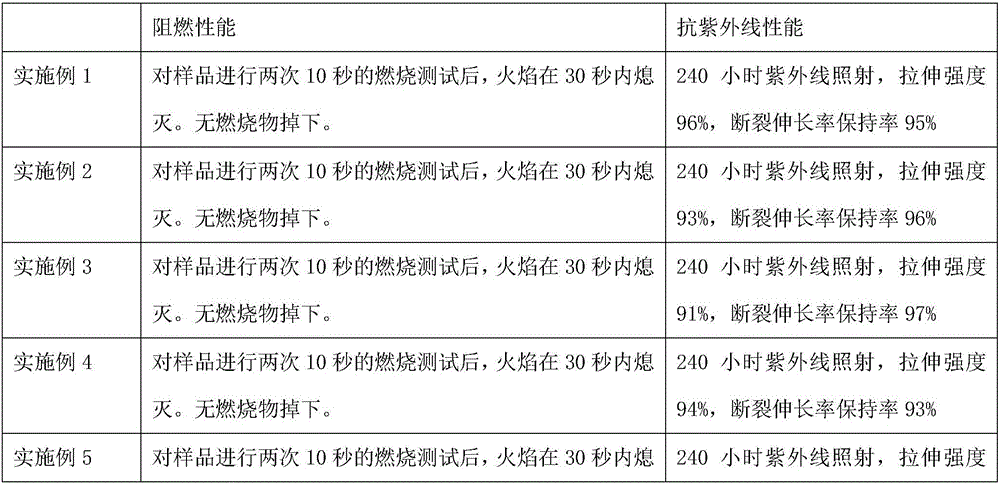

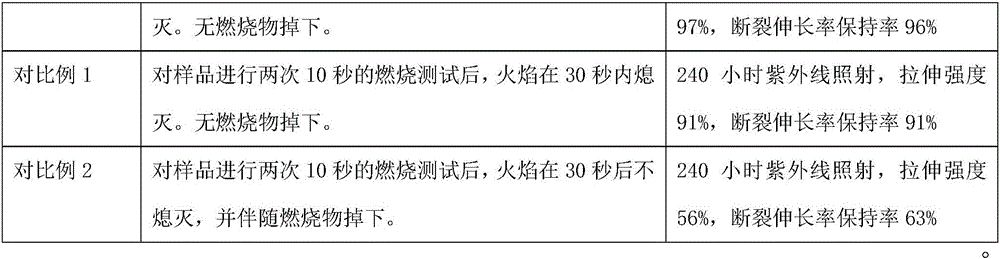

Examples

Embodiment 1

[0018] Step 1: Turn on the mixer, increase the temperature of the mixer to 150°C, take 3 parts of 10# asphalt, 50 parts of 70# asphalt, 12 parts of mineral oil, and 3 parts of styrene-butadiene-styrene block copolymer by weight , 4 parts of styrene-butadiene rubber, 5 parts of polypropylene particles, after stirring for 30 minutes, raise the temperature to 190 ° C for 3 hours;

[0019] Step 2: Lower the temperature to 170°C, add 8 parts of flame retardant, 3 parts of antimony trioxide, 8 parts of 2-hydroxy-4-methoxybenzophenone, and 10 parts of superfine talcum powder, and stir for 1 hour;

[0020] Step 3: Grind the mixture in Step 2 in a colloid mill for 3 hours, cool down to 150° C., and discharge.

Embodiment 2

[0022] Step 1: Turn on the mixer, raise the temperature of the mixer to 130°C, take 10 parts of 10# asphalt, 40 parts of 70# asphalt, 20 parts of mineral oil, and 10 parts of styrene-butadiene-styrene block copolymer by weight , 1 part of styrene-butadiene rubber, 15 parts of polypropylene particles, after stirring for 30 minutes, raise the temperature to 190 ° C for 3 hours;

[0023] Step 2: Lower the temperature to 160°C, add 3 parts of flame retardant, 8 parts of antimony trioxide, 2 parts of 2-hydroxy-4-methoxybenzophenone, and 15 parts of superfine talcum powder, and stir for 1 hour;

[0024] Step 3: Grind the mixture in step 2 in a colloid mill for 1 hour, cool down to 150°C, and discharge.

Embodiment 3

[0026] Step 1: Turn on the mixer, raise the temperature of the mixer to 140°C, take 6 parts of 10# asphalt, 46 parts of 70# asphalt, 16 parts of mineral oil, and 6 parts of styrene-butadiene-styrene block copolymer by weight , 2 parts of styrene-butadiene rubber, 10 parts of polypropylene particles, after stirring for 30 minutes, raise the temperature to 190 ° C for 3 hours;

[0027] Step 2: Lower the temperature to 170°C, add 5 parts of flame retardant, 5 parts of antimony trioxide, 5 parts of 2-hydroxy-4-methoxybenzophenone, and 13 parts of superfine talc powder, and stir for 1 hour;

[0028] Step 3: Grind the mixture in Step 2 in a colloid mill for 2 hours, cool down to 150° C., and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com