Side board ribbing distribution optimization method, side board and washing machine provided with side board

A technology of distribution optimization and rib-pressing, applied in other washing machines, design optimization/simulation, washing devices, etc., can solve the problems of easy resonance and insufficient rigidity of the edge plate, reduce vibration, solve static stiffness, fixed frequency characteristics, etc. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

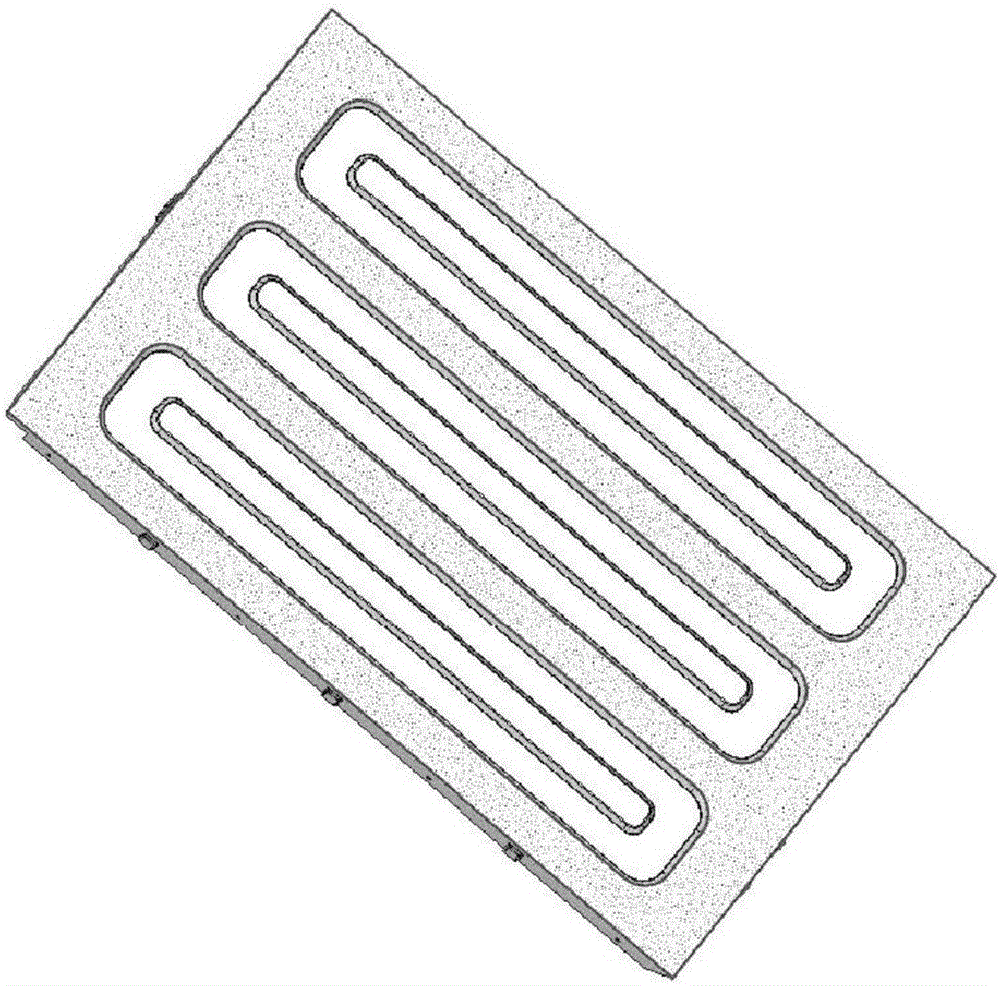

[0029] like figure 1 As shown, it is the original side plate model with vertical stiffeners.

[0030] The method for optimizing the distribution of side plate ribs of the present invention comprises the following steps:

[0031] (a) The modal analysis of the original model of the side plate is carried out by HyperMesh software, and the first-order fixed frequency f10 and the second-order fixed frequency f20 of the original model of the side plate are obtained;

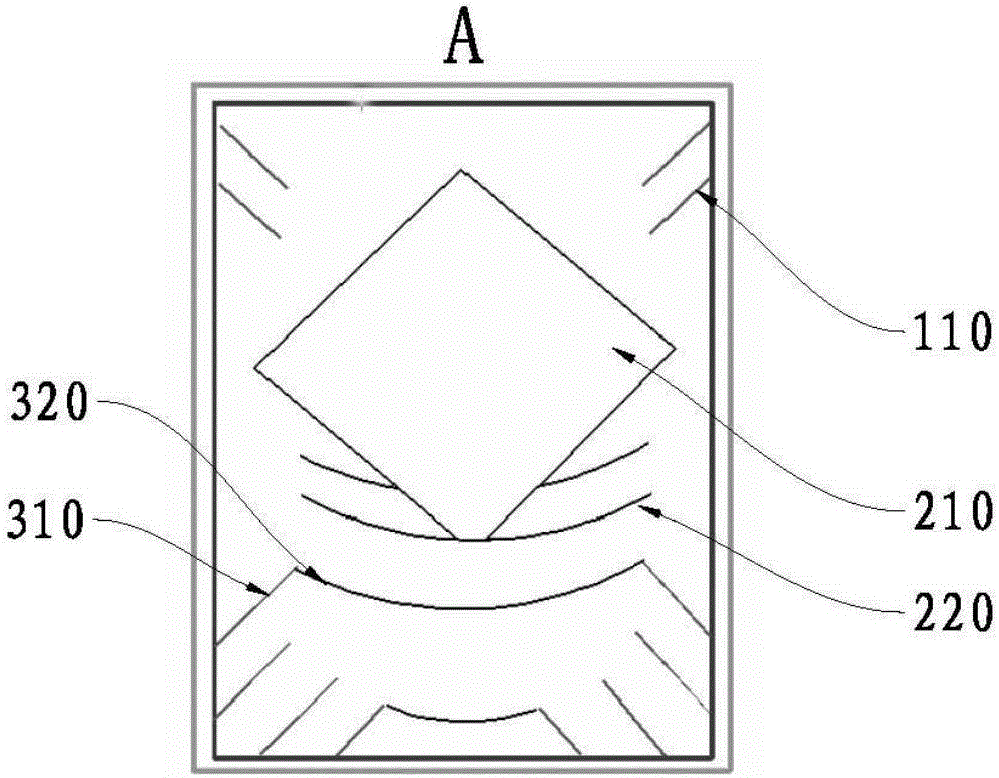

[0032] (b) Divide the design area and non-design area of the original model of the side plate, the design area is the main plane area of the panel, and the non-design area is the bending edge of the side plate and the screw installation area; and set the parameters of the reinforcement and the reinforcement method, specifically The structural parameters are: rib height 5mm, rib width 5mm~30mm, stamping angle 45°~60°, rib pattern distribution is concave rib symmetrical distribution; under the constraint of a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com