Threaded prefabricated uhpc pipe pile and its manufacturing and construction method

A construction method and pipe pile technology, applied in the direction of manufacturing tools, sheet pile walls, foundation structure engineering, etc., can solve the problems of large internal force, slow piling speed, pull-up damage, etc., and achieve large mechanical bite force and friction resistance, The effect of speeding up the piling speed and easy forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

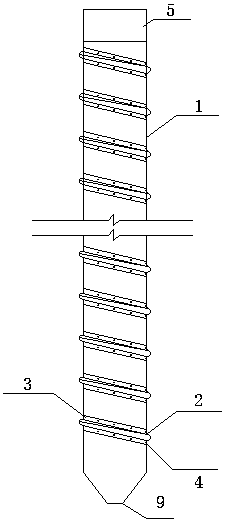

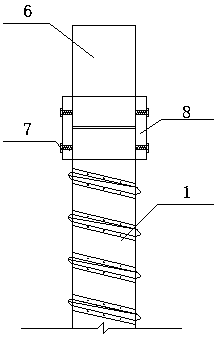

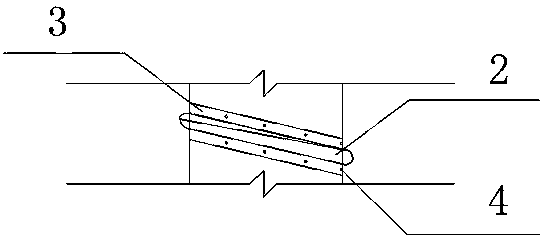

[0017] Such as Figure 1-3 As shown, a threaded prefabricated UHPC pipe pile includes a concrete pipe pile body. The concrete pipe pile body consists of a pile cap, a pile body, and a pile bottom cone. The pile cap is arranged on the top of the pile body, and the pile bottom cone is an inverted cone and Set in the lower part of the pile body, the outer periphery of the pile body is provided with spiral concrete ribs from top to bottom, the concrete ribs spirally extend from the pile bottom cone to the pile cap, and the surface of the concrete ribs is equipped with alloy steel sheets, which can be well The concrete rib is protected and the concrete pipe pile body is like a drill with a blade.

[0018] In this embodiment, the alloy steel sheet is wrapped outside the concrete rib, and the alloy steel sheet is connected to the pile body through expansion screws.

[0019] In this embodiment, the concrete pipe pile body and the concrete ribs are both made of ultra-high performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com