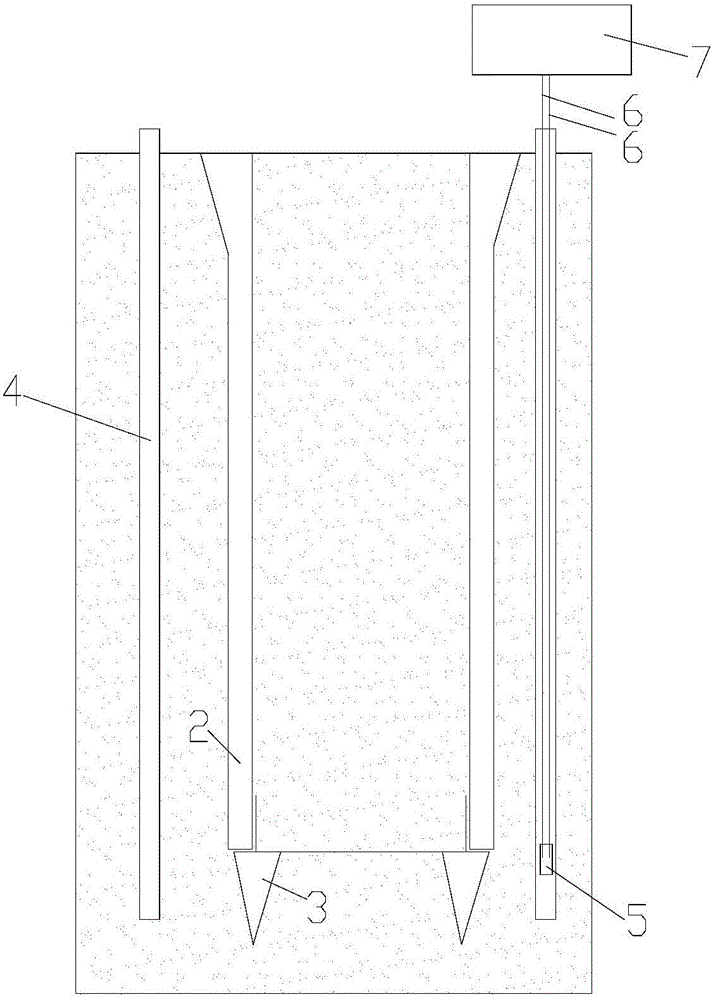

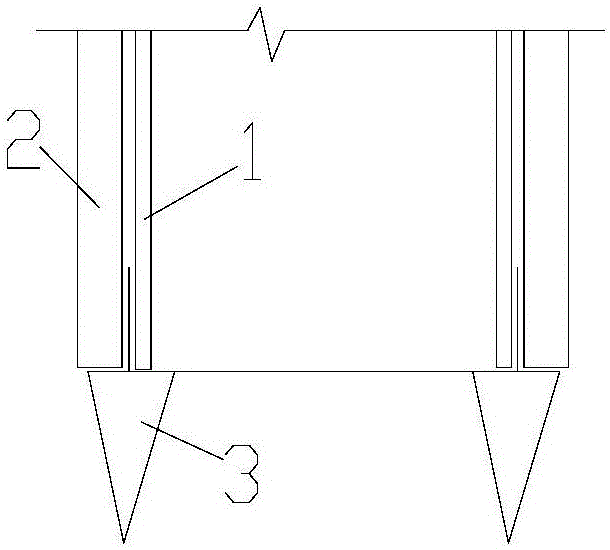

Construction method of composite pile foundation

A construction method and technology of composite pile foundation, applied in foundation structure engineering, foundation structure test, sheet pile wall, etc., can solve the problems of limited bearing capacity, engineering hidden dangers, poor durability, etc., and achieve low impact and high reliability , The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The ground elevation of a project site is 125-2170mm. The landform of the site was an intertidal zone before the early 1990s, and it was formed by artificial embankment reclamation. The current landform type is coastal plain. The strata in this field are divided into 4 major layers from top to bottom within the exploration depth range.

[0016] The first layer: plain fill, layer thickness 1100-7180mm. Variegated, loose, mainly composed of gravel, block stone, sand and other pond dregs and construction waste, the particle size of the gravel is mostly 5-40cm, and a few are larger than 100cm, with poor gradation, extremely uneven, poor sorting, and intergranular Filled with sand. The properties are uneven, the structure is loose, the soil layer is highly discrete, anisotropic, and the layer thickness varies greatly.

[0017] The second layer: silty clay interlayer, layer thickness 170mm. Grey-yellow, wet, soft plastic, sandy. Medium dry strength, medium toughness, no s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com