A light-weight decorative molding or component and its manufacturing method

A technology of decorative lines and manufacturing methods, applied in the direction of building structure, adhesive type, adhesive, etc., can solve the problems of ineffective heat preservation, transportation, inconvenient installation, low structural strength, etc., and achieve good heat preservation effect and long service life Long-term, high product consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

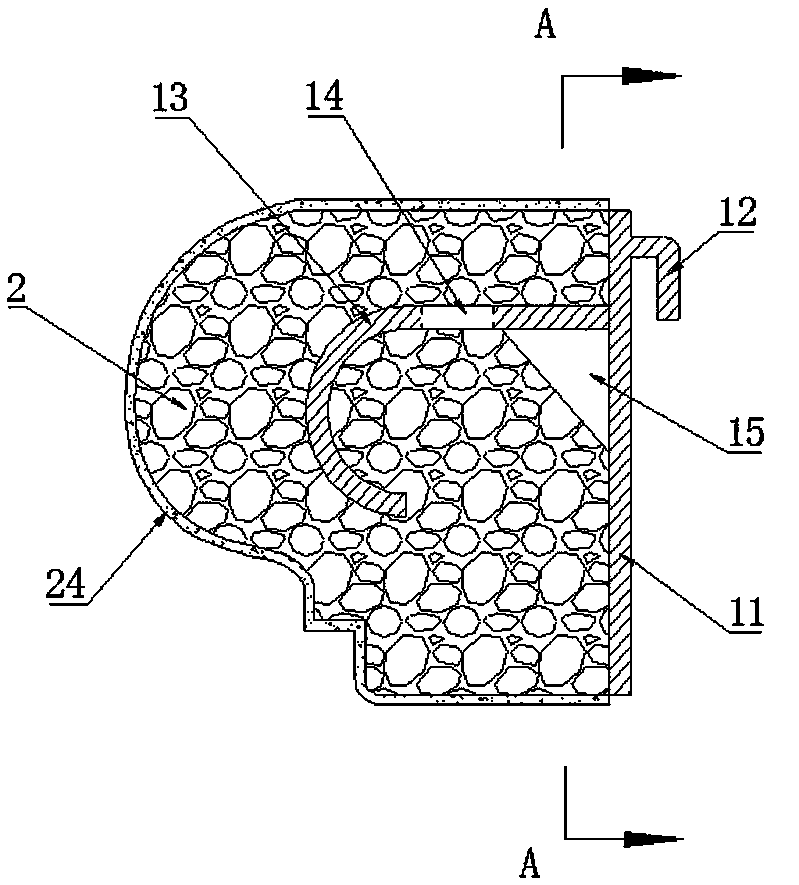

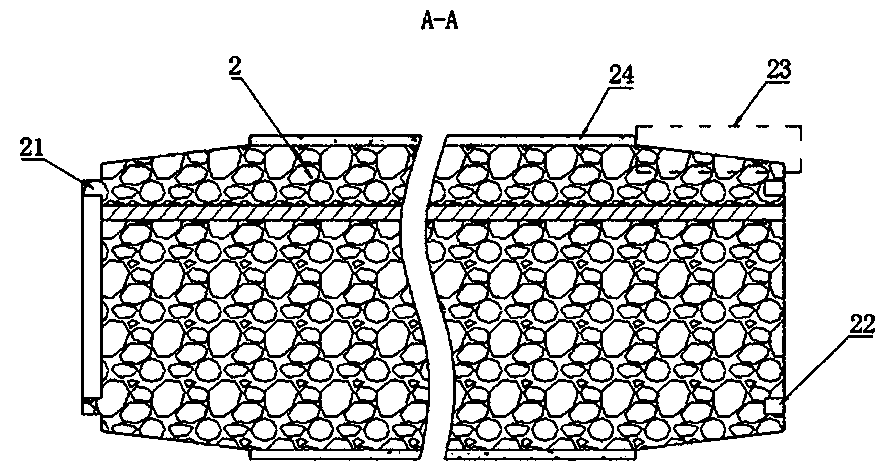

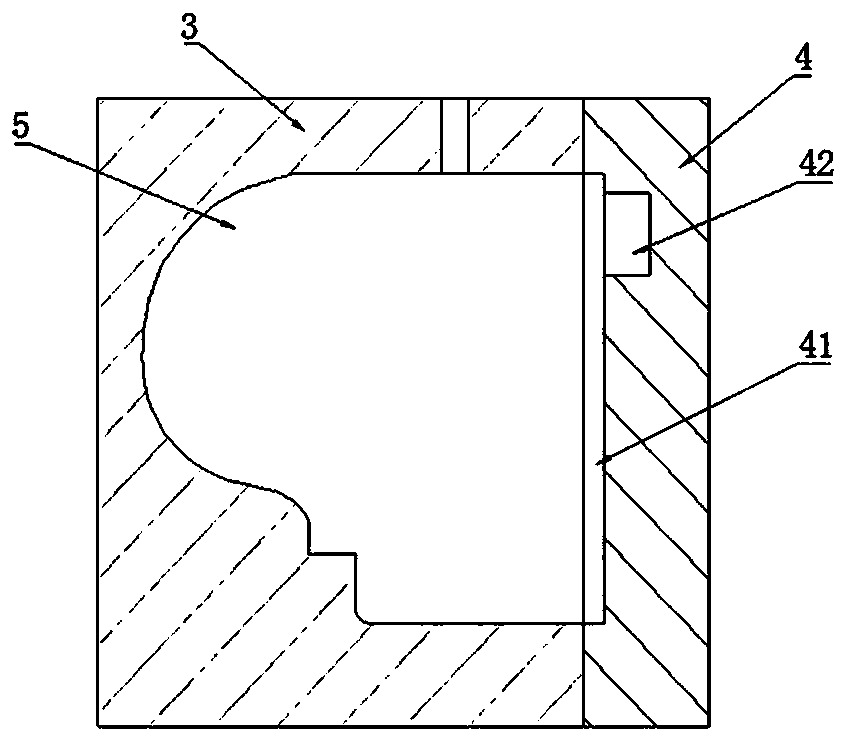

[0027] like figure 1 , 2 , the light-weight decorative lines or components of the present invention include a metal skeleton for enhancing the strength of the decorative component, the metal skeleton has a strip plate body 11, and the back side of the plate body 11 is provided with a connecting piece 12 or a connecting structure, the connecting piece 12 It is used for connecting and fixing the decorative components and the building decoration brackets in the later stage. The connecting parts 12 generally adopt the forms of hooks, clips, bolts and the like.

[0028] An embedded part 13 extending along the long axis direction of the strip-shaped plate body is connected and fixed in the front middle part of the plate body 11. The cross section of the embedded part 13 is a "J" shape with a bent front end. The J"-shaped rear end is vertically connected and fixed to the front of the board body, and the bent end of the embedded part 13 is bent along the short axis direction of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com